Harsh Environment Fibre Optic Assemblies

- Technology

- Fibre optic cables, connectors and assemblies

- Partner

- Acal BFi

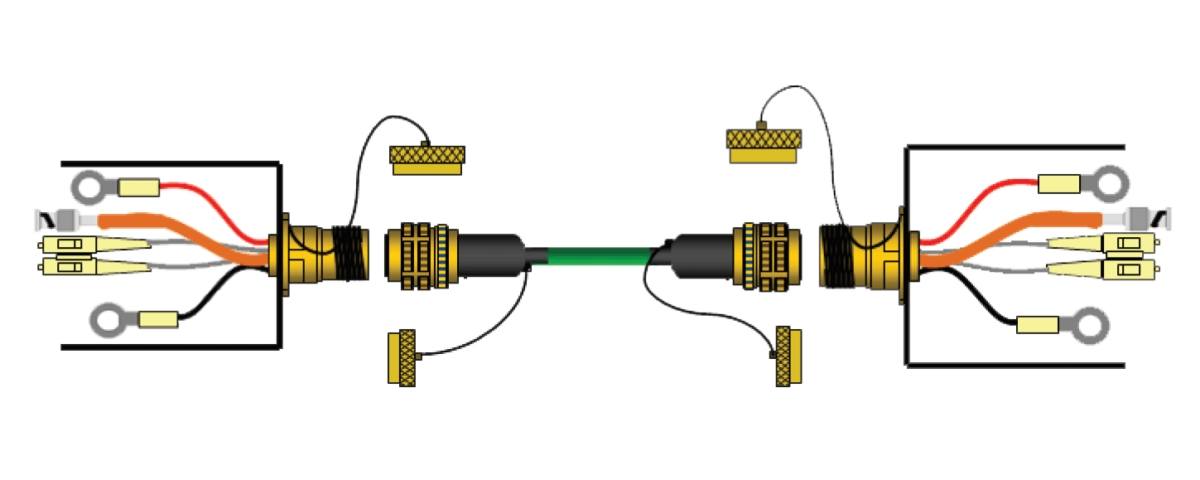

Acal BFi offer a unique fibre optic / hybrid fibre optic and copper cable assembly service for commercial, industrial and harsh environments.

We have over 20 years’ experience in the design and manufacture of both fibre only and hybrid fibre / copper cables. We have designed, produced, and installed cable assemblies for many diverse environments, including nuclear submarines, oil exploration vessels, trains, open cast mines and roadside traffic gantries. Although all very different, the one thing all of these applications have in common is the need for a tailor-made solution capable of operating in a harsh environment with the need for strict quality standards. With an in-house, purpose-built, ISO9001-accredited, custom-assembly centre, we have the resources and expertise to provide a solution to meet your needs.

Range features

A high level overview of what this range offers

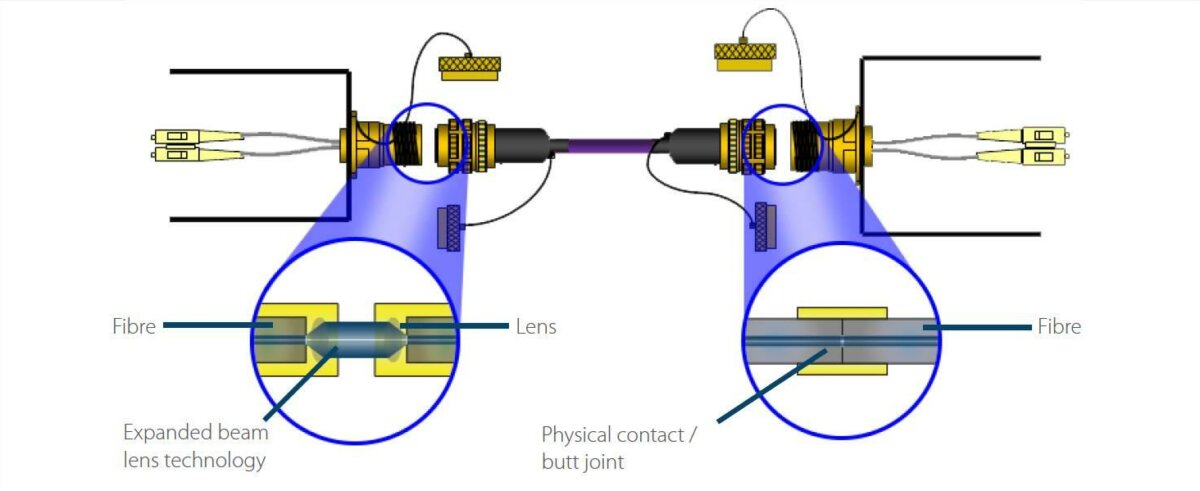

- Physical contact / butt-joint technology- single channel to 72 channels

- Expanded beam technology- single channel to 4 channels

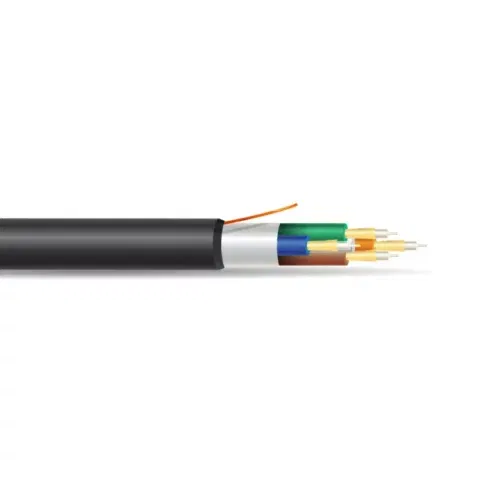

- Hybrid custom cable assemblies- bespoke to meet application requirements

- Circular MIL-DTL-38999 connector option with multiple planforms utilising size 16, MIL-29504 fibre optic termini

- Hermaphroditic options

- Numerous connector plating options including ARCAP, Black Zinc Nickel, stainless steel and marine aluminium bronze

- ATEX approved termination facility for oil & gas applications

- Cable options including MIL Tactical cable with / without armoured cladding, patch cords and conduit services

- On-site termination facility

- Assemblies produced at our UK based in-house manufacturing centre alongside our dedicated MIL connector assembly line

Ruggedised / harsh environment fibre assemblies

Ruggedised / harsh environment hybrid fibre / copper assemblies