GASEX OEM FTIR gas analyser module with multi-pass heated gas cell

- Technology

- Spectrometers

- Partner

- ARCoptix

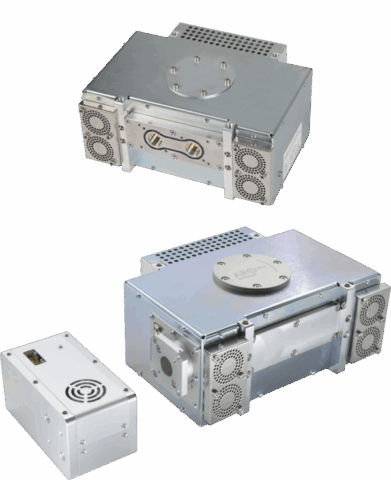

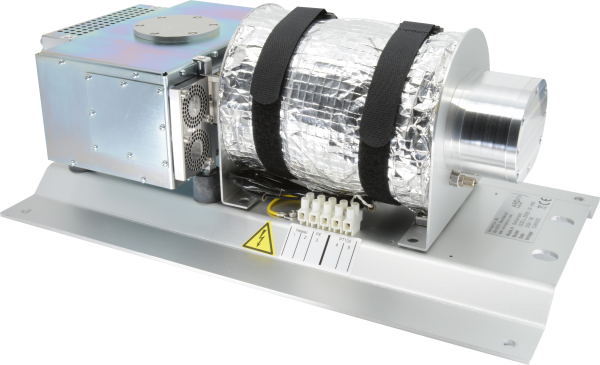

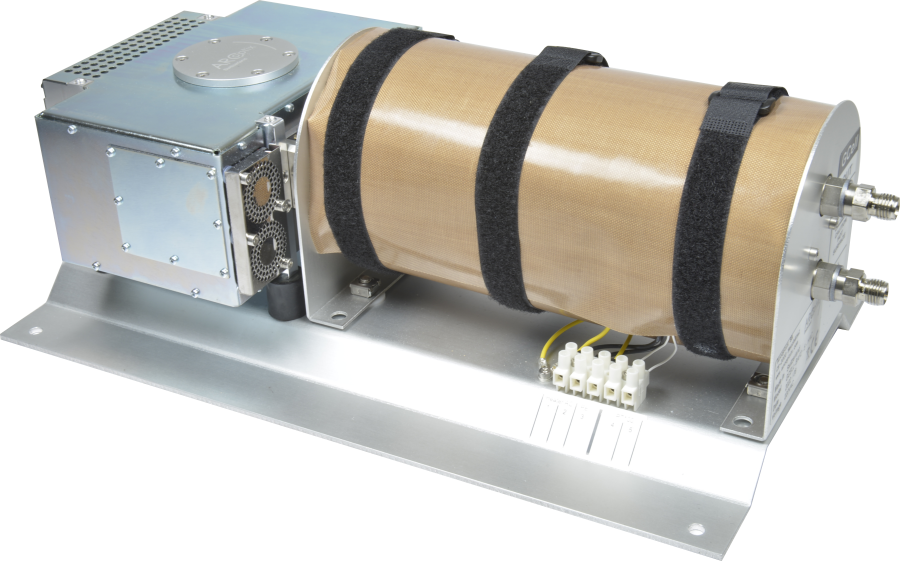

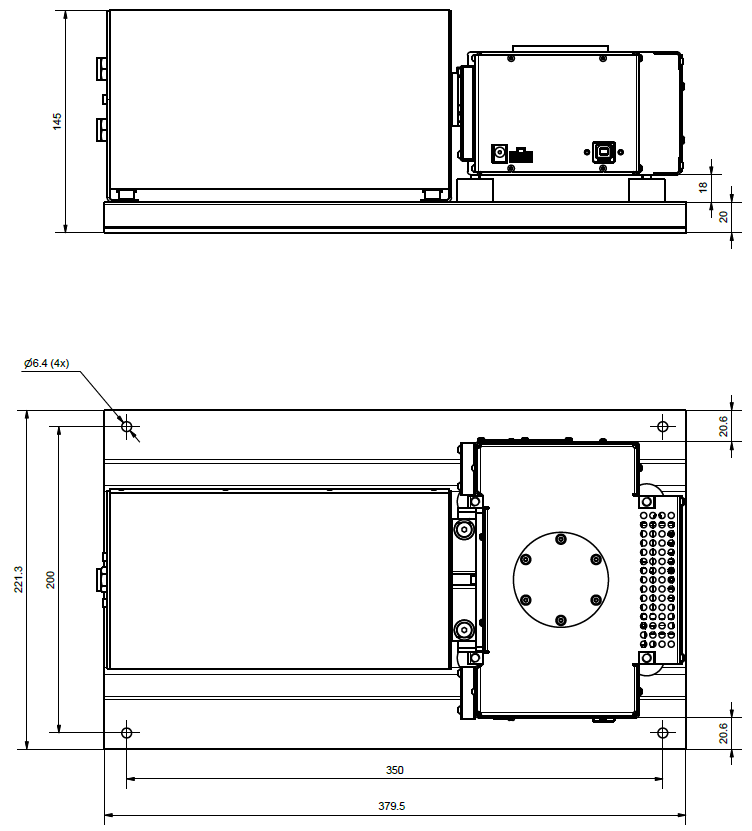

The GASEX OEM FTIR gas analyser module from Arcoptix is an integrated gas analysis platform that pairs the company’s FTIR ROCKET interferometer with a rugged, heated multi-pass gas cell. Designed for OEMs and system builders, it delivers high-resolution infrared spectra for a wide range of gases in industrial emissions, combustion, process and environmental applications.

The small-volume gas cell offers an effective optical path length of up to 5 m while maintaining only 0.2 litres of internal volume, enabling high sensitivity with fast gas exchange. Internal optics with rhodium- and gold-coated mirrors make the cell highly resistant to aggressive and acidic gases such as HF, HCl, HBr, CO, CO₂, NOₓ, NH₃, SO₂, CH₄ and various VOCs.

The FTIR spectrometer uses a permanently aligned dual retro-reflector interferometer and a thermoelectrically cooled MCT detector, providing stable, high signal-to-noise measurements across mid-infrared ranges from 2.0 µm up to 12.0 µm depending on the chosen configuration. USB connectivity and the AoDAQ software platform simplify control, data acquisition and remote operation, whether from a desktop PC or an embedded single-board computer.

Typical detection limits below 1 ppm for many gases, combined with a resolution down to 0.5 cm⁻¹, make the GASEX OEM module suitable for applications that must comply with modern emissions and pollution regulations.

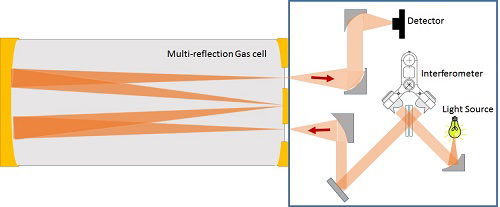

Optical design of the system – Interferometer and multi-pass gas cell

The Gasex system is built around two main elements: an interferometer module and a multi-reflection gas cell. The interferometer module includes the IR light source and an MCT detector.

Infrared light is generated by a blackbody radiation source and then modulated by a dual corner-cube interferometer. After modulation, the light is coupled into the gas cell, where the sample gas is introduced. Inside this so-called “white cell,” the beam is reflected back and forth 32 times, effectively increasing the optical path length and thus the sensitivity of the measurement. Finally, the exiting light is focused onto the MCT detector, where the spectrum is recorded and analysed.

How does the interferometer work? Permanently aligned interferometer

At the heart of the FT-Rocket is a dual corner-cube (retro-reflector) interferometer. Both corner-cubes are mounted on a common swinging arm. When this arm rotates, it creates the optical path difference between the two arms of the interferometer that is needed for Fourier-transform spectroscopy.

This concept is known as a “permanently aligned” interferometer. The geometry is intrinsically stable, making it highly resistant to vibrations and temperature changes, so it does not need realignment over time. The swinging arm itself is supported by a wear-free flexure system, which makes the mechanical design extremely robust and long-lasting.

Solid-state reference laser

To precisely track the movement of the mirrors, a solid-state reference laser is injected into the interferometer. Compared with classic HeNe lasers, the solid-state lasers used here are more compact and offer a much longer lifetime. They also have very low temperature-induced wavelength drift. When temperature-stabilised with a Peltier element, their wavelength can be held stable to within a few ppm, providing a highly accurate and reproducible wavelength scale. This is essential to guarantee consistent results from day to day and from unit to unit.

Range features

A high level overview of what this range offers

- Integrated FTIR spectrometer and multi-pass gas cell: Provides a complete gas analysis module that is ready for OEM integration, avoiding the need to engineer and align separate components.

- Up to 5 m optical path in 0.2 L volume Achieves high sensitivity and low detection limits while maintaining a small gas volume for rapid response and low sample consumption.

- Heated gas cell up to 200 °C: Prevents condensation and supports measurement of wet and corrosive gas streams typical in flue gas, exhaust and process applications.

- Chemically resistant internal optics: Rhodium- and gold-coated mirrors offer excellent durability when exposed to acid gases and aggressive species, reducing maintenance and extending lifetime.

- High-resolution FTIR (down to 0.5 cm⁻¹): Delivers spectral detail sufficient for selective quantification of overlapping gas absorption features and for compliance with emission measurement standards.

- Thermoelectrically cooled MCT detector (2–12 µm range): Combines high detectivity with compact, maintenance-friendly cooling, eliminating the need for liquid nitrogen.

- Permanently aligned dual retro-reflector interferometer: Ensures long-term mechanical stability, robustness against vibration and temperature drift, and removes the need for realignment in the field.

- Active internal H₂O and CO₂ suppression (Absotrans™): – Minimises the influence of water and carbon dioxide inside the interferometer housing, improving baseline stability and measurement repeatability.

- USB interface with AoDAQ software and free GUI: Simplifies communication, configuration and data acquisition, and allows easy integration into higher-level control systems via TCP/IP.

- Open API and development examples: Support for C++, C#, LabVIEW and MATLAB lets OEMs embed the GASEX OEM module into custom control, analysis and automation platforms.

- Compact and lightweight system: Small footprint and low weight ease mechanical integration in rack systems, cabinets or mobile measurement platforms.

- Optional sampling, gas cleaning and calibration accessories: Offer a path to complete, application-specific solutions for corrosive, wet or particulate-laden gas streams.

What’s in this range?

All the variants in the range and a comparison of what they offer

| Parameter | GASEX-OEM-060-4TE | GASEX-OEM-085-4TE | GASEX-OEM-120-4TE |

|---|---|---|---|

Beamsplitter material | CaF₂ | ZnSe | ZnSe |

Spectral range [cm⁻¹] | 5000–1660 | 6600–1200 | 5000–830 |

Spectral range [µm] | 2.0–6.0 | 1.5–8.5 | 2.0–12.0 |

D* [cm Hz¹ᐟ² W⁻¹] |

|

|

|

Signal-to-noise ratio (0.5 cm⁻¹, 1 min scan) |

|

|

|

Technical specifications of the GASEX OEM FTIR gas analyser

| Parameter | Value |

|---|---|

Detector type | MCT, four-stage thermoelectrically cooled |

Interferometer design | Permanently aligned dual retro-reflector |

Available resolutions [cm⁻¹] | 8, 4, 2, 1 or 0.5 |

Wavenumber repeatability | < 10 ppm |

Scan frequency | > 1.5 Hz at 0.5 cm⁻¹ |

Internal reference laser | Temperature-stabilised solid-state laser at 850 nm |

Absotrans™ | Active suppression of water and carbon dioxide inside the interferometer housing |

A/D converter | 24 bit |

Operating temperature | 10–40 °C |

Humidity | Up to 90 % (non-condensing) |

Communication interface | USB 2.0 |

Built-in light source | SiC globar stabilised at 1550 K |

Power requirement (FT-IR only) | < 35 W at 12 V DC |

Software interface | Windows 7/10/11; LabVIEW; .NET-compatible DLL; API for control via Arcoptix DLL |

FAQs

for GASEX OEM FTIR gas analyser module with multi-pass heated gas cell

The GASEX OEM module is designed as an integrated FTIR-based gas analysis platform for OEMs and system integrators. It combines a compact interferometer, IR source and MCT detector with a heated multi-pass gas cell to measure infrared absorption spectra of gases in applications such as emissions monitoring, combustion control, environmental analysis and industrial process monitoring.

According to the product description, the internal coatings and optical design make the system suitable for many common flue and process gases, including acid gases such as HF, HCl and HBr, as well as CO, CO₂, NO, NO₂, NOₓ, NH₃, SO₂, CH₄ and a variety of VOCs. The exact list of quantifiable species will depend on the chosen spectral range, calibration model and application.

The page indicates that typical limits of detection are below 1 ppm for most gases with an integration time of around 20 seconds. Actual performance in a specific installation will depend on optical configuration, gas matrix, cell temperature and the calibration model used.

The multi-pass design forces the IR beam to be reflected back and forth inside the cell many times, giving an effective optical path length of up to 5 m while using a physical cell volume of only 0.2 litres. A longer path length increases the absorption signal for a given gas concentration, allowing the analyser to detect lower concentrations without increasing cell size.

The dual retro-reflector interferometer is mechanically robust and permanently aligned, meaning it does not require periodic realignment even in environments with vibration and temperature variation. This improves long-term stability, ensures consistent wavelength accuracy and reduces service requirements compared with conventional moving-mirror interferometers.

The FTIR module communicates via USB and is supported by the AoDAQ acquisition software, which can run on standard PCs or embedded single-board computers. AoDAQ handles communication with the spectrometer, processes raw signals into spectra and provides a TCP/IP server, so higher-level control or SCADA systems can access data and parameters using simple network commands. In addition, an API and DLLs are supplied with examples for C++, C#, LabVIEW and MATLAB.

A free Windows GUI is provided for basic control, configuration and visualisation of real-time spectra, including functions such as averaging, reference spectra, transmission/reflectance modes and interferogram viewing. For more advanced analysis, third-party Panorama software modules and the IRAnalyze package are offered in collaboration with an external partner, providing tools for multivariate quantification, spectral library search and IR band interpretation.

The FTIR module itself is specified for operation between 10 °C and 40 °C with relative humidity up to 90 % non-condensing. The gas cell can be operated from −20 °C to 200 °C, and includes heaters to stabilise it at around 180 °C, which is important when measuring wet or corrosive gases without condensation.