High-Precision MEMS Gyroscopes for Demanding Use Cases

Gyroscopes angular rate sensors

Measuring or maintaining rotational motion, MEMs gyroscopes are small inexpensive sensors that measure angular velocity.

We partner with top-tier manufacturers to bring you sensors best suited to applications such as precision navigation and motion tracking and control.

Our range of gyroscopes and MEMS inertial sensors offer an unrivalled level of performance, including high bias stability, high-performance, superior linearity, increased signal to noise ratio and improved behaviour under harsh vibrations, shocks and temperature environments.

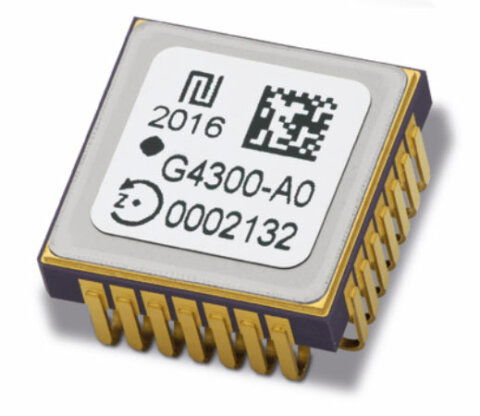

- High-performance MEMS inertial sensor solutions

- Best-in-class bias stability and angular random walk

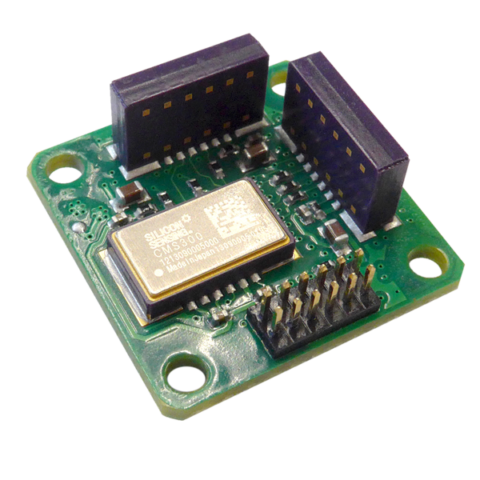

- Packaged, multi-axis inertial solutions