Acousto-optic modulators

- Technology

- Acousto-optics

- Partner

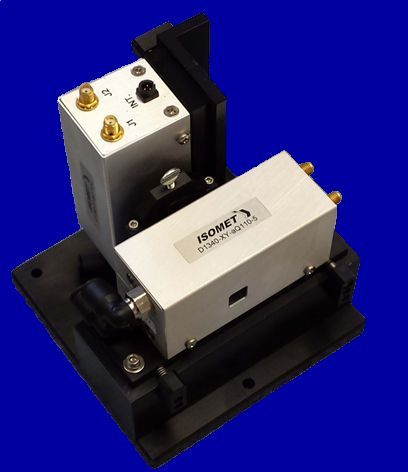

- Isomet

Isomet’s acousto-optic modulators (AOMs) are specially designed for use in laser beam modulation. Applications range from simple on-off switching to intensity modulation and pulse picking of femtosecond lasers.

In-house production facilities such as crystal growing, optical polishing, anti-reflective coatings, vacuum-bonding, and electronics development are the basis for the production of mature and reliable AOMs – naturally also according to special customer requirements. Corresponding RF drivers are also available.

Range features

A high level overview of what this range offers

- Wavelength range: 230nm to 10,600nm

- Optical materials: PbMoO4, TeO2, Ge, SiO2, SF glasses, and quartz

- Rise times: from approx. 7 to 2000ns

- Centre frequencies: ca. 40 – 350MHz

- High diffraction efficiency

-

Active apertures: ca. Ø 0.2mm up to ca. 12 x 30mm²

-

Special designs according to customer requirements available

Suitable RF drivers (analogue and/or digital), synthesisers, power amplifiers and control electronics

What’s in this range?

All the variants in the range and a comparison of what they offer

| Model | Standard A/R [nm] | Material | Active aperture – Ø or height x width [mm] | Typical rise time [ns] / at beam Ø [mm] | Centre frequency [MHz] |

|---|---|---|---|---|---|

M1062-FS40L-5.5 | 325 – 364 | SiO2 | 5.5 | 545 / 5 | 40 |

M1134-FS80L-3 | 325 – 364 | SiO2 | 3 | 327 / 3 | 80 |

M1136B-FS80L-H | 325 – 399 | SiO2 | 1 / 2 / 3 | 109 / 1 | 80 |

M1088-FS110L-H | 325 – 364 | SiO2 | 3 | 327 / 3 | 110 |

M1377-aQ110L-H | 355 | Quartz | 1/ 1.5 / 2 | 171 / 1.5 | 110 |

M1002-T110L-2 | 360 – 420, 442 – 488, 488 – 650 | TeO2 | 2 x 9 | 310 / 2 | 110 |

M1206C-T110L-1 | 360 – 420, 442 – 488, 488 – 650 | TeO2 | 1 | 39 / 0.25 | 110 |

M1340-aQ120-H | 343, 355 | Quartz | 3 / 5 / 7 | 570 / 5 | 120 |

M1212-aQ150-2 | 257, 255 | Quartz | 2 | 228 / 2 | 150 |

M1212-aQ175-1 | 248, 355, 325 – 364 | Quartz | 1 | 57 / 0.5 | 175 |

M1212-aQ200-0.8 | 230, 248, 325 – 364 | Quartz | 0.8 | 23 / 0.2 | 200 |

M1365-aQ215-3 | 266 | Quartz | 3 | 228 / 2 | 215 |

M1250-T260L-0.45 | 360 – 420, 442 – 488, 488 – 633 | TeO2 | 0.45 | 10 / 0.06 | 250 / 260 |

M1201E-SF40-1.7V | 400 – 700 | Glass | 1.7 | 185 / 1 | 40 |

OAM1060-T80S-2 | 532 | TeO2 (S) | 2 | 1000 / 1 | 80 |

M1115-FS80L-3 | 532 | SiO2 | 3 x 6 | 327 / 3 | 80 |

M1133-aQ80L-H | 532 | Quartz | 1,5 / 2 | 114 / 1 | 80 |

M1205-T80L-H | 515 – 640 | TeO2 | 1 / 2 | 31 / 0.25 | 80 |

M1205-P80L-H | 488 – 633 | PbMoO4 | 1 / 2 /3 | 36 / 0.25 | 80 |

M1340-aQ110-H | 515, 532 | Quartz | 3 / 5 | 342 / 3 | 110 |

OAM1020-T100S-3 | 532 | TeO2 (S) | 3 | 2000 / 2 | 110 |

M1206-T110L-1 | 633 – 830 | TeO2 | 1 | 23 / 0.15 | 110 |

M1206-P110L-1 | 488 – 633 | TeO2 | 1 | 27 / 0.15 | 110 |

M1002-T110L-2 | 360 – 420, 442-488, 488 – 650 | TeO2 | 2 x 9 | 155 / 1 | 110 |

M1250-P200L-0.75 | 488 – 633 | PbMoO4 | 0.75 | 12 / 0.065 | 200 |

M1067-T200L | 532 | TeO2 | 0.2 | 10 / 0.065 | 200 |

M1250-T200L-0.5 | 360 – 420, 442 – 488, 488 – 633 | TeO2 | 0.5 | 10 / 0.065 | 200 |

M1250-T260L-0.45 | 360 – 420, 442 – 488, 488 – 633 | TeO2 | 0.45 | 15 / 0.1 | 250 /260 |

M1260-T350L-0.2 | 360 – 420, 442 – 488, 488 – 633 | TeO2 | 0.2 | 7 / 0.045 | 350 |

M1201E-SF40-1.7N | 1060 | Glass | 1.7 | 185 / 1 | 40 |

M1099-T40L-2 | 1900 – 2000 | TeO2 | 2 | 155 / 1 | 40 |

M1137-SF50L-1.5 | 700 – 900, 1064 | SF57 | 1.5 | 191 / 1 | 50 |

M1210-G(fc)-H | 2050, 2500 – 5000 | Ge | 2 / 4 | 118 / 1 | 60 / 80 / 105 |

M1346-aQ(fc)-H | 700 – 900, 1064 | Quartz | 3 / 4 / 5 | 350 | 60 / 68 / 80 |

M1142-SF80L-0.5 | 700 – 900, 1064 | SF57 | 0.5 | 48 / 0.25 | 80 |

M1080-T80L-1.5 | 700 – 900, 1064 | TeO2 | 1.5 | 155 / 1 | 80 |

M1099-T80L-3 | 700 – 900, 1064 | TeO2 | 3 | 310 / 2 | 80 |

M1135-T80L-4 | 1030 – 1100 | TeO2 | 4 | 464 / 3 | 80 |

M1312-T80L-6 | 1030 – 1100 | TeO2 | 6 | 774 / 5 | 80 |

M1133-aQ80L-H | 700 – 900, 1064 | Quartz | 1 / 1.5 / 2 | 114 / 1 | 80 |

M1377-aQ80-H | 700 – 900, 1064 | Quartz | 1 / 2 | 114 / 1 | 80 |

M1362-aQ110-6 | 800 | Quartz | 6 | 570 / 5 | 110 |

M1374-T200L-0.15 | 1064 | TeO2 | 0.15 | 10 / 55 | 200 |

M1260-T350L-0.2 | 633 – 830 | TeO2 | 0.2 | 10 / 0.05 | 350 |

M1205-P80L-H | 633 – 830, 830-1064 | PbMoO4 | 1 / 2 | 179 / 1 | 80 |

M1205-P80L-H(1550) | 1550 | PbMoO4 | 0.6 / 1 / 2 | 90 / 0.5 | 80 |

M1205-T80L-H | 633 – 830 | TeO2 | 1 / 2 | 155 / 1 | 80 |

M1080-T80L-1.5 | 700 – 900, 1064 | TeO2 | 1.5 | 155 / 1 | 80 |

M1206-P110L-1 | 633 – 830 | PbMoO4 | 1 | 179 / 1 | 110 |

M1206-P110L-H | 1550 | PbMoO4 | 0.5 / 1 | 90 / 0.5 | 110 |

M1206-T110-1 | 633 – 830, 830 – 1064 | TeO2 | 1 | 179 / 1 155 / 1 | 110 |

M1250-T150L-0.5 | 633 – 830, 830 – 1064, 1550 | TeO2 | 0.5 | 46 / 0.3 | 150 |

M1250-P200L-0.7 | 633 – 830 | PbMoO4 | 0.7 | 90 / 0.5 | 200 |

M1250-T200L-0.5 | 633 – 830, 830 – 1064, 1550 | TeO2 | 0.5 | 31 / 0.2 | 200 |

M1250-T260L-0.45 | 633 – 830, 830 – 1064, 1550 | TeO2 | 0.45 | 23 / 0.15 | 250 /260 |

| Model | Standard A/R [nm] | Material | Active aperture – Ø or height x width [mm] | Typical rise time [ns] | Bandwidth [MHz] | Centre frequency [MHz] |

|---|---|---|---|---|---|---|

1210-G(fc)-H-MIR | 2050, 2500 – 5000 | Ge | 2 / 4 | 240 | 10 | 60-105 |

M1208-G80-4-MIR | 2050 – 5000 | Ge | 4 x 8 | 500 | 10 | 80 |

M1189-G40-4 | 9300, 10600 | Ge | 4 | 470 | 0.7 | 40 |

M1208-G40-3 | 9400, 10600, 9000 – 11000 | Ge | 3 x 8 | 350 | 1.0 | 40 |

1209-7-1064M | 10600 | Ge | 7 x 14 | 830 | 0.4 | 40 |

1209-7-1112M | 9300, 10600 | Ge | 7 x 14 | 830 | 0.4 | 40 |

1209-9-1010M | 9300, 10600 | Ge | 9 x 20 | 940 | 0.4 | 40 |

AOM640-H | 9400, 9600, 10600 | Ge | 7 x 30, 8 x 30, 9 x 30 | 830 | 0.4 | 40 |

AOM650-H | 9400, 9600, 10600 | Ge | 7 x 30, 8 x 30, 9 x 30 | 830 | 0.4 | 50 |

AOM740-H | 9400, 10600 | Ge | 7 x 30, 8 x 30, 9 x 30 | 830 | 0.4 | 40 |

M1199-G40-H | 9400, 10600 | Ge | 7 x 30, 8 x 30, 9 x 30 | 700 | 0.5 | 40 |

M1310-G40-H | 9400, 10600 | Ge | 7 x 30, 8 x 30, 9 x 30 | 700 | 0.5 | 40 |

M1315-G40-H | 9400, 10600 | Ge | 6 x 15, 7 x 15, 8 x 15, 9 x 15 (only 9400nm) | 700 | 0.5 | 40 |

M1192-G40-12 | 9100 – 9600, 10200 – 10800 | Ge | 12 x 30 | 1200 | 0.3 | 40 |

| Model (dual beam) | Standard A/R [nm] | Material | Max. active aperture height x width [mm] | Typical rise time [ns] | Typical modulation frequency [MHz] | Spot frequency [MHz] |

|---|---|---|---|---|---|---|

AOM650-9 | 9400, 10600 | Ge | 9 x 30 | 600 | 0.6 | 40 / 60 |

M1199-G50-9 | 9000 – 11000 | Ge | 9 x 30 | 600 | 0.6 | 40 / 60 |

DBM1172-G41-9 | 9400, 10600 | Ge | 9 x 20 | 600 | 0.6 | 42 / -43 |

DBM1186-G54-9 | 9300, 10600 | Ge | 9 x 20 | 600 | 0.6 | 54 / -54 |

DBM1199-G54-9 | 9400, 10600 | Ge | 9 x 20 | 600 | 0.6 | 54 / -54 |

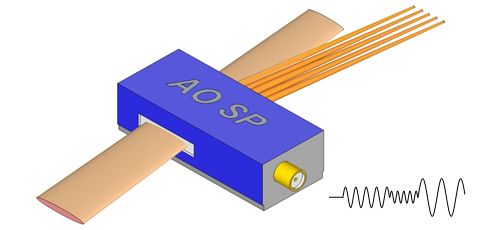

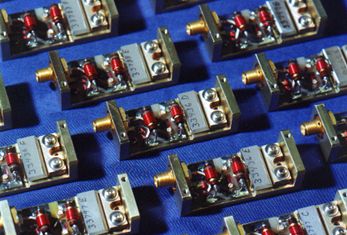

| Model (multi-channel) | Channels | Standard A/R [nm] | Material | Active aperture [mm] | Typical rise time [ns] | Information bandwidth [MHz] | Centre frequency [MHz] |

|---|---|---|---|---|---|---|---|

M1140 | 4 | VIS | PbMoO4 | 0.7 | 25 | 15 | 110 |

G7060 | 6 | IR | Ge | 0.8 | 70 | 5 | 70 |

M8080 | 8 | VIS | PbMoO4 | 0.5 | 55 | 9 | 80 |

M9080C | 8 | VIS | PbMoO4 | 0.7 | 36 | 9 | 90 |

M15080 | 8 | NUV | Quartz | 0.7 | 70 | 5 | 110 |

| Model (with integrated driver) | Standard A/R [nm] | Material | Max. aperture [mm] | Typical rise time [ns] | Typical modulation frequency [MHz] | Centre frequency [MHz] | Modulation |

|---|---|---|---|---|---|---|---|

IMAD-P80L | 450 – 550, 488 – 633, 550 – 650 | PbMoO4 | 1.5 | 25 | 15 | 80 | Analog |

IMDD-P80L | 450 – 500, 488 – 633, 550 – 650 | PbMoO4 | 1.5 | 25 | 15 | 80 | Digital |

IMAD-T110L | 405 – 442 | TeO2 | 1.5 | 25 | 15 | 110 | Analog |

IMDD-T110L | 405 – 442 | TeO2 | 1.5 | 25 | 15 | 110 | Digital |

IMAA-P80L | 488 – 633, 633 – 830 | PbMoO4 | 1.5 | 25 | 15 | 80 | Amplifier only |

FAQs

for Acousto-optic modulators

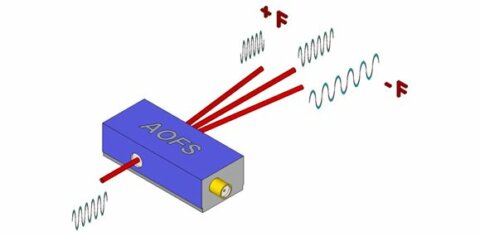

An AOM is an optical device that alters the intensity, frequency, or direction of a laser beam through interaction with ultrasonic waves.

A piezoelectric transducer generates ultrasonic waves in an optical medium. These waves create periodic changes in the refractive index, which diffract and modulate the light.

Acousto-optic modulation is based on the acousto-optic effect (also called Brillouin scattering), where light is scattered by periodic refractive index changes in a medium. These changes are caused by the interaction of an acoustic wave, generated by a piezoelectric transducer, with the light beam.

AOMs are used in laser technology for intensity modulation, frequency shifting, optical switching, and spectroscopy.

Depending on the material, AOMs can be optimised for visible light, infrared, or ultraviolet ranges.

Efficiency varies, but modern AOMs often achieve diffraction efficiencies of 80–90%.

Standard AOMs are designed for a few watts, while specialised models can handle hundreds of watts.

AOMs require radio frequency (RF) drivers that generate the acoustic signal.

By selecting a material with a high sound velocity and driving it at appropriate frequencies.

Beam diameter, divergence, and polarisation affect diffraction efficiency.

Incorrect alignment, insufficient RF power, or unsuitable beam parameters.

Using temperature stabilisation or actively cooling the AOM.

Air or water cooling may be required, especially at high power levels.

Using high-quality drivers and optimised RF cabling helps reduce signal interference.

Yes, AOMs can generate or modulate fast pulses, particularly for Q-switching.

They are used for rapid beam deflection or for generating high-power pulses.

They enable precise frequency modulation and fast switching times for measurements.

Specially designed AOMs with high thermal load capacity are suitable for high-power laser use.