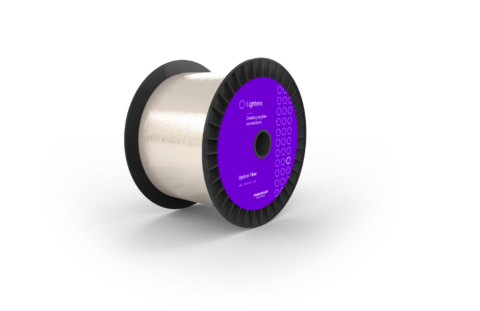

Rayleigh-Brillouin Optimised Fibres

- Technology

- Speciality fibre

- Partner

- Lightera (formerly OFS)

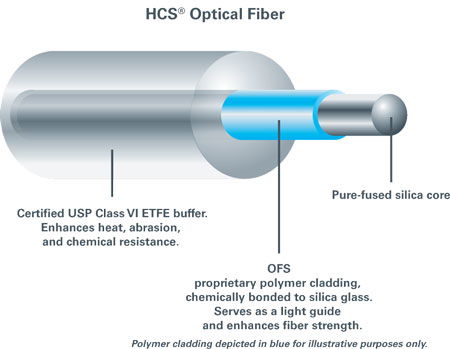

Optical fibres for sensing applications need to offer optimal performance and reliability in different harsh environment applications whilst ensuring the specific optical requirements for Distributed Acoustic Sensing (DAS) and/or Distributed Strain Sensing (DSS) are met fully without compromising installation locations or limiting operational distances.

Lightera (formerly OFS) has the experience and technologies in place to offer customised Fibre Bragg Grating (FBG) to support varying sensing demands.

By offering several materials that can be used as fibre coatings to protect them in challenging environmental conditions, Lightera (formerly OFS) can provide a custom engineered solution resistant to chemicals, high temperatures, oils, UV, and resilience in high-pressure environments.

Range features

A high level overview of what this range offers

- Temperature sensing: Oil wells and pipelines

- Strain sensing: Oil/Gas pipelines, civil structures (e.g. bridges), composite structures such as wind turbine blades and aircraft wings

- Acoustic sensing: Oil, gas, water pipelines and railroads

- Shape sensing: Medical instruments and composite structures

- AcoustiSens™ single mode fibres offer improved OSNR for great ASNR

- Pyrocoat® is offered as a polyimide coating with high temperature (-196 to 300 °C) performance in a small diameter fibre

- Silicone is the coating of choice where compression relief and resistance to chemicals are key necessary performance parameters

- A silicone/acrylate buffer is ideal for up to 160°C and can be easily stripped

- PEEK and PFA coatings are ideal where resistance to acids, salts and oils are necessary

Downloads

for Rayleigh-Brillouin Optimised Fibres