Pressure and Force Sensors for Demanding Industrial Designs

Select the right pressure sensor, force sensor, pressure switch or transmitter faster — backed by supplier capability and our in-house application support.

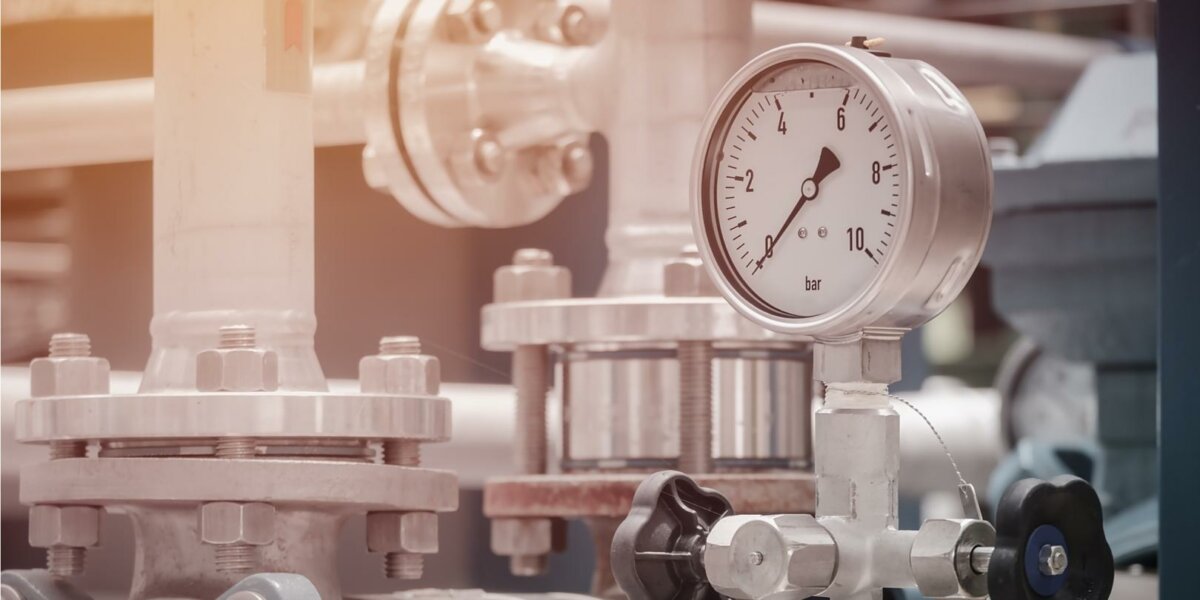

When you are working under tight space constraints or in challenging environments, sensor selection is rarely just about “measuring pressure”. You need the right sensing approach, the right mechanical fit, and a setup that integrates cleanly into your system. We help you route your requirement to the most relevant sensor category — and then support you in narrowing down realistic options without guesswork.

What we offer

- A clear route to the right category: board mounted pressure sensors, media isolated pressure sensors, pressure switches, and pressure transducers and transmitters.

- Access to a broad portfolio backed by supplier capability plus our in-house expertise, so you can make confident selection decisions earlier.

- Support that can include design discussions and, where applicable, access to prototyping and production capability alignment to shorten iteration cycles.

Stronger performance

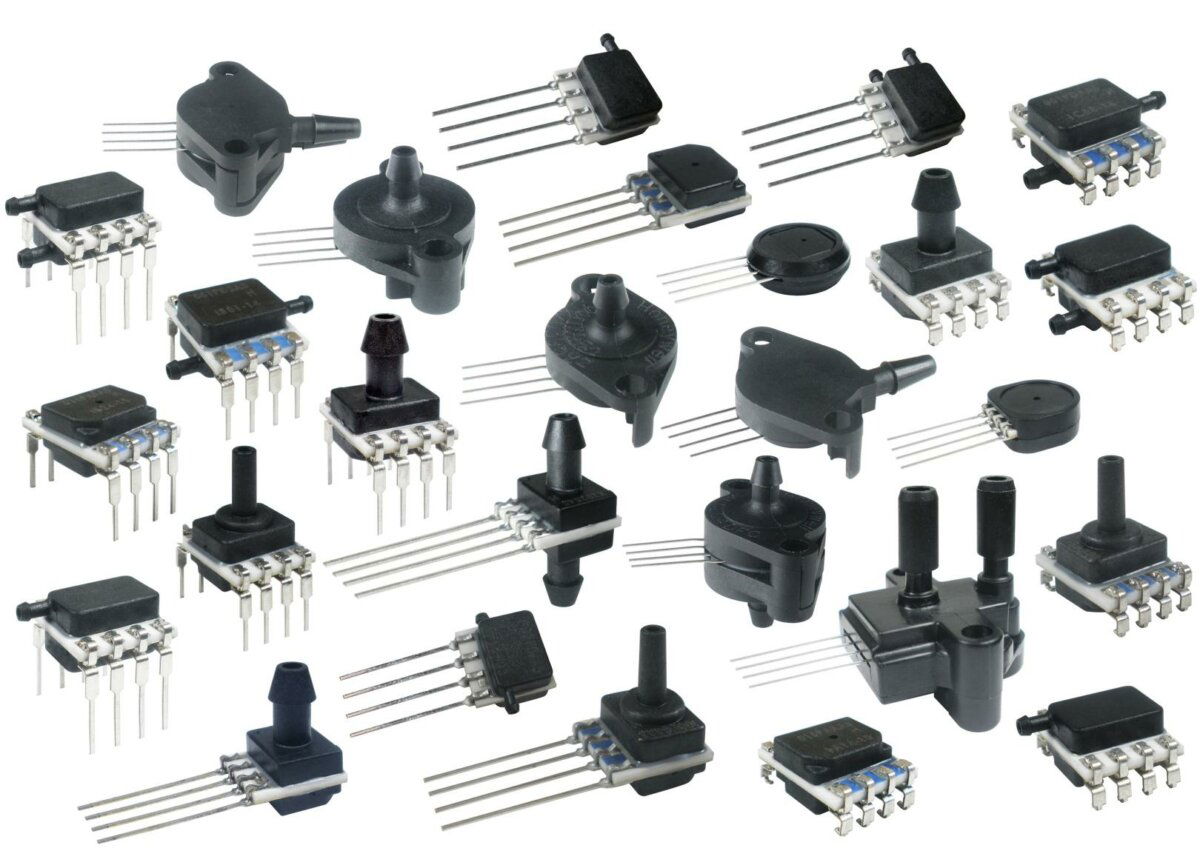

Our portfolio of pressure and force transducers and switches, from world-leading manufacturers, provide a broad range of solutions from basic through to high performance – built for flexibility and sensitivity, for more complex applications. Bringing enhanced precision, ruggedness and endurance, these sensors allow you to meet precise specifications and give stronger performance to your applications.

Choose from board mounted pressure sensors, media isolated pressure sensors and PCB mountable pressure switches as well as a range of combined pressure and temperate transducers, which are well suited to applications where space is tight, and environments are harsh.

Contact us to find out more about the choices and options available to you for a particular application or design.

What you can source from us

We support engineers and technical buyers with a broad portfolio of pressure and force sensing solutions — including pressure switches, pressure transducers and transmitters. Depending on your design, you can route your enquiry to the most relevant category, such as board mounted pressure sensors for compact electronics, media isolated pressure sensors for harsher conditions, or pressure switches when you need a defined switching threshold.

What this helps you solve in real projects

Selecting pressure and force sensors often fails for one simple reason: key constraints are unclear early on (media, mounting, environment, system integration). When that happens, teams waste time comparing sensor families that are not viable — and procurement receives quotes that do not match the real application.

This landing page is designed to make the first decision easier: which category fits your measurement task and constraints. From there, we can help you narrow down the options and reduce redesign risk — without forcing you into a “one-size-fits-all” recommendation.

Why teams choose us for sensor selection support

We combine supplier capability with our in-house expertise to support your selection process and design discussions. Where appropriate, you can benefit from access to advanced prototyping centres and dedicated production capabilities — helping you validate your concept faster and bring designs to market with greater confidence.

If you share a short requirement summary (measurement type, media, range expectations, environment and mounting constraints), we will steer you towards the right sensor category and the most realistic next steps.

FAQs: Selecting the Right Pressure and Force Sensor Faster

A pressure sensor measures force distributed over an area (pressure), while a force sensor measures a load with direction, typically along a single axis. The system consists of the sensing element, the mechanical interface that transfers the load, and the electronics that interpret the signal. The advantage of this method is that you choose based on the real load path in your design, not just the label.

Both strain-gauge and piezoresistive approaches convert mechanical stress into an electrical signal, and either can be used depending on packaging and application constraints. This approach enables higher efficiency by aligning the sensing principle with your mechanical integration, environment and signal conditioning needs. We can guide the selection once your load case and integration constraints are defined.

Choose board mounted pressure sensors when compact PCB integration and tight space constraints drive the design. The advantage of this method is simpler electronics integration because the sensing solution is optimised for PCB-based assemblies. We recommend sharing mounting constraints and the measurement task so we can route you to the right category quickly.

Media isolated pressure sensors are typically used when the application involves harsher conditions and the measured media should be separated from sensitive elements. This approach enables higher efficiency by improving robustness where media exposure or environment can impact stability. We can help shortlist options once media, environment and mechanical interface requirements are clear.

Use a pressure switch when you need a defined on/off action at a preset pressure threshold rather than a continuous measurement signal. The advantage of this method is reduced complexity for protection and control logic where a limit decision is enough. If you need continuous monitoring of gases or liquids, a transducer or transmitter is typically more suitable.

Both provide continuous pressure measurement, but they are typically selected based on how the signal must be delivered and integrated into the system. This approach enables higher efficiency because it matches the measurement output to your controller and wiring constraints. Share your integration expectations and we will guide the correct category choice.

Send the measurement type (pressure or force), whether you need continuous measurement or switching, and your key constraints: media, expected range, environment, and mounting limitations. The system consists of the sensor, the process/mechanical interface, and the electronics interpreting the signal, so each part influences the recommendation. The advantage of this method is a faster shortlist with fewer clarification loops.

Include whether you need pressure or force sensing, continuous measurement or switching, and the key constraints around media, environment, mounting and system integration. The advantage of this method is that we can route you to the correct sensor category immediately and return a realistic shortlist. This approach enables higher efficiency by reducing back-and-forth and avoiding unsuitable options early.