Surface mount device contact pads

- Technology

- Metal parts

- Partner

- MTC

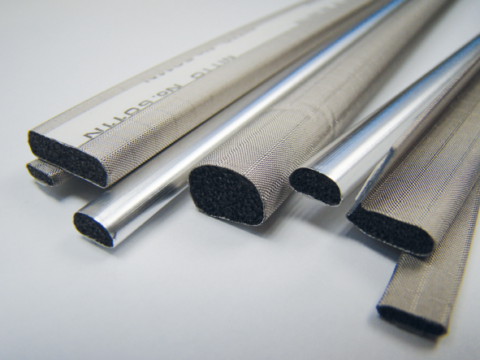

Surface mount device (SMD) contact pads are used exclusively on the printed circuit board. Due to their electrical and physical properties, SMD contact pads are an excellent alternative for the grounding of PCB.

In contrast to fabric over foam gaskets which do not have high temperature resistance, and which are not solderable, SMD provide a cost effective solution for printed circuit board (PCB) contact to ground vs metal parts and spring.

Range features

A high level overview of what this range offers

- Make contact between the PCB’s earth and the housing

- Offer a low ohm HF connection between the earthing points of two PCBs positioned one on top of the other

- Earth cooling units on a high-frequency basis

- Connect signal and power supply cables between two PCBs

- Connect the PCB and elements which are not on the PCB (for example an embedded antenna) or to create external connections

- Excellent electrical conductivity

- High heat resistance (max. 300 °C)

- High abrasion resistance

- Very good spring characteristics

- SMT mountable characteristics for automatic soldering procedure

- High adhesion after SMT

- Type S: silicone core coated with conductive silicone paste and a solderable tin-plated copper foil on the bottom

- Type W: silicone rubber coated with conductive solderable film.

What’s in this range?

All the variants in the range and a comparison of what they offer

| Model | Width | Height | Length |

|---|---|---|---|

SMG-S | 2,00 mm | From 0,8 to 2,5mm | From 1 to 1,8mm |

SMG-W | From 2 to 10mm | From 0,7 to 12mm | From 1 to 8,4mm |