Customised High-Frequency (HF) Power Transformers

- Technology

- Switch-mode transformers

- Partner

- Acal BFi

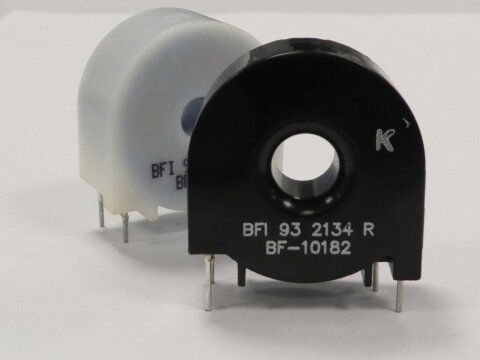

The Magnetic Products Technology Centre develops customised transformers based on ferrite cores or nanocrystalline cores from our Acal BFi kOr brand. These customised high frequency transformers are engineered for designers who need tightly specified magnetic components rather than standard catalogue parts. Each transformer is designed around ferrite or nanocrystalline cores selected to suit the target frequency, power level and efficiency requirements.

Electrical parameters, insulation levels, environmental conditions and installation constraints such as available space, mounting and connection style are all taken into account from the start of the project. Thermal design, including air cooling or integration to heat sinks, is considered alongside the electrical design to ensure reliable operation over the full temperature range.

Budget and expected production volume are included in the design brief so that the result is not only technically optimised but also commercially viable, even for low or medium quantities. Typical applications include mechanical engineering, on-board chargers and charging stations for electric vehicles, railway systems and uninterruptible power supplies, where high efficiency, safety and long-term reliability are critical.

Range features

A high level overview of what this range offers

-

Power range 1 W – 100 kW – supports everything from low-power auxiliary supplies to high-power converters in industrial and transport systems

-

Compact designs with optimum core material and size, and reduced copper usage – tailored for frequencies from few kHz to 200 kHz

-

Insulation voltage up to 16 kV – suitable for applications with demanding isolation and safety requirements

-

Operational temperature up to 155 °C – supports operation in harsh environments and thermally constrained installations

-

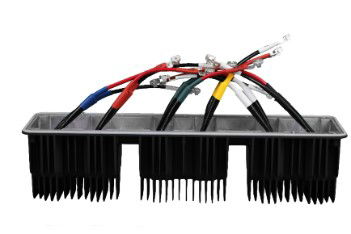

Open design, plastic or metal housing – gives flexibility to match mechanical, safety and EMC requirements

-

Air cooling or heat sink connection – allows integration with existing cooling concepts for improved reliability and lifetime

-

Available for all common transformer topologies – supports a wide range of converter architectures without compromising on performance

-

Low noise in audible range by careful core selection and winding design

FAQs

for Customised High-Frequency (HF) Power Transformers

The transformers can be designed for power levels from as low as 1 W up to 100 kW, ranging from auxiliary supplies to high-power conversion stages.

Designs are based on ferrite or nanocrystalline cores of our brand Acal BFi kOr, with the material chosen to match the required frequency range, power density, efficiency and loss behaviour of the target application.

Yes, the insulation system is defined according to the required isolation voltage, creepage and clearance distances, and can be configured for insulation voltages up to 16 kV to support demanding safety concepts.

The transformers can be designed for operation up to 155 °C, taking into account the specified ambient temperature, cooling method and hotspot limits within the winding and core.

Yes, the transformers can be supplied as open designs or integrated into plastic or metal housings, enabling integration into existing mechanical layouts and helping to meet safety and EMC requirements.

Cooling concepts can be based on natural or forced air flow, and the transformer can be prepared for direct heat sink mounting where required, ensuring stable operation and longer service life.

The design approach covers all common transformer-based topologies used in modern power electronics, including both isolated DC-DC and AC-DC converter architectures. So, our customised magnetic component can be matched precisely to the chosen circuit.

Yes, they are well suited to on-board chargers and stationary charging stations, where high efficiency, robust isolation and compact dimensions are essential.

Transformers can be tailored to the electrical, mechanical and environmental demands of railway and UPS applications, including high reliability, robust insulation and operation under challenging temperature and vibration conditions.

The design process involves close cooperation between magnetic design engineers and the customer’s development team. Prototypes can be produced in our Magnetic Products Technology Centre quickly within days once the key electrical, mechanical and environmental parameters have been defined.