Nanoperm Nanocrystalline Cores

- Technology

- Nanocrystalline cores

- Partner

- Magnetec

Nanocrystalline cores are indispensable for EMI applications, mainly for common-mode chokes (CMC), for high nominal and unbalanced currents. Magnetec offers a unique combination of Nanoperm cores to reduce motor bearing currents in inverter-motor systems (up to 1200 kW) with long cables.

The CoolBlue line has been specially designed to be used like a CMC (also called inductive absorber) where all phases of the motor cable or bus bars are pulled through the core. NaLA cores reduce high-frequency noise further when added over each single phase. Since usually no winding is applied, installation or retrofit are easy (stack as many cores as necessary for noise reduction) and save maintenance and replacement costs.

Range features

A high level overview of what this range offers

- Cores easy to install (cables or wires, bus bars pulled through) in inverter-motor systems

- CoolBlue: medium permeability of 30.000 to ensure high saturation currents when used as CMC; available as toroids and oval cores

- NaLA: high permeability 60.000 – 90.000 for high impedance; available as toroids

- Designed for cable lengths up to several hundred metres and motor power up to 1200kW

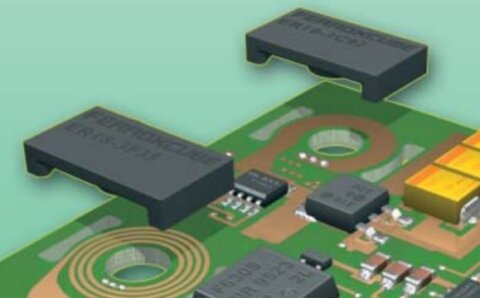

- Cores in plastic cases for operational temperature up to 130°C

- Oval shapes available

EMC cores based on nanocrystalline Nanoperm® material

| Nom dimensions | µr~ca. | Isat (A) | min (Al) @10KHz (µH) | Lfe (cm) | Afe (cm2) |

|---|---|---|---|---|---|

16 x 10 x 6 | 1K – 90K | 32 – 0.4 | 0.28 – 30 | 4 | 0.125 |

20 x 12 x 8 | 1K – 90K | 40 – 0.5 | 0.39 – 33 | 5.11 | 0.24 |

25 x 20 x 10 | 1K – 90K | 56 – 0.6 | 0.24 – 22.5 | 7.04 | 0.19 |

25 x 16 x 10 | 1K – 90K | 50 – 0.6 | 0.47 – 43 | 6.33 | 0.35 |

30 x 20 x 10 | 1K – 90K | 62 – 0.7 | 0.43 – 40 | 7.75 | 0.38 |

40 x 32 x 15 | 1K – 90K | 90 – 1 | 0.335 – 33 | 11.26 | 0.47 |

40 x 25 x 15 | 1K – 90K | 80 – 0.9 | 0.74 – 76 | 10.03 | 0.8 |

45 x 30 x 20 | 1K – 90K | 92 – 1 | 0.9 – 75 | 11.6 | 1.2 |

50 x 40 x 20 | 1K – 90K | 112 – 1.2 | 0.47 – 40 | 13.9 | 0.73 |

50 x 40 x 25 | 1K – 60K | 112 – 2 | 0.58 – 34.4 | 14.08 | 0.91 |

63 x 50 x 30 | 1K – 60K | 140 – 2.5 | 0.81 – 43.7 | 17.67 | 1.44 – 1.60 |

80 x 63 x 30 | 1K – 60K | 180 – 3 | 0.75 – 45.8 | 22.36 | 1.86 |

100 x 80 x 30 | 1K – 60K | 220 – 4 | 0.70 – 42.4 | 28.16 | 2.25 |

130 x 100 x 30 | 1K – 60K | 290 – 5 | 0.82 – 48 | 35.92 | 3.33 |

160 x 130 x 30 | 1K – 60K | 362 – 6 | 0.68 – 37.7 | 44.98 | 3.5 |

200 x 175 x 30 | 1K – 60K | 470 – 8 | 0.41 – 24.9 | 58.82 | 2.74 |

300 x 250 x 30 | 1K – 60K | 688 – 11 | 0.56 – 28.6 | 86.4 | 4.7 |

CoolBlue tape wound cores to reduce motor bearing currents

| Types | Nom dimensions | Al @10KHz | Al@100KHz | Le | Afe | |

|---|---|---|---|---|---|---|

Toroidal | 30 x 20 x 10 – 500 x 450 x 30 | 13.6/27.2 – 8.0/20.0 | >6.70 – 7.20 | 7.8 – 149.1 | 0.36 – 5.60 | 2.0 – 40 |

Oval | 50 x 40 x 20 – 300 x 254 x 30 | 12.6/28.4 – 15.8/31.5 | >6.30 – >7.90 | 14.1 – 87.1 | 0.8 – 5.20 | 3.5 – 23 |

Toroidal | 16 x 11 x 5 – 160 x 130 x 30 | 18.4/36.8 – 37.7/75.3 | >4.6 – >13 | 4.14 – 45.39 | 0.1 – 3.24 | – |