RS6780 Scientific MWIR Camera

- Technology

- Infrared R&D cameras

- Partner

- Teledyne FLIR

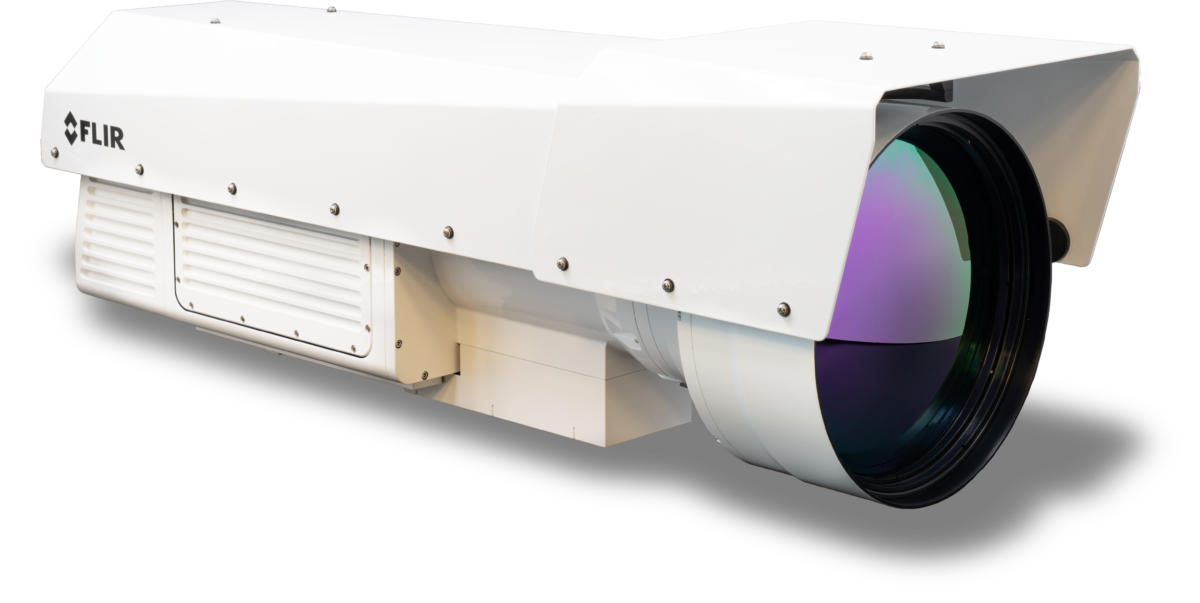

The FLIR RS6780 Scientific MWIR Camera is a specialised thermal imaging system built for researchers and engineers who need precision at long range. This camera pairs a 640 × 512 mid-wave infrared sensor with advanced optics and controls, making it ideal for the most demanding R&D applications.

It features a motorised 50–250 mm continuous zoom lens (expandable to 150–750 mm with an optional extender), so users can capture both wide-area views and distant targets without swapping optics.

The RS6780 is a radiometric camera, meaning it provides accurate temperature data for every pixel – useful for scientific analysis of high-temperature events or material testing. With advanced triggering and synchronisation capabilities (including precise timestamping of frames), it easily integrates into complex test setups and captures critical moments in experiments. Its durable, weatherproof design (IP65-rated) allows the RS6780 to be deployed indoors or out, from laboratory settings to open-air test ranges.

The camera supports full-frame capture up to 125 Hz and even higher frame rates with small window sizes (reaching into the thousands of frames per second for rapid events), ensuring you never miss fast transient phenomena. In short, the FLIR RS6780 delivers the flexibility, accuracy, and robustness required for applications like aerospace research, defence range tests, high-speed thermal analysis, and other scientific investigations.

Range features

A high level overview of what this range offers

- High-resolution cooled detector – Equipped with a 640 × 512 indium antimonide (InSb) MWIR sensor, the RS6780 captures crisp thermal images with excellent sensitivity. This high resolution allows for fine detail and accurate temperature readings, even for fast-moving or distant targets.

- Motorised 3-position filter wheel – The built-in filter wheel can automatically insert neutral density (ND) filters, enabling measurements of extremely hot objects without saturation. With the optional filters, the camera can accurately measure temperatures up to +3000 °C, expanding its usability for combustion experiments, jet engine tests, and other high-temperature applications.

- Continuous zoom optics – The 50–250 mm continuous metric zoom lens provides a smooth transition from wide field-of-view to telephoto observation. This flexibility means you can frame a scene optimally or track an object as it moves closer or further away, all without interrupting the test to change lenses. Each frame is also stamped with the exact zoom position (focal length), ensuring precise scaling and analysis – a key advantage for quantitative research and TSPI (Time/Space Position Information) data collection.

- Advanced synchronisation & triggering – The RS6780 is designed to work in tandem with other instruments and events. It offers multiple trigger and sync modes (including Sync In/Out, IRIG timecode, and lock-in) to precisely control when an image frame is captured. You can synchronise the camera with external sensors or events – for example, triggering a frame at the exact moment of a detonation or component failure – and every image is timestamped with high accuracy. This level of control and timing guarantees reliable data correlation in complex experiments or field tests.

- Rugged, field-ready design – Housed in a robust IP65-rated enclosure, this camera is protected against dust and water jets, so it’s well-suited to outdoor ranges and harsh industrial environments. The system’s architecture is relatively lightweight (around 12.7 kg without the optional extender lens) and includes standard mounting points, making it straightforward to set up on tripods, tracking mounts, or fixed installations. Whether used in a lab or on a remote test range, the RS6780 reliably withstands tough conditions and maintains calibration stability over its operating temperature range of -20 °C to 50 °C.

- Radiometric output & connectivity – The FLIR RS6780 provides fully calibrated temperature data for every pixel, which can be streamed in real time via Gigabit Ethernet (GigE Vision) or CoaXPress interfaces. Researchers can record thermal data directly to a PC or data acquisition system for analysis. The camera also includes a standard HD-SDI video output for live monitoring on external displays, and supports remote control protocols (GenICam over GigE/CXP and RS-232 serial control) for seamless integration into automated test setups. These connectivity options mean the camera can both deliver live imagery and log quantitative datasets simultaneously, fitting into a wide range of experimental workflows.

Downloads

for RS6780 Scientific MWIR Camera

What’s in this range?

All the variants in the range and a comparison of what they offer

| Imaging & Optical | Value |

|---|---|

Resolution (Sensor Array) | 640 × 512 pixels |

Detector Type | Cooled InSb (Indium Antimonide) |

Detector Pitch | 15 µm |

Spectral Range | 3.0 – 5.0 µm (mid-wave infrared) |

Thermal Sensitivity (NETD) | ~27 mK (at typical settings) |

Camera f-number | f/4.0 |

Focus | Motorised focus, adjustable field of view (with zoom) |

Lens (Standard) | 50–250 mm continuous metric zoom, low-latency metadata output |

Optional Lens Attachment | 3× afocal extender (increases focal length to 150–750 mm) |

Digital Zoom | 1× or auto-fit (digital), optional on/off |

Frame Rate (Full Frame) | Programmable from 0.0015 Hz up to 125 Hz |

Subwindow (Windowing Mode) | Flexible window sizes down to 16 × 4 pixels (in 16×4 increments), allowing higher frame rates (up to ~4,000 fps with minimal window) |

Readout Modes | Asynchronous integrate-while-read or integrate-then-read (snapshot mode) |

Sensor Cooling | Closed-cycle rotary cooler (maintains sensor at cryogenic temperature) |

On-camera Storage | None (streaming output only) |

Image/Video Output | HD-SDI (analog/digital video out) |

| Measurement & Analysis | Value |

|---|---|

Radiometric Calibration | Factory calibrated for temperature measurement |

Standard Temperature Range | 0 °C to +350 °C (calibrated without filters) |

Optional High-Temp Range | Up to +3000 °C (with calibrated ND filters installed) |

Accuracy (Thermometric) | ±2 °C or ±2% of reading (whichever is greater) for >100 °C (±1 °C/±1% typical) |

Calibration Drift Compensation | Yes (ambient temperature drift compensation with factory calibration) |

Automatic Gain Control | Modes: Manual, Linear, Plateau Equalization, DDE (Digital Detail Enhancement) |

Image Timestamping | Precision internal clock; supports IRIG-B timecode for absolute timestamp (TSPI-accurate frame timing) |

| Synchronisation & Triggering | Value |

|---|---|

Sync Modes | Sync In, Sync Out, Tri-Level Sync (for frame sync with external sources) |

Trigger Modes | External Trigger-In (capture on trigger), Software trigger, or header-based triggering |

IRIG Timecode | Yes – decode and embed IRIG-B (AM) for synchronisation with timing systems |

Lock-In Input | Supported (for synchronising integration to a reference signal) |

| Communication & Control | Value |

|---|---|

Primary Data Interface | Gigabit Ethernet (GigE Vision compliant) |

Alternate Data Interface | CoaXPress single-link (v1.1) |

Command & Control Protocols | GenICam (over GigE or CXP), RS-232 serial |

Onboard Overlay | Customisable on-screen display (can be toggled on/off in output) |

Palette Options | Selectable 8-bit colour palettes for video output |

| Physical & Environmental | Value |

|---|---|

Enclosure Rating | IP65 (dust-tight, protected against water jets) |

Dimensions (L × W × H) | Main body: 544 mm × 177.8 mm × 213.9 mm (without extender) |

(With 3× extender attached) | (Approximately 726.4 mm × 243.4 mm × 240.7 mm) |

Weight | ~12.7 kg (standard configuration without 3× lens), ~16.8 kg (with 3× lens attached) |

Mounting Provisions | 5 × 1/4″-20 UNC threaded mounting holes; 2 × 3/8″-16 UNC mounting holes (on base) |

Power Supply | 24 V DC input, < 24 W power draw (steady state) |

Operating Temperature | -20 °C to +50 °C (ambient) |

Storage Temperature | (Not specified on page; typically similar range or broader) |

External Finish | Weatherproof, durable coating suitable for outdoor use |

Compliance | Designed for export-controlled applications (ITAR/EAR may apply) |

The FLIR RS6780 thermal camera is shown with its standard 50–250 mm continuous zoom lens attached. This front-angle product image highlights the camera’s robust housing and large optic, illustrating its design for long-range, high-precision thermal imaging in research applications.

FAQs

for RS6780 Scientific MWIR Camera

The RS6780 is built around a cooled indium antimonide (InSb) mid-wave infrared detector. This sensor has a resolution of 640 × 512 pixels. Because the detector is cryogenically cooled, it offers very high sensitivity and can detect small temperature differences that an uncooled sensor might miss. The mid-wave IR band (3–5 µm) is ideal for capturing high-temperature phenomena and provides clear thermal detail at long ranges, which is essential for scientific and aerospace applications.

Yes. The FLIR RS6780 is explicitly designed to handle very high temperature targets. It includes a motorised 3-position filter wheel that can deploy special neutral density (ND) filters in front of the sensor. These filters reduce the infrared energy reaching the detector, allowing the camera to measure temperatures up to ≈3000 °C (when the appropriate filter and calibration are used) without saturating the image. In its standard configuration (no filter), the camera is typically calibrated for a range of 0 °C to 350 °C, but with high-temperature filters engaged, it can accurately capture scenes like engine exhaust plumes, explosions, or molten metal processes. This flexibility means researchers can use the RS6780 for both moderate and extremely high-temperature experiments by simply switching filters as needed.

The continuous metric zoom lens (50–250 mm) on the RS6780 provides a huge benefit in terms of flexibility and convenience. Instead of swapping out fixed focal length lenses (and potentially refocusing or recalibrating each time), the user can smoothly zoom in or out to frame the scene optimally. For example, you might start with a wide view to locate your subject, then zoom in to capture fine details or small targets at a distance – all in one continuous sequence.

Importantly, this lens is a metric zoom, meaning the camera knows the exact focal length at every zoom position and encodes that information with each frame. The advantage is that any measurement or spatial calculation (such as determining object size or applying temperature calibration) remains accurate throughout the zoom range. In practical terms, the continuous zoom saves time and preserves data integrity, enabling dynamic tracking of moving objects or tests where the distance to the subject changes. Moreover, with the optional 3× extender lens attached, the zoom range extends up to 750 mm, allowing the camera to focus on objects incredibly far away while still maintaining sharp focus and measurement accuracy.

The camera includes sophisticated sync and trigger features to coordinate with external systems. It offers a Trigger-In input that allows an external device (like a timing system, sensor, or test controller) to trigger the camera’s frame capture at a precise moment. For example, you could have the camera take an image exactly when a spark is initiated or when a projectile passes a certain point. There are also Sync-Out signals, so the camera can generate a pulse to inform other instruments when it has captured a frame – useful if you want other devices to log data at the same instants as the images. Additionally, the RS6780 supports IRIG-B timecode, a common timing signal in test ranges. The camera can decode IRIG-B (or accept GPS timing via IRIG) and use it to timestamp each frame with an accurate time-of-day, which is crucial for Time–Space–Position Information (TSPI) in range tracking applications. It even has modes like tri-level sync and lock-in for specialised synchronisation needs. In summary, the RS6780 can both listen and talk in terms of timing – it can be a slave to an external trigger or act as a master sync source – ensuring that it integrates seamlessly into complex experimental setups where precise timing is everything.

Absolutely. The camera is built into a sturdy housing with an IP65 rating, which means it’s dust-tight and protected against low-pressure water jets from any direction. In practice, this translates to reliable operation in outdoor environments – the camera can handle wind-blown dust, light rain, and general weather exposure without issue. It’s designed for use on open-air test ranges (for example, military proving grounds or rocket test stands), so it can cope with things like shock, vibration, and wide temperature swings. The specified operating temperature range is -20 °C to 50 °C, covering most environmental conditions you’d encounter (from cold morning tests to hot desert afternoons). With a weight of about 12–16 kg (depending on lens configuration), the RS6780 is portable enough to move between sites or mount on tracking pedestals, but it’s also heavy-duty enough to remain stable during use. It has multiple standard mounting threads on its base, making it easy to secure to tripods, vehicle mounts, or fixed platforms. In short, the RS6780’s construction and environmental specs ensure it will perform reliably whether you’re in a controlled lab or out in the field.

The RS6780 offers a rich set of interfaces for both live video and data. For direct live viewing, it has a standard HD-SDI video output, which you can connect to a monitor or recorder to see the thermal footage in real time (common formats like 720p/1080p or even analog SD video are supported). For scientific data collection, the camera provides a Gigabit Ethernet port – it’s GigE Vision compatible, meaning you can stream the full radiometric image data to a computer at high speed. This is useful for capturing sequences of images for post-analysis or real-time processing on a PC. It also supports CoaXPress (a single-link CXP output), which is another high-bandwidth digital interface often used in industrial imaging; either interface can be used to integrate with custom software or third-party imaging platforms under the GenICam protocol. In addition, the camera has an RS-232 serial port for simple remote control or status monitoring. Through these interfaces, you can adjust settings, initiate captures, or log data. The flexibility of multiple outputs ensures that the RS6780 can slot into existing data acquisition systems – whether you need raw thermal data for every frame or just a composite video feed for a security DVR, this camera has you covered. And because the data is radiometric, when you use the Ethernet/CXP streaming, you’re getting actual temperature readings that you can analyse frame by frame.

It definitely provides calibrated temperature readings – the RS6780 is a radiometric thermal camera. That means each pixel in the thermal image can be translated to an accurate temperature value (given the object has the appropriate emissivity, etc.). When the camera leaves the factory, it comes with a standard calibration (usually for -20 °C to +350 °C as mentioned) for its supplied 50–250 mm lens, so you can point it at a scene and read actual temperatures right out of the box. Furthermore, FLIR offers factory calibrations for different temperature ranges or with optional lenses/filters – for instance, if you plan to measure very high temperatures using the ND filters, the camera can be calibrated for those extended ranges. All the temperature measurement algorithms (like compensation for ambient drift or lens transmission) are handled internally, so the user gets a straightforward temperature output. This capability is crucial for research: instead of just a pretty thermal image, you can quantitatively analyse how hot something is, how heat distributions change over time, or how fast an object is heating or cooling. In summary, the RS6780 isn’t just an imager – it’s a precise temperature measurement instrument, allowing advanced thermal analysis in R&D settings.

The FLIR RS6780 is aimed at high-end research and development applications – essentially anywhere you need detailed, reliable thermal data from challenging scenarios. Some typical use cases include:

- Aerospace and defence testing: The camera is often used on military test ranges to track and measure thermal signatures of missiles, aircraft, or explosions from a safe distance. Its long-range zoom and high-speed capture are ideal for these scenarios, as is the rugged design for outdoor use.

- Materials science and engineering: Researchers can use the RS6780 to study how materials behave under thermal stress – for example, observing heat distribution in a component during stress testing, or analysing the cooling rates of metals and composites. The radiometric output and high temperature range make it suitable for experiments like furnace testing or fire resistance studies.

- Automotive and electronics testing: In automotive R&D, the camera might capture the thermal footprint of engines, exhaust systems or brakes under load, while in electronics, it could track the heat generation of circuits or batteries during operation. The precise timing and triggering allow syncing with other test data (like engine telemetry or electrical measurements).

- Science and academia: Universities and labs conducting experiments in fields such as combustion research, energy systems, or environmental science can benefit from the camera’s ability to quantify temperature changes. For instance, it could be used in volcanic research to measure lava flow temperatures, or in solar energy research to evaluate the performance of thermal concentrators.

Essentially, any project that demands accurate thermal measurement over a distance, or of fast events, could find the RS6780 indispensable. Its combination of high resolution, flexibility in optics, and robust integration features means it excels in situations beyond the capabilities of standard thermal cameras. Users in these fields value the RS6780 for giving them deeper insight into thermal phenomena, ultimately helping drive innovation and safety improvements in their designs.