Ferrites for power conversion

- Technology

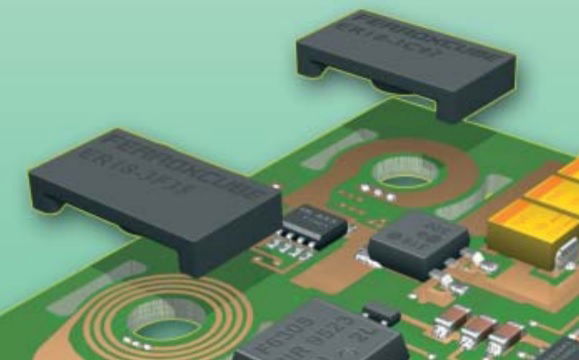

- Ferrite cores

- Partner

- Ferroxcube

Ferroxcube differentiates ferrite materials within power conversion according to the operational frequencies, with a threshold around 300KHz, creating two different groups of materials (3Cxx and 3Fxx).

Working temperature, flux, efficiency, and frequency are key parameters when selecting the correct material. Ferrites in this range are made of 2 alloys.Manganese zinc oxide (MnZn) resulting in a very low-cost solution and nickel-zinc (NiZn) based at a slightly higher cost due to the nickel.

Shapes that typically are used in this application are E, ER, EFD, EQ, PQ, RM, U, and planar E and ER.

Material names in this range start with 3Cx, examples are 3C96 and 3C98 minimising power losses; 3C95 and 3C97 working in a wide temperature range; 3C92 and 3C99 offering a high Bsat.

Material starting with 3Fx, examples are 3F36 and 3F46 covering a range of frequency up to 3MHz; or with 4Fx like 4F1, working in a wider range of frequency up to 15MHz.

Range features

A high level overview of what this range offers

- Low cost materials (MnZn) and medium-cost NiZn materials

- Four development trends:- Wide temperature: 3C95F and 3C97- Low power losses 3C91A and 3C98- High saturation flux density (Bsat) 3C99 and 3C92A- Increase working frequency by reducing power losses

- Available shapes: E, planar E, EC, EFD, EP, ETD, ER, planar ER, U, RM, PM, PQ, and gapped toroids

- Frequencies < 300KHz

- 3C99 high Bsat – optimised to work at 200°C

- 3C95F – wide working temperature range (25°C – 100°C)

- 3C98 – lower losses at 100°C

- 3F36 – standard to reach 600KHz, flat losses 25°C – 100°C

- 3F46 – standard to reach 1MHz

- 4F1 – standard working good up to 10MHz

What’s in this range?

All the variants in the range and a comparison of what they offer

Low frequency materials

| Material | µi at 25°C | Bsat (mT) at 25°C | Tc (°C) | Pv (100°C 100KHz 200mT) KW/m3 | Notes |

|---|---|---|---|---|---|

3C90 | 2300 | 470 |

| 450 | Min loss @100°C |

3C91 | 3000 | 470 |

| 300 (@ 60°C) | Min loss @60°C |

3C94 | 2300 | 470 |

| 350 | Min loss @100°C |

3C92 | 1500 | 520 |

| 350 | High Bsat |

3C92A | 1800 | 570 |

| 300 | High Bsat |

3C95 | 3000 | 530 |

| 290 | Flat loss @ 25-100°C |

3C95A | 3300 | 550 |

| 290 | Wide temperature |

3C95F | 3000 | 550 |

| 250 (@ 125mT) | Tide temperature |

3C97 | 3000 | 530 |

| 320 | Flat loss @ 60 – 140 °C |

3C96 | 2000 | 500 |

| 300 | Min loss @ 100°C |

3C98 | 2500 | 530 |

| 250 | Min loss @ 100°C |

3C99 | 800 | 500 |

| 140 | Optimised for 200°C working temperature |

High frequency materials

| Material | µi at 25°C | Bsat (mT) at 25°C | Tc (°C) | Pv(100°C 100KHz 200mT) KW/m3 | Notes |

|---|---|---|---|---|---|

4F1 | 80 | 320 |

| 200 (100°C 10MHz 5mT) | Frequency < 15MHz |

3F3 | 2000 | 440 |

| 150 (100°C 400KHz 50mT) | Optimal frequency ≤ 400kHz |

3F36 | 1600 | 520 |

| 700 (100°C 500KHz 100mT) | Optimal frequency < 600kHz, flat power loss 25 – 100°C |

3F46 | 750 | 520 |

| 50 (100°C 3MHz 10mT) | Optimal frequency 1 – 3MHz |