The shifting currents of the electric vehicle charging market

In either approach, there will be a system design that includes all the necessary features for effective charging management. We offer a portfolio of specialist magnetic, power, wireless, sensors, imaging, and photonics technologies from carefully selected partners.

To discover how we can help, we have outlined two routes, board-level, and system-level integration.

Our approach

Together, with our Field Sales engineers, we can support you at every stage of your design process, from concept to production, creating a unique electric vehicle charging system to meet the industries growing needs. Our approach to achieving this is simple: Consult. Design. Integrate delivered with the support of our Technology Centres.

We have access to market-leading customised magnetic components manufacturer specialists such as Myrra, Flux, and Noratel. You will receive the same technical support and competitive prices. Our in-depth experience with customised power supplies and magnetic components is a clear advantage when designing products for EV charging applications.

Designing the power conversion section:

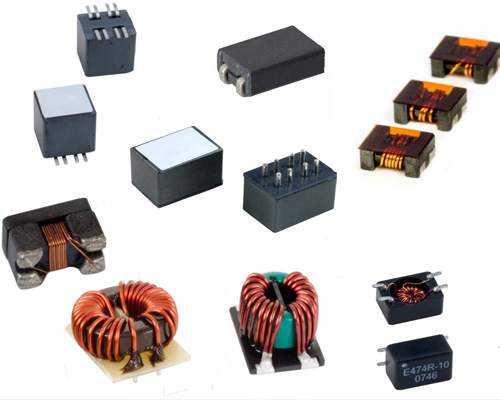

- The key components in designing the power conversion module are inductors and transformers, and the selection of the right magnetic core is extremely important to achieve the best efficiency of the converter. We can also offer SMD power inductors, EMI filters, current sensors, temperature sensors, thermally conductive products, and frequency controllers. This segment of the brochure covers all these components for power modules.

Designing the full system:

- When designing a charging solution by integrating blocks, fast DC-charging modules, AC/DC converters, high-power transformers, EMI filters and shielding, current transformers and power supplies are some of the products we offer.

- Payment services and user interfaces: 2G/3G/LTE modules, LoRa, Wi-Fi, Bluetooth®, and RFiD technologies are also available for system design solutions.

Gehe zu:

Designing the power conversion section

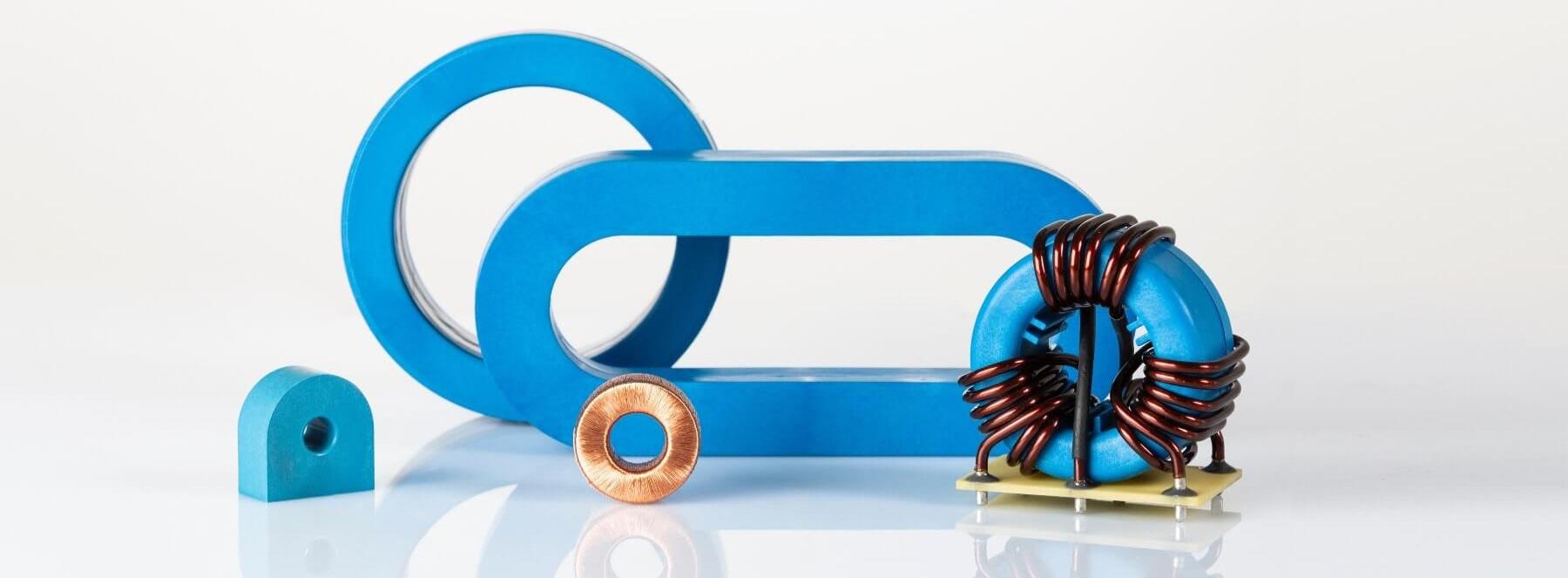

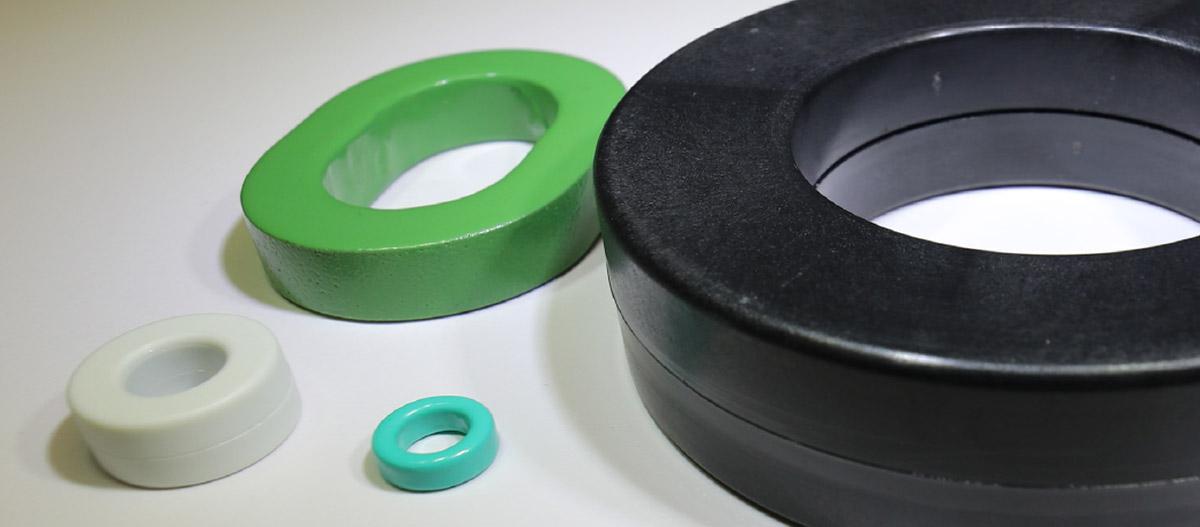

Magnetic cores for inductors and transformers

When designing inductive components like transformers and inductors, choosing the right material is the first challenge. There are over a dozen material classes, with a huge variety of sub-classes, brands, grades, and types. A developer has to match their application's requirements with the parameters of each material and give consideration to the cost implications.

A developer needs to match their application’s requirements with the parameters of each material and give consideration to the cost implications. Our portfolio covers a wide range of specialist soft magnetic materials including EDGE, XFlux, Kool Mu Max from Magnetics Inc., Iron Powder from Micrometals as focus materials for inductors; Amorphous, Nanocrystalline from our Acal BFi kOr product line, and ferrites from Ferroxcube for transformers. We can help you select, source, customise, stock, and integrate soft magnetic cores.

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|||

| See range | See range | See range | See range |

Common mode chokes for EMI filters - cores and components

When designing modern and often complex integrated systems, engineers must consider the possibility of electromagnetic interference (EMI), which affects the performance of the system and can lead to a failure to meet regulatory standards.

To contain conducted emissions the usual solution is to add a filter at the input stage of your system and common mode chokes (CMC) are the basic component of the filter. This allows the target signal to pass unaffected, whilst filtering out undesired signals.

The expertise within our in-house Magnetic Products Technology Centre enables us to select the right material and design the best core to build your common mode choke. We offer nanocrystalline (see inductors and transformers section) and ferrite cores.

We can also offer a list of ready-made common mode chokes from our suppliers Magnetec and Laird.

|

|

|

|

|

|

|

|

|

Common mode chokes from Magnetec |

Common mode chokes from Laird |

|||

|

|

|

|

|||

| See range | See range | See range | See range |

Designing custom magnetics

When designing a power conversion module for a charging application, magnetic components are vital and need to be designed using the competencies of soft magnetic cores, wires, insulation, plastics, and heat dissipation.

With a well structured team of technical support specialists in Europe, we are able to design with you custom solutions for magnetic cores or components within power conversion applications.

Our Magnetics Products Technology Centre can develop a solution to achieve your goals, whether your need is simple or complex.

- Consultancy on soft magnetic cores. We not only select the best technology for you, but we can also design the best-suited core for your application

- Starting from your basic specifications, we design the inductive component and produce rapid prototypes to test the concept

- Manufacturing of the components

- Setup a dedicated logistic strategy to secure your supply chain

Typical products we can develop are common mode chokes, PFC chokes, transformers, EMI filters, and 50Hz safety and monitoring components (current transformers and RCDs).

Thermally conductive products

High current power conversion produces heat that must be dissipated safely to avoid overheating causing EMI issues or even premature failure of electronics inside the application.

We offer market-leading thermal interface materials from MTC, that combine high thermal conductivity and low viscosity whilst maintaining insulating properties.

|

This customisable range includes: |

Common characteristics of all these materials are: |

|

|

|

|

Temperature sensors

Temperature sensors are used across a range of applications in electric vehicles, such as temperature monitoring of the charging cable, charging pile and Battery Management System (BMS).

These applications call for sensors that are suited to harsh environments, accurate measurement, fast detection of a change in temperature, enhanced reliability and quality.

With Shibaura’s high-quality glass encapsulated thermistors, which provide superior performance, quality and reliability, our temperature sensors are able to withstand high voltages and temperatures up to 1000°C.

|

Image

|

|

Image

|

Shibaura MP3 series |

Shibaura EP2 series |

|

|

Shibaura’s MP3 thermistor sensor with Heat, oil and solvent proof, making them ideal for motor coil temperature detection applications. |

Shibaura’s EP2 thermistor sensors with a glass encapsulated thermistor.

|

Designing the full system

DC and AC power conversion

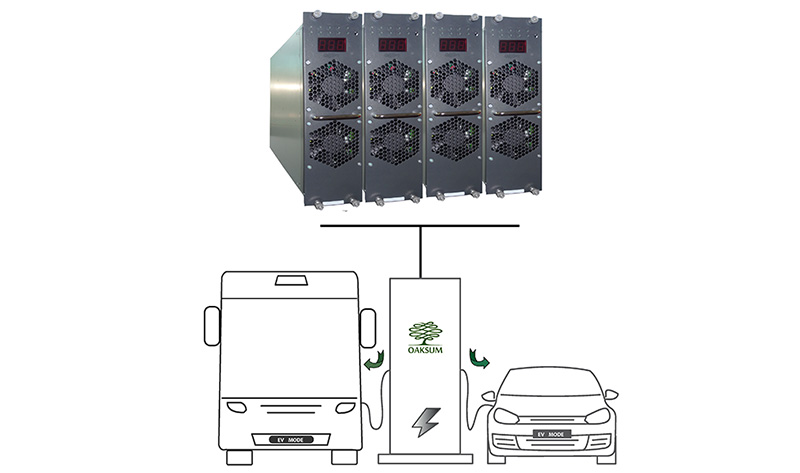

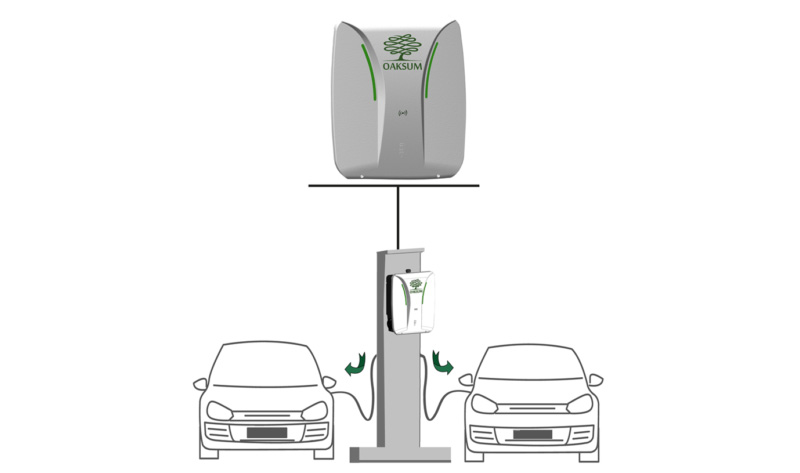

When designing a charging solution by integrating blocks, fast DC-charging modules, AC/DC converters, high-power transformers, EMI filters and shielding, current transformers and power supplies are some of the products we offer.

Payment services and user interfaces: 2G/3G/LTE modules, LoRa, WiFi, Bluetooth®, and RFiD technologies are also available for system design solutions.

|

|

|

|

|

|

These modular AC/DC power-dense converters are specifically designed for fast DC charging for E-cars and buses, service vehicle operators, EV manufacturing lines, EV workshops, and EV fleet operators.

|

OAKSUM’s smart AC EV chargers are designed for maximum charging performance combined with high energy efficiency. The IP65 casing gives a robust and compact weatherproof construction.

|

|

|

|

||

Customised converters and chargersWe work in partnership with OAKSUM to customise and manufacture converters and chargers for electric vehicles. Together, we have in-depth experience and a wide variety of services to help with the process of finding the right power supply for your specific requirements. OAKSUM also offers a range of options to brand and customise the product look and feel, including a choice of case colour, customer’s logo, and branding. |

||

Protecting users from your EV charging system

|

Current sensitivity components

Electric vehicle charging systems require the capability to measure current in order to detect uncontrolled situations which may cause permanent system failures.

Our Magnetic Products Technology Centre offers cores for different types of RCDs (Residual Current Devices). Electric vehicle charging requires all-current sensitivity, detecting pure DC currents and any currents with higher frequencies above 50Hz. We are able to tune properties (hysteresis loop shape, permeability, and temperature behaviour) of nanocrystalline cores ( Acal BFi kOr 118 and 120).

- Optimum combination of high linearity and highest permeability

- Negative temperature coefficient µ(T) (as standard)

- Plastic case or epoxy coated for example as RCCB core: Bdyn/Bsin > 0.85 at µmax = 150.000 and >0.80 at µmax = 200.000

Transformers

When power management ratings increase, you may need 50/60Hz transformers to connect your charger system to the grid. We offer a specialist range of transformers designed for smoothing in rectifiers, reducing short-circuit currents, AC filtering, and high-frequency switching.

These transformers are manufactured according to a customer’s exact requirements. Noratel is able to design and produce anything from small single-phase toroidal to large tri-phase EI transformers with heavy current coils for larger electric vehicle charging installations, with everything developed in close co-operation with the customer.

|

EMI shielding

For safety and reliability, it is critical that charging stations meet the industry’s full requirements. Electric vehicle charging stations equipped with advanced capabilities such as power electronics and cloud-based communications fall under the class of devices that require EMC testing and certification.

To help protect your device we offer a broad range of components and materials for the shielding of EMI, such as:

- Fabric-over-foam (FoF) gaskets, electrically conductive foams, elastomers, tapes, and contact springs

- Shielded windows, metal honeycomb vent panels, and fan vents

- Metal contact springs and pads

- FOF made of aluminium foils or copper-nickel fabric

|

Image

|

Image

|

Image

|

||

|

|

Fibre optic temperature probes |

||

|

Teledyne FLIR's infrared sensors have a proven history However, in an electric vehicle application, they can be used to optimise system management, detecting heat spikes and they can be used to improve the accuracy of vehicle detection in automated electric vehicle charging facilities. Teledyne FLIR offers a range of SWIR, MWIR, and LWIR infrared sensors to provide accurate data managing your electric vehicle charging system. Need help with a custom IR sensor? Our infrared specialists offer personalised and responsive support at every stage of a project, providing samples and technical support. We also offer an exclusive range of specialist lenses that can be integrated and configured by our Infrared Imaging Technology Centre. |

Our specialist products provide the electric vehicle The multi-segment optical sensing technology provides narrow to wide fields of view with lateral discrimination, enabling multiple object detection and distance measurements.

|

Advanced Energy Luxtron’s FOT probes (Fibre Optic Temperature probes). Suitable for eliminating weak insulation points within electric motors/ generators, understanding precise temperature limits and behaviour of battery cells within Li-Ion battery packs, temperature testing within charging ports and power cables, and direct temperature measurement of power electronics. Advanced Energy Luxtron FOT probes are self-calibrated and immune to EMI, Microwave and RF radiations. |

Intelligent wireless connectivity

Electric vehicle charging infrastructure requires the highest level of performance to overcome the connectivity and logistical challenges of deploying across large areas.

Using the right technology is key for critical applications such as remote operation, predictive maintenance, payment, and energy control functions by overcoming the difficult coverage, capacity, and cost barriers for multiple locations at any one time

With modules designed specifically for remote device deployment, you can design using best-in-class readyto-connect, future-proofed modules that provide SIM connectivity to devices anywhere in the world.

Cellular modules

|

Image

|

|

Image

|

|

Fibocom FM160 series |

|

Offering low-cost and extremely low-power technology, covering worldwide 2G/3G/4G networks.

|

Offering highly integrated 5G wireless communication modules which come either in a M.2 form factor interface or a solder-down LGA variant.

|

|

| See range | See range |

LoRaWAN

|

Image

|

|

Image

|

|

|

|

|

Designed to enable very low power, long-range devices for highly sensitive communication to easily be conveyed at regional, national, and even global levels. This also provides significant advantages in both blocking and selectivity over conventional modulation techniques, solving the traditional design compromise between range, Interference immunity, and energy consumption.

|

Offering a unique combination of two leading IoT radio technologies in one class-leading miniaturised package. With integrated BLE and LoRa, these modules offer the long-range capability of LoRa for data transmission across distances, combined with the high-throughput flexible service of BLE for a short-range connection.

|

|

| See range | See range |

Supporting you throughout every stage of your design

Our Technology Centres are fundamental within our consultative, design-led approach. At each facility, we have a team of highly experienced industry experts in their respective fields ready to accelerate and enhance your electric vehicle application.

When designing an AC/AC or AC/DC EV charger, we can collaboratively work with you throughout each project stage.

- Advice and recommendations on components, wiring harnesses, and PCB design and layout, through to the integration of subsystems including power modules, connectivity modules or security features

- Designing inductive components, power supplies, and connectivity modules. Our focus on customer service, combined with our expertise, experience, and specialist equipment means we translate your requirements into a reliable, cost-efficient design, whether starting from scratch or modifying an off-the shelf product. We can then extensively test and verify these designs with the required test equipment

- Support during the certification phase, by designing or supplying EMI shielding and filters or IP protection gaskets. Our pre-compliance ensures that your design will meet the appropriate standards

- Management of production and complete supply chain including quality assurance. With a choice of certified manufacturing partners to enable a best fit for your unique requirements, we provide the most efficient capabilities matching your design, volume, and destination

Wie können wir helfen?

Wenn Ressourcen oder Kapazitäten begrenzt sind, können Sie sich auf unser Wissen und die Unterstützung durch unsere Technologiezentren verlassen, denn wir unterstützen Sie vom Konzept bis hin zur Produktion.

Dank unserer Technologiezentren haben Sie Zugang zu einer großen Auswahl an kundenspezifischen Lösungen. Wir entwickeln zusammen mit Ihnen Konzepte für Ihre Applikationen und Anwendungen und helfen Ihnen dabei diese in die Realität umzusetzen. Erfahren Sie, wie wir Sie durch unsere Technologiezentren unterstützen können.

Germany

Germany