Conductive elastomers

- Technology

- EMI shielding materials

- Partner

- MTC

Constant conductive elastomers are seals for the highest demanding applications, composed of a homogeneous mixture of conductive particles in elastomers.

Conductive coated silicone are silicone cords with an electrically conductive coated skin and a number of very soft gaskets with good shielding properties.

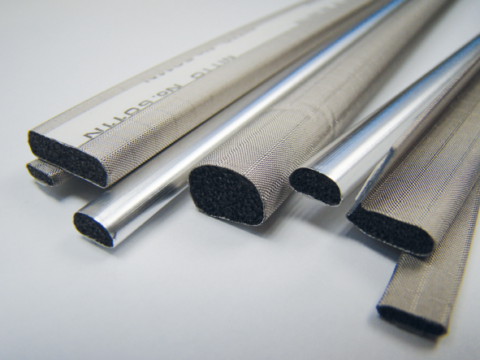

Coextruded elastomer profiles consist of a conductive and a non-conductive elastomer. In addition to excellent EMC shielding properties, the profiles which are produced in a single extrusion process also offer high protection against environmental influences.

Used in a range of different applications, these elastomers mainly fit empty space and obtain excellent conduction and seal to different IP.

Range features

A high level overview of what this range offers

- Constant conductive elastomers

- Conductive coated silicone

- Coextruded elastomers

- Oriented wires in silicone

- 140 contact points/cm² ensure optimum contacting of the gasket with other metal surfaces. The gasket material can be mounted with commercially available silicone adhesive (e.g. momentive RTV103Q-732)

- The conductive component achieves shielding values between 80 and 120 db depending on the filling material, the non-conductive component IP protection up to IP68 in a temperature range of -55 to +160 °C

- Stamped or molded components are manufactured according to customer requirements

- Wires in silicone are a sealing material consisting of fine Monel or aluminum wires. The wires are vulcanized into solid or foamed silicone perpendicular to the surface

What’s in this range?

All the variants in the range and a comparison of what they offer

| Model | Model | Available in | Fillers |

|---|---|---|---|

Constant conductive elastomers | Highest environmental protection (up to IP68) Use of fluoro silicone if material should be resistant against aggressive substances. Stamped parts or moulded parts according to application need. |

|

|

Conductive coated elastomers | Ideal properties concerning pressure and resistivity to age. Excellent electrical conductivity Foamed or extruded silicone as core material. | extruded profiles:

|

|

Coextruded elastomers | Combi-gasket for EMC and environmental protection. Highest environmental protection (up to IP68) of the non-conductive area. Use of fluoro silicone if material should be resistant against aggressive substances. Cost-effective solution compared to two separate gaskets. Customer-specific manufacturing. |

|

|

Oriented wires in silicone | Available as sheet material, die-cut gasket or strip material. In solid or foamed silicone. Best contacting of the gasket with other metal surfaces. High mechanical strength and elasticity. Excellent dust and splash water protection (IP 65). Use of fluoro silicone possible (if contact with aggressive fluids). |

| Models:

|

FAQs

for Conductive elastomers

Conductive elastomers are sealing materials composed of a homogeneous mixture of conductive particles (e.g., silver, nickel, graphite) within an elastomer matrix. They offer excellent electromagnetic interference (EMI) shielding while also providing a reliable mechanical seal. Thanks to their electrical conductivity, conductive elastomers are ideal for applications where both sealing and EMI protection are essential.

Electrically conductive elastomers combine mechanical flexibility with high electrical conductivity. Unlike standard gasket materials, they enable electrical continuity across enclosures, effectively creating a Faraday cage. This is crucial for meeting strict EMC (electromagnetic compatibility) requirements in modern electronic designs.

Several types of conductive elastomers are available:

- Constant conductive elastomers: provide uniform conductivity throughout the material – ideal for high IP-rated sealing.

- Conductive coated silicone: silicone core with an electrically conductive outer layer – great for soft, low-resistance gaskets.

- Coextruded elastomers: combine conductive and non-conductive sections – offer EMC shielding and environmental protection in one profile.

- Oriented wires in silicone: vertical metal wires embedded in silicone – best for applications needing strong EMI shielding and mechanical strength

A well-designed conductive elastomer gasket can achieve shielding effectiveness between 80 and 120 dB, depending on the type of conductive filler used (e.g., silver, nickel, graphite). This makes them suitable for demanding environments such as military, aerospace, medical, and industrial electronics.

The filler material determines both the electrical and chemical properties:

-

Nickel-plated graphite: cost-effective and widely used in industrial applications.

-

Silver-plated copper: excellent conductivity, though less corrosion-resistant.

-

Silver-plated glass/aluminum: balance between conductivity and environmental durability. For harsh environments, fluorosilicone is recommended as the elastomer base due to its chemical resistance.

A coextruded elastomer integrates both conductive and non-conductive components in a single extrusion process. This dual-function profile offers EMI shielding and environmental sealing (up to IP68). A standard conductive gasket material, on the other hand, is typically uniform and fully conductive – ideal for pure EMI shielding tasks.

Conductive elastomer gaskets can be:

- Die-cut or molded to custom shapes

- Self-adhesive backed

- Bonded using silicone adhesives like RTV103Q-732

- Installed into grooves using extruded profile formats These options allow flexible integration into different enclosure designs.

Depending on the design, conductive elastomers can reach protection levels up to IP68. Especially constant conductive elastomers and coextruded elastomer profiles using fluorosilicone can withstand exposure to liquids, dust, and chemicals – all while maintaining excellent EMI shielding.

Conductive elastomers are widely used in sectors where EMI protection and sealing are critical:

- Aerospace and defense

- Telecommunications

- Medical devices

- Automotive electronics

- Industrial control systems

The unique properties of conductive gasket material make them suitable for applications requiring both shielding and sealing.

Key selection criteria include:

- Operating temperature range (e.g., -55 to +160 °C)

- Shielding performance (in dB)

- Compression and contact geometry

- Chemical resistance – fluorosilicone offers enhanced durability

- Required IP rating Working closely with the manufacturer ensures a conductive elastomer solution tailored to your specific application.