CTK-FC3000 High Power Fibre Laser

- Technology

- Fibre lasers

- Partner

- Coretek

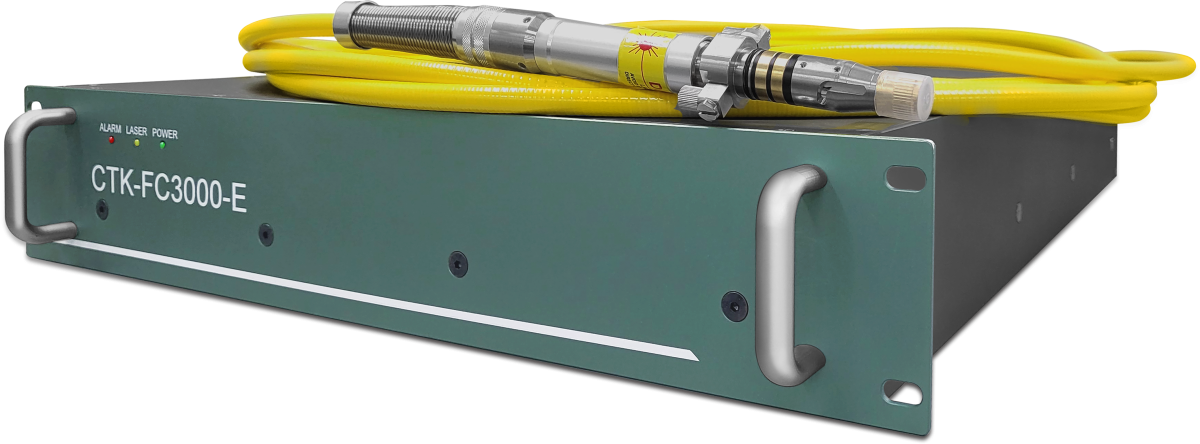

The CTK-FC3000-E and CTK-FC3000-P represent the next generation of high power fibre laser sources for demanding industrial environments. With a continuous output of 3000 W and a wavelength of 1080 nm ±10 nm, these lasers are designed to deliver maximum performance with exceptional reliability.

The system consists of a rugged laser module equipped with a QBH output connector featuring a 100 µm core diameter, paired with a 12-meter output cable for optimal installation flexibility. The technical implementation is based on a modular design concept, allowing easy access for servicing and future upgrades.

These models offer excellent beam quality, even at high power levels, enabling precise and efficient processing of a wide range of materials. This approach enables higher efficiency and repeatability in tasks such as precision cutting, micro- and deep welding, and scientific experimentation. The integrated aiming beam (>0.2 mW at 650 nm) supports accurate positioning and setup alignment.

Compared to previous approaches, the CTK-FC3000 series achieves higher power density and improved thermal management. The simplified control interface ensures quick integration into existing production systems, while minimizing configuration efforts. The components are modular in design, reducing downtime during maintenance and enabling flexible adaptation to different production scenarios.

The focus is on delivering uncompromising power, beam stability, and long-term reliability. It was found that both laser models maintain stable output even in continuous, high-load operation. The results clearly show that the CTK-FC3000 series can meet the expectations of automation-driven industries with ease.

Whether installed in robotic welding cells or integrated into large-scale CNC systems: under consideration of varied user requirements, these lasers are a future-proof solution for complex and high-precision processing tasks.

Range features

A high level overview of what this range offers

- 3000 W output power – for heavy-duty cutting and welding

- 1080 nm ±10 nm wavelength – ensures strong absorption in metals

- Excellent beam quality (QBH, 100 µm) – optimised for deep and wide cuts

- Compact and rugged housing – durable in harsh industrial settings

- 12 m output cable – installation-friendly, even in large setups

- >0.2 mW aiming beam at 650 nm – easy visual alignment

- Simplified control interface – supports fast system integration

- Modular system design – enables cost-efficient maintenance

- Thermal stability at high loads – supports 24/7 production

- High efficiency and low downtime – maximizes productivity and ROI

What’s in this range?

All the variants in the range and a comparison of what they offer

| Parameter | CTK-FC3000-E | CTK-FC3000-P |

|---|---|---|

Power | 3000 W | 3000 W |

Wavelength | 1080 nm ± 10 nm | 1080 nm ± 10 nm |

Output Cable Length | 12 m(Typical) | 12 m(Typical) |

Output Cable Connector(Core Diameter) | QBH(100 um, Typical) | QBH(100 um, Typical) |

Aiming Beam |

|

|

Operation Mode | CW/PWM | CW/PWM |

Polarization | Random | Random |

Power Stability(25°C) |

|

|

Power Adjustment Scope | 10 % – 100 % | 10 % – 100 % |

Max Modulation Frequency | 5 kHz | 5 kHz |

Physical Size(H x W x D) | 89 mm x 482.6 mm x 641 mm | 89 mm x 482.6 mm x 641 mm |

Weight | <45 Kg | <45 Kg |

Power Supply | AC380V ± 10 %, 50/60Hz | AC380V ± 10 %, 50/60Hz |

Power Consumption | 10 kW | 10 kW |

Control Interface | RS232 / DB25 | RS232 / DB25 |

Minimum Water Cooling Capacity | 7.5 kW | 7.5 kW |

Temperature Settings | 25 ± 1°C(Laser Module), 30°C(QBH) | 25 ± 1°C(Laser Module), 30°C(QBH) |

Cooling Tubes Size | Φ 29 x 19 mm(Laser Module), Φ 6 x 4 mm(QBH) | Φ 29 x 19 mm(Laser Module), Φ 6 x 4 mm(QBH) |

Cooling Water Flow Rate(Laser Module) |

|

|

Cooling Water Flow Rate(QBH) | 1.5~2.0 L / min | 1.5~2.0 L / min |

FAQs

for CTK-FC3000 High Power Fibre Laser

The CTK-FC3000-E is equipped with enhanced interface and control options, designed for fully automated production environments. It supports advanced feedback signals, tighter process control, and easier integration into complex machine networks like CNC systems or robotic cells. The CTK-FC3000-P, on the other hand, focuses on core laser performance while offering simplified I/O connectivity. It is ideal for systems with lower automation levels or where cost-efficiency is prioritized. In short: if your setup requires deep integration and flexibility, choose the E model. If your focus is on robust standalone laser performance, the P model is the right choice.

Yes, the CTK-FC3000 series is engineered for 24/7 continuous operation in harsh industrial environments. Its rugged housing, intelligent thermal management, and modular design ensure stable output even under prolonged high-power use. The laser remains thermally stable and optically precise during extended production shifts. Internal monitoring systems protect the laser from overheating or power fluctuations, ensuring safe and long-lasting performance. This makes it particularly well suited for high-throughput cutting lines, automated welding stations, and precision manufacturing processes.

The CTK-FC3000 is optimized for a wide range of materials, including:

- Stainless and carbon steel

- Aluminum and copper

- Titanium and high-performance alloys

Thanks to its 1080 nm wavelength and 100 µm fiber core, the laser achieves high absorption rates even in reflective materials. The good beam quality allows narrow kerf widths and deep penetration, resulting in clean edges and minimal rework. In combination with the right optics, it also handles multi-pass welding, cutting of thick sheets, or heat-sensitive microstructuring with ease. Reflective metals like copper or brass pose no issue, as the fiber laser uses back-reflection-safe architecture.

The CTK-FC3000 series is designed with integration in mind. It comes with a simplified control interface that supports standard industrial protocols such as digital/analog I/O, and optionally RS232 or Ethernet. The E-version especially offers more granular system signals, making it compatible with PLC-controlled machines, robotic systems, or vision-guided processes. Thanks to the well-documented interface and available software support, most users can integrate the laser within a few days – including safety checks and calibration. This fast integration reduces time-to-production and increases system flexibility in both greenfield and retrofit projects.

Routine maintenance of the CTK-FC3000 is intentionally simple and can be performed by trained in-house personnel. Key service points include:

- Visual inspection and cleaning of the QBH connector

- Checking the laser fiber and protective hose for damage

- Verifying the function of status LEDs and safety interlocks

- Monitoring fan filters and cooling water (if applicable)

The modular design allows technicians to replace power modules or interface boards without sending the entire unit back. Optional remote diagnostic support is available to minimize downtime and reduce service costs. In short: the CTK-FC3000 is built to be robust, low-maintenance, and user-serviceable – saving time and money in demanding environments.