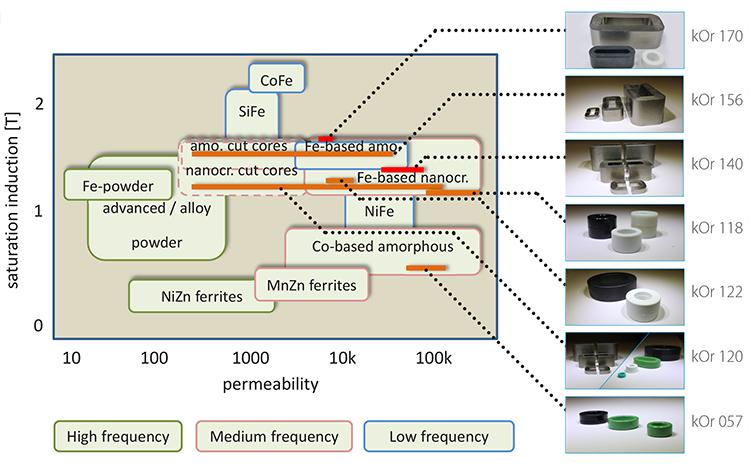

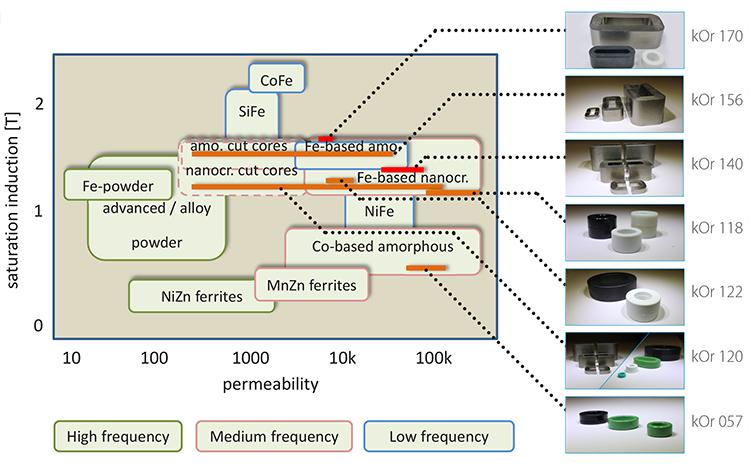

kOr - high quality amorphous and nanocrystalline cores

Acal BFi is a specialist provider of soft magnetic materials providing amorphous and nanocrystalline cores through our kOr product line. We are committed to providing consistent and high quality cores through stable raw material's base, high-tech efficient production, and rigorous testing from our in-house engineering team.

Acal BFi's kOr product range provides amorphous and nanocrystalline tape wound cores in a huge range of shapes and sizes. Custom and enhanced designs can be realised through our customisation service to meet your specific application requirements.

Jump to:

Need to speak with an expert?

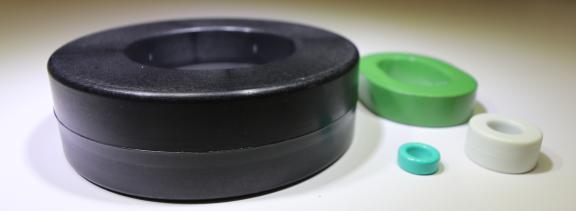

kOr 057

kOr 057 is a Co-based amorphous material with superior soft magnetic properties like small coercivity and zero magnetostriction. B(H) characteristics can be tailored: With linear F-loop, kOr 057 reach permeabilities of 100.000 - 200.000. These cores are perfect for communication applications like signal transformers. With rectangular Z-loop, they are mainly used in switching applications like MagAmps, when low losses are required or low saturation induction of 570 mT and hence small flux swing provide advantages.

|

Features

Benefits

|

kOr 118

kOr 118 is a nanocrystalline material specifically optimised for very high permeability and excellent linearity at low frequencies (50 Hz). This material has been developed especially for RCCB applications, and can also be used for CTs or CMCs where no DC parts (as common mode current in case of CMCs) are present. Cores are packed in plastic cases; Epoxy coating is possible with minor influence on linearity for µmax up to 150.000.

Features

- Optimum combination of high linearity and highest permeability:

for example as RCCB core: Bdyn/Bsin > 0,85 at µmax = 150.000 and >0,80 at µmax = 200.000 - Negative temperature coefficient µ(T) or constant permeability over-temperature adjustable

Benefits

- Available in plastic case or Epoxy coated (up to permeability of 150.000) to minimise required space

- Small tolerances available by sorting into groups

kOr 120

kOr 120 products are made of an iron-based nanocrystalline material optimised for power and EMI applications. They have high saturation flux density, low losses, high permeability up to 100kHz, and low magnetostriction. Different B(H) characteristics are available. With a flat hysteresis loop (F-loop), low remnant flux Br, and adjustable permeability between 25.000 and 120.000 (at 10kHz), they are the preferred choice for mid-frequency power applications and common mode chokes with wideband attenuation. Our standard 120-TB-series includes selected core sizes in plastic cases with a lower limit of specified permeability between 25.000 and 80.000 (10 kHz). The variant kOr 120HF with ultra-thin ribbon is the perfect choice for high frequency: transformers for >30 kHz, and optimised CMCs. With rectangular Z-loop, they are a cost-effective alternative for MagAmps and other switching applications.

Features

- High saturation flux density (1.2 T)

- High Curie temperature (580ºC) and excellent temperature characteristics

- Near-zero magnetostriction

Benefits

- Applicable for transformers and common mode chokes

- Low losses, especially using kOr 120HF, allow high flux density at medium frequencies, ie reduced space

- Standard sizes with adjustable permeability ie tailored inductance and DC tolerance

- Size and finishing can be customised easily, available also as cut cores

kOr 122

kOr 122 extends our nanocrystalline material cores range to permeability down to 4000. Cores are ideal for use in transformers and CMCs with medium non-balanced common mode current. They show high linearity µ(IDC) and frequency behavior µ(f), so permeability at 100 kHz is very close to 10- kHz value. These cores are offered in a plastic case.

Features

- High saturation flux density (1,2 T)

- High linearity µ(IDC) and µ(f)

- Excellent long-term stability even at high temperature

Benefits

- Applicable for transformers and Common Mode Chokes with high currents

- Big variety for shape, size, and finishing according to space and mechanical requirements, for example, big oval cores

kOr 140

kOr 140 is a further development of kOr 120 / kOr 122 to increase the flux density but keeping a good loss level. Target applications are mid-frequency transformers and Common Mode Chokes for high nominal and/or non-balanced currents. The permeability can be adjusted between 30.000 and 70.000 for cores with F-shape hysteresis loop. Cores are available in a plastic case and Epoxy impregnated, with or without cuts. A version with ultra-thin ribbon, resulting in lower losses and higher 100 kHz permeability is also available for this material.

Features

- Improved saturation flux density (1,4 T)

- Low losses, further optimised with kOr 140HF

- Low magnetostriction allowing also impregnated cores

Benefits

- Applicable ideally for transformers

- Even smaller designs are possible compared to kOr 120 in the mid-frequency range up to 20-30 kHz, and for high current CMCs

- Size and shape adjustable to space limitations

kOr 156

kOr 156 products are made of an iron-based amorphous material which has been developed as a contemporary replacement for electrical steel. Low losses compared with steel make components highly efficient in both purchasing and operational costs for low-frequency applications, and even mid-frequency applications as cut cores. We offer standard cut cores and a broad variety of customised shapes and finishings.

Features

- Low losses compared with silicon steel

- High BS (1,56 T), good linearity and frequency characteristics

- Effective permeability (hence: AL) and DC-tolerance adjustable with gaps

Benefits

- Applicable ideally for transformers

- Standard size cut cores match perfectly to standard bobbins

- Size and shape adjustable to space limitations

kOr 170

kOr 170 is the latest development result to maximise flux density of nanocrystalline material towards electrical steel, but reduce losses even compared to the common alternative for steel, kOr 156. Losses are in between kOr 120 / kOr 140 and kOr 156, and permeability is at a reliable level up to 100 kHz, which makes the material the perfect choice for power applications at 1 - 8 kHz. We started our offer with toroids in a plastic case. Magnetostriction is lower than for kOr 156 which also allows usage of impregnated cores.

Features

- Highest flux density for amorphous and nanocrystalline materials

- Best loss level for high-Bs materials

- Initial permeability around 10.000; at 100 kHz: 6000

- Reliable magnetostriction (15 ppm)

Benefits

- Smallest designs possible for power applications at about 1 - 8 kHz

- Reliable permeability up to high frequencies

- Customised shape and size

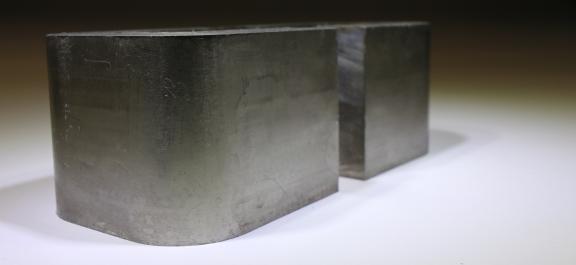

Customised shapes, cuts and dimensions

Amorphous and nanocrystalline cores are wound from ribbon (thickness about 20µm, width up to 50mm). Therefore we can offer many possibilities for customisation without significant tooling costs:

- Any size and shape what can be wound onto a solid body. Bars and other parts can be cut off wound cores. Complicated or oversized shapes can be assembled from different parts.

- Cores can be impregnated with epoxy for mechanical stability, especially before cutting.

- Cores are to be protected by boxing into plastic or metallic cases, epoxy coating, wrapping with fibre tape, and/or lacquer.

Within the Magnetics Products Technology Centre, we offer an array of services to help create customised solutions.

With the largest team of technical support specialists in Europe, we are at the forefront of a design led approach to delivering challenging and custom solutions for magnetic cores or components for production.

Whether your need is simple or complex, we can develop a solution to achieve your goals. With in- house experts we can design, develop and test prototypes that meet performance and environmental requirements of your application.

Technical news and insights

Access industry news and Acal BFi articles, white papers and brochures

Enquire

Submit your enquiry directly to one of our Technical Sales Specialists.

Alternatively call our Sales Team.

Mandatory fields*

Our approach

When it comes to developing custom solutions for tomorrow's technologies, we trust our approach to deliver the best possible outcome.

Our engineers will skilfully guide you through each stage of your project, working with you to understand and identify a solution that meets your technical and commercial needs before designing and integrating your solution.

Italy

Italy