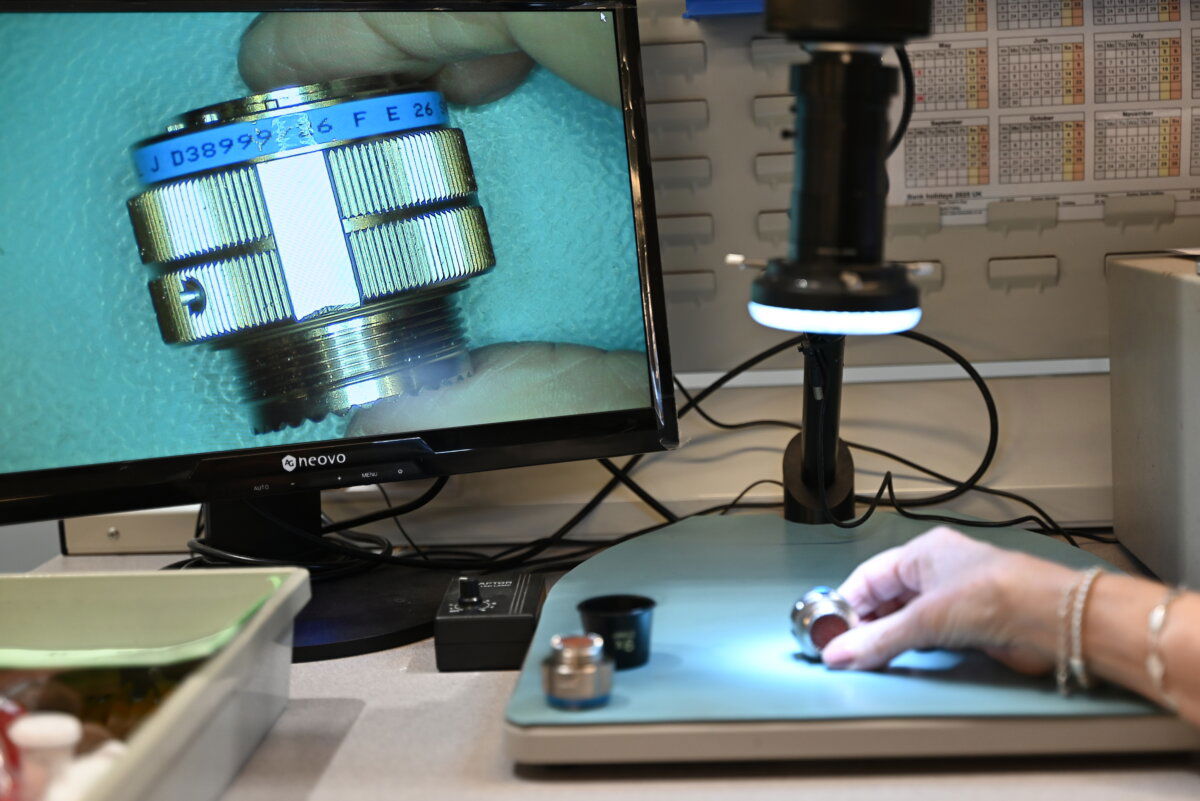

Our Interconnect and Cable Assembly Technology Centre continually designs and assembles custom interconnect solutions and cable assemblies to customers specifications.

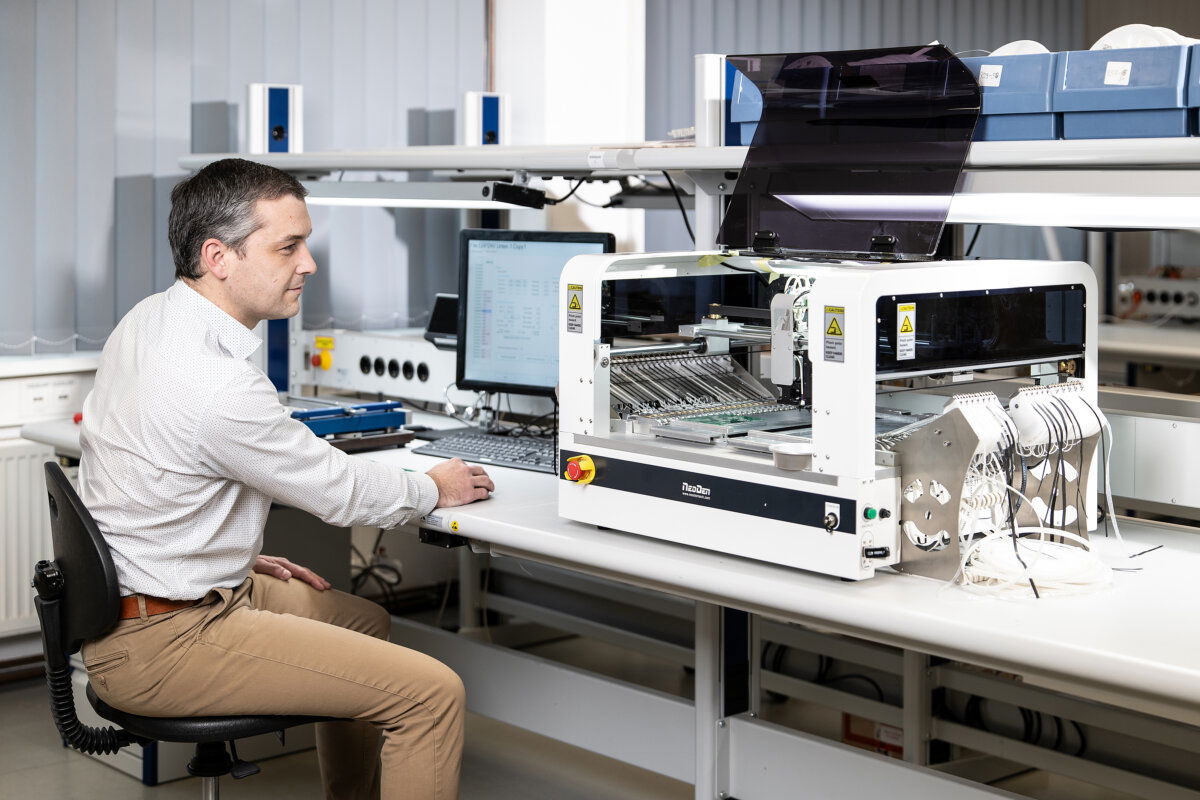

Acal BFi – Interconnect and Cable Assembly Technology Centre

Design-led interconnect and cable assembly solutions

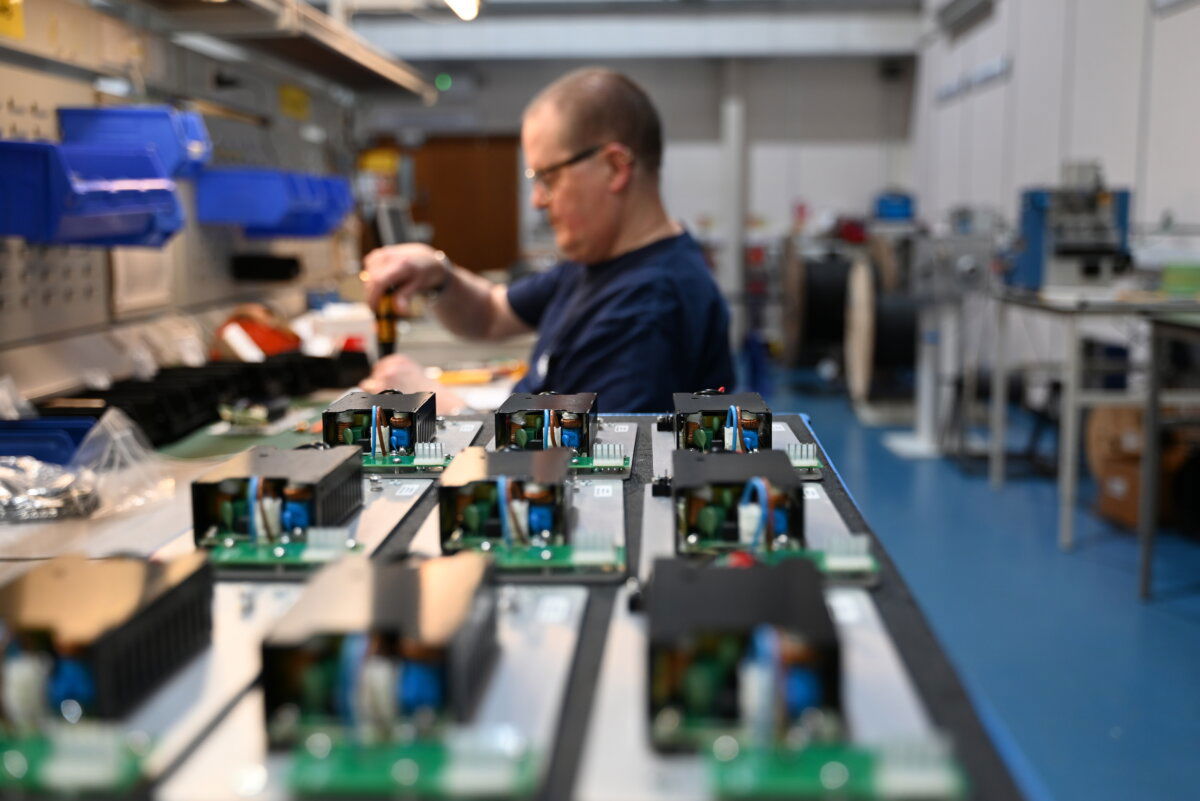

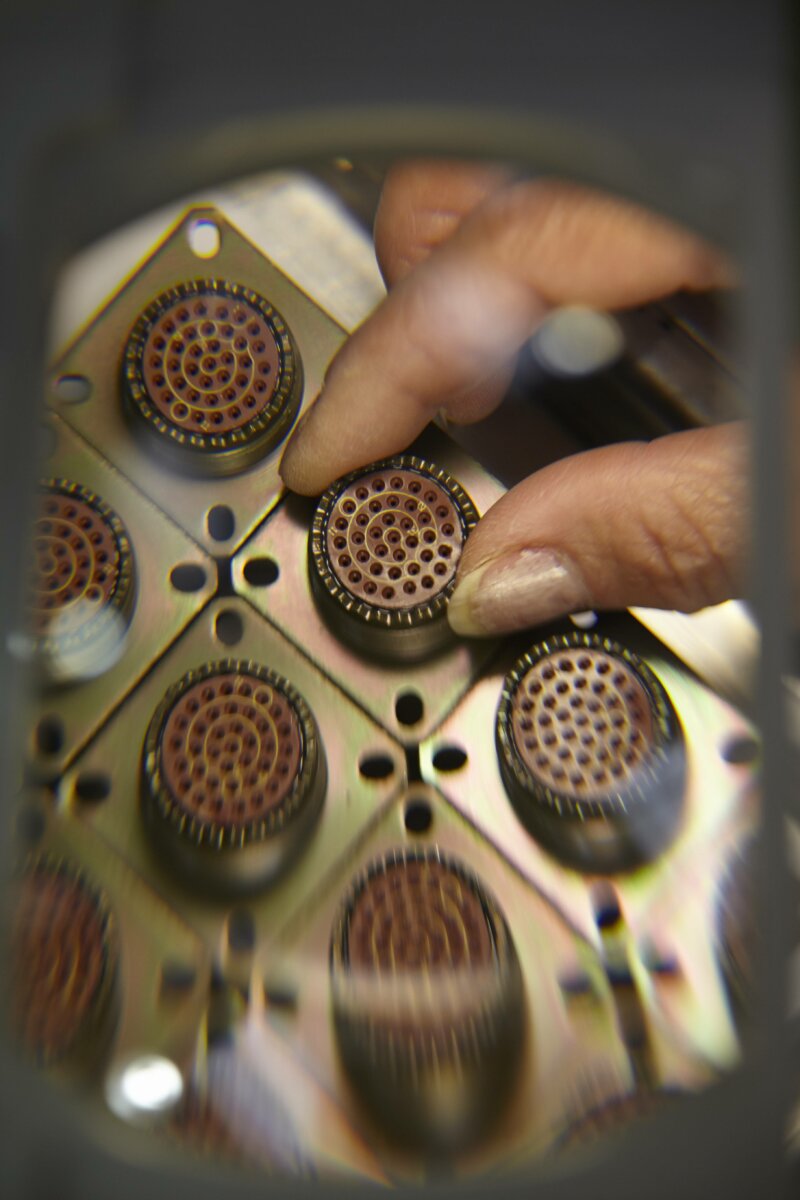

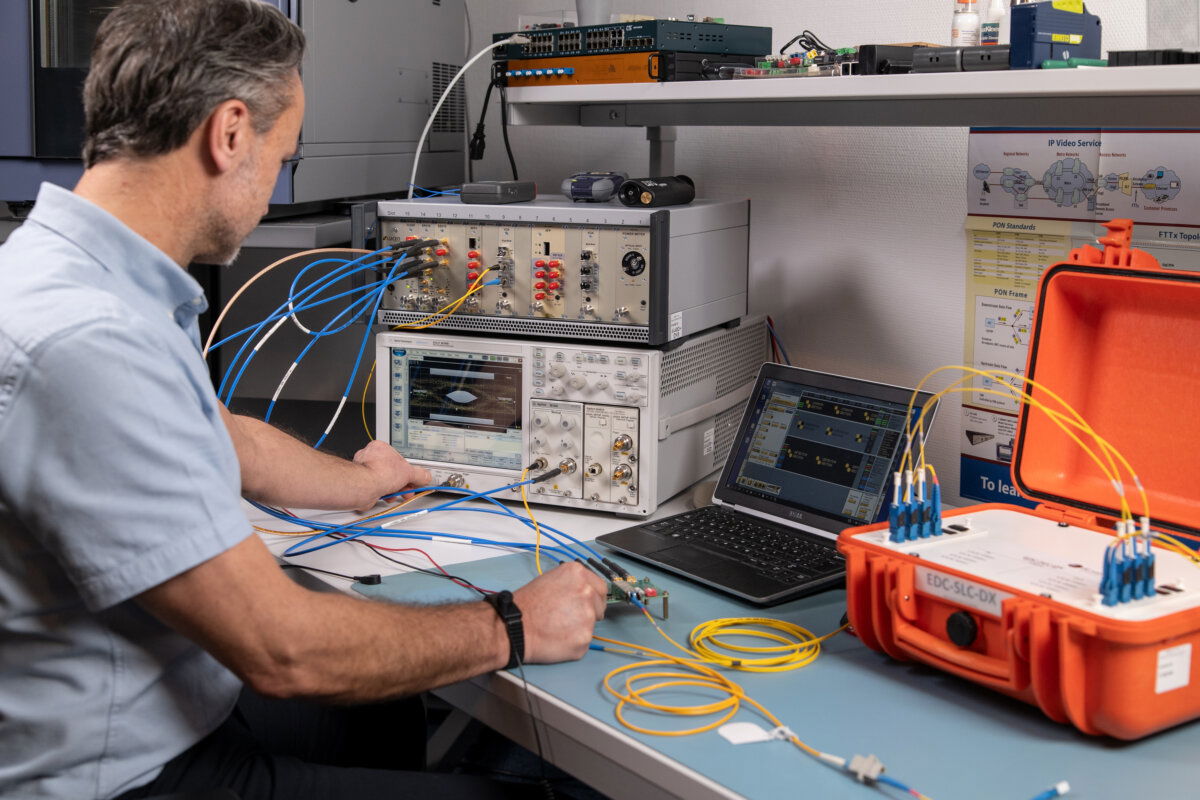

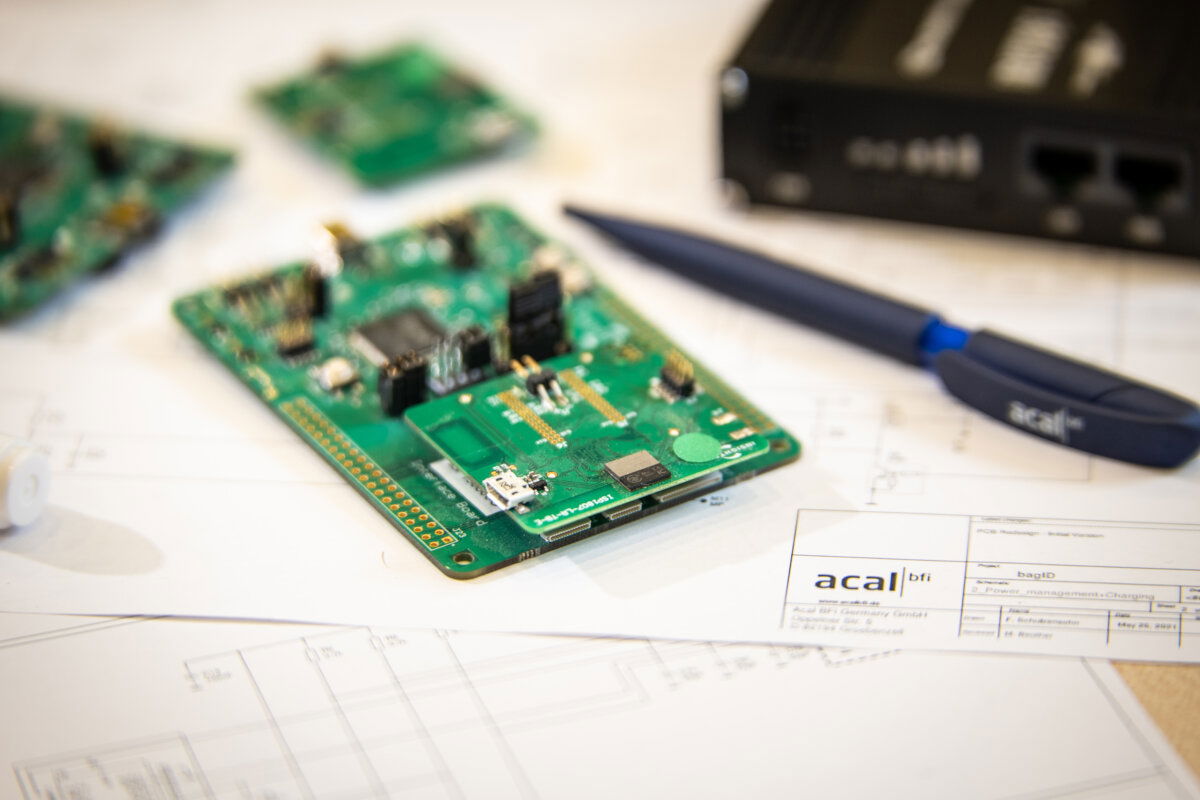

The Interconnect and Cable Assembly Technology Centre is Acal BFi’s dedicated hub for the design, manufacture, and integration of high-performance interconnect systems and cable assemblies for industrial, defence, aerospace, security, and harsh environment applications.

With over 50 years of experience and a UK-based, purpose-built production facility, we support customers with reliable interconnect solutions – from individual connector assemblies through to complex, fully engineered cable harnesses and fibre optic systems.

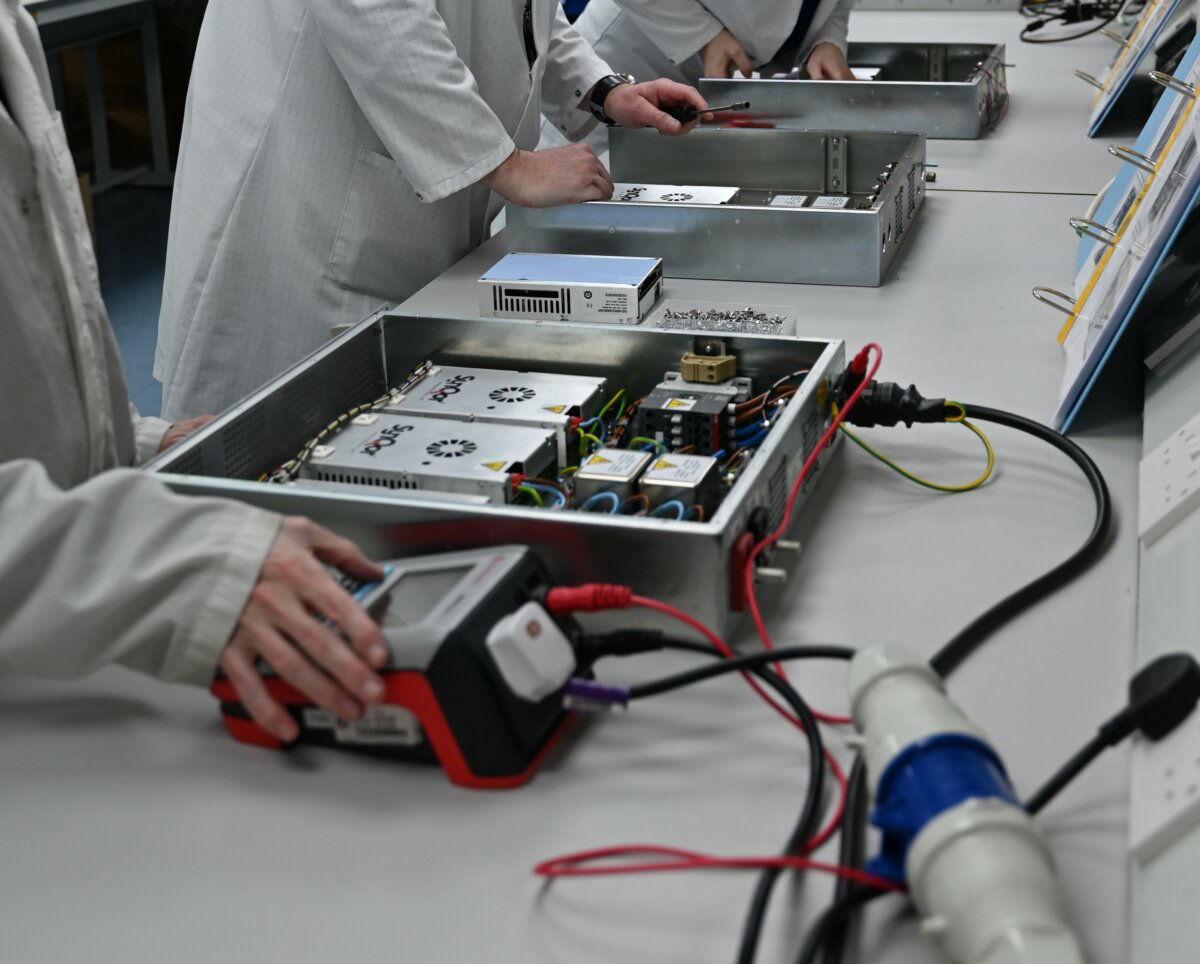

By combining deep industry expertise, long-standing manufacturer partnerships, and in-house assembly, testing, and integration capabilities, the Interconnect and Cable Assembly Technology Centre enables robust, compliant, and repeatable solutions that perform in the most demanding environments.

Part of the Technology Network

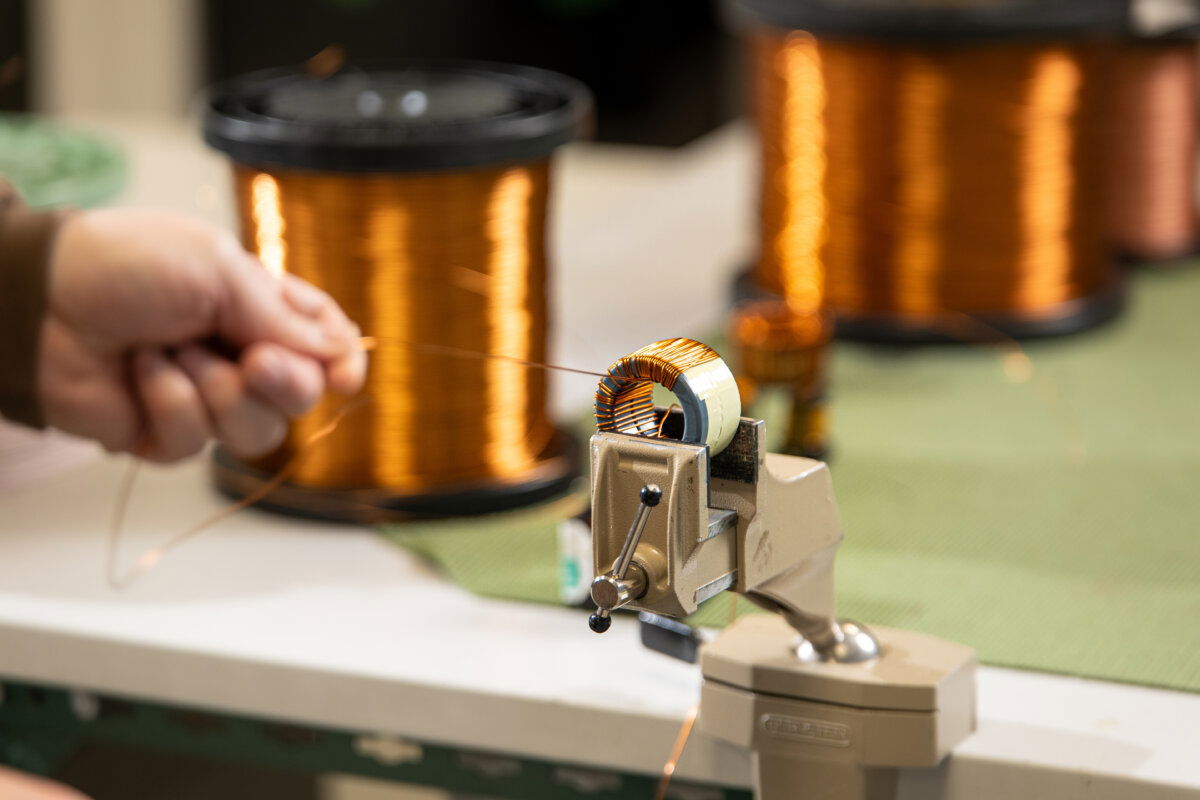

Each Technology Centre is part of Acal BFI’s wider Technology Network, giving you access to a collaborative team of specialist engineers across multiple disciplines. This connected approach allows us to support larger, more complex projects that span multiple technologies – from embedded computing and wireless to power, sensing, photonics, and imaging. By bringing expertise together across our centres, we help reduce design risk, simplify integration, and deliver complete, production-ready solutions through a single, trusted engineering partner.

What we do at the Interconnect and Cable Assembly Technology Centre

The Interconnect and Cable Assembly Technology Centre focuses on delivering ruggedised, high-quality interconnect solutions that balance electrical performance, mechanical robustness, environmental protection, and long-term reliability.

Working as an extension of your engineering teams, we support projects from early specification and design through to assembly, testing, approval, and lifecycle support.

In practice, we help you to:

- Specify the most appropriate connector, cable, and harness solution for harsh environments

- Design and build ruggedised cable assemblies for industrial, defence, and security applications

- Integrate fibre optic, copper, power, and RF technologies within a single connectorised system

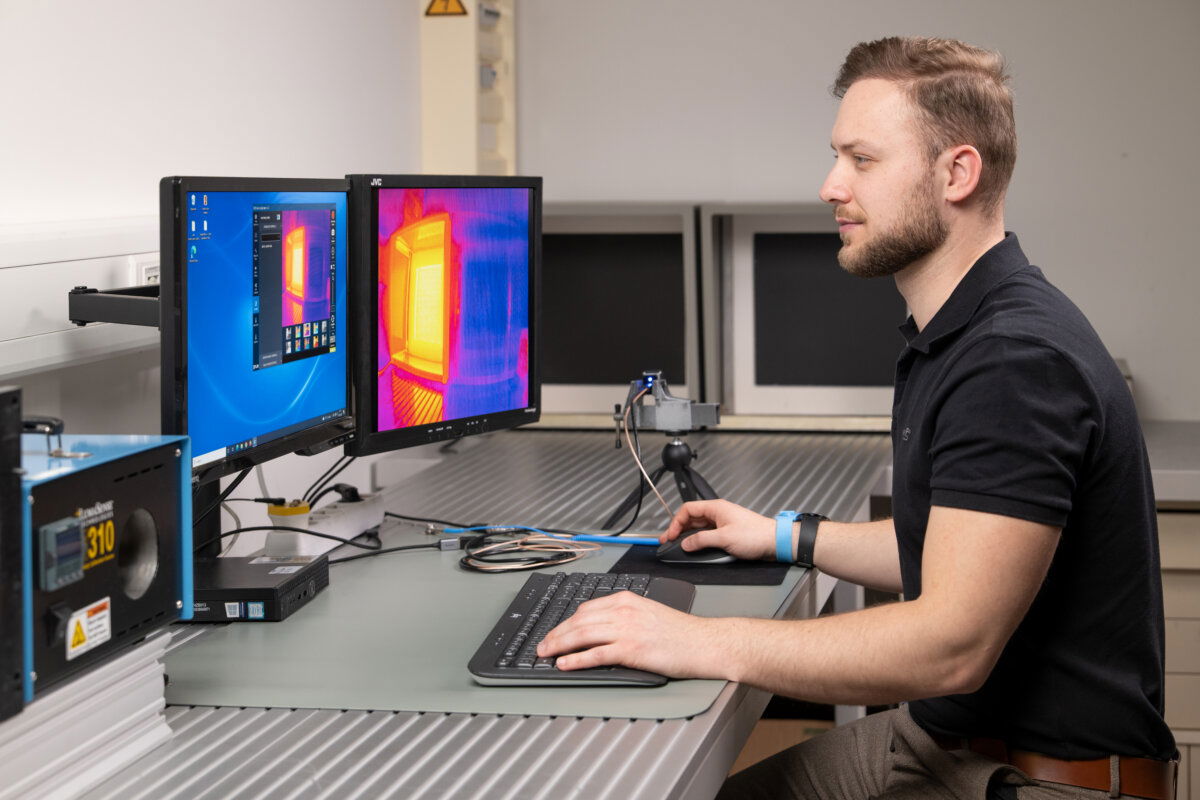

- Reduce approval risk through pre-compliance testing and certified assembly processes

- Ensure consistent quality and long-term supply through controlled manufacturing

Our technical capabilities

The capabilities and expertise housed within the Interconnect and Cable Assembly Technology Centre ensure that our team can support you every step of the way.

From standard assemblies to fully custom cable solutions

The Interconnect and Cable Assembly Technology Centre provides flexible support based on your project requirements.

Collaborative expertise across Acal BFI Technology Centres

The Interconnect and Cable Assembly Technology Centre works closely with our other Technology Centres to deliver fully integrated system solutions. When your project requires additional specialist support, we collaborate with teams from Wireless & IoT, Power Supply, Magnetic Products, and Sensor & Imaging Centres to provide a seamless, multidisciplinary approach. By combining expertise across embedded platforms, power management, connectivity, sensing, and more, we create tailored solutions that address the complex, evolving challenges of modern electronic design.

Why work with the Interconnect and Cable Assembly Technology Centre?

We support engineers and technical decision-makers at every stage of interconnect development, offering:

- Over 50 years of harsh-environment interconnect expertise

- Design-led, engineering-focused support

- Certified UK-based assembly and testing

- Reduced approval and integration risk

- Long-term manufacturer partnerships and supply continuity

Why Acal BFi? Your partner for interconnect and cable assembly solutions

Acal BFi combines deep technical expertise with a broad supplier ecosystem to deliver reliable, application-specific interconnect solutions.

We provide:

- Technical consultation and design support

- Custom and semi-custom cable assemblies

- Fibre optic and hybrid interconnect solutions

- Pre-compliance testing and approvals support

- Long-term lifecycle and supply chain management

Backed by centralised logistics and a pan-European engineering network, we help ensure performance, compliance, and continuity throughout your product’s lifecycle.

Contact the team for an interconnect and cable assembly consultation

Yes. Cable assemblies can be specified and manufactured to operate reliably in demanding environments, including:

-

High and low temperature extremes

-

High vibration and mechanical stress

-

Outdoor and sealed environments (IP-rated solutions)

-

EMC-sensitive applications requiring shielding

-

Industrial, transportation, defence, and medical environments

Appropriate materials, shielding, and strain relief are selected to ensure long-term durability and performance.

Yes. Engineering support is available to help select the most appropriate:

-

Connector types and contact arrangements

-

Cable construction and shielding

-

Power, signal, RF, or high-speed data compatibility

-

Mechanical protection and routing considerations

This ensures signal integrity, reliability, and compliance with your system requirements.

Yes. Lifecycle support helps ensure continuity throughout your product’s lifetime, including:

-

Controlled documentation and revision management

-

Repeatable manufacturing specifications

-

Supply chain and obsolescence management

-

Consistent quality across production batches

This is particularly important for long-lifecycle industrial, medical, and transportation systems.

A bespoke cable harness design is a fully custom interconnect solution built to meet your exact electrical, mechanical, and environmental requirements. It’s ideal for complex systems in industrial, medical, transportation, and defence applications where standard assemblies cannot meet your performance or compliance needs.

Yes. Our team specialises in industrial interconnect solutions and can provide custom cable assemblies designed for high-reliability environments. We offer shielding, over-moulding, strain relief, and ruggedised materials to ensure long-term performance in harsh conditions, including vibration, temperature extremes, and moisture exposure.