CTK-FC1500 High Power Fibre Laser

- Technology

- Fibre lasers

- Partner

- Coretek

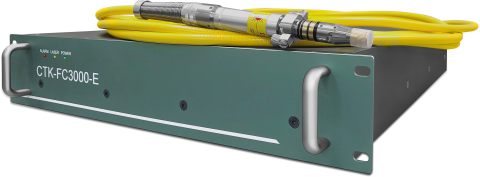

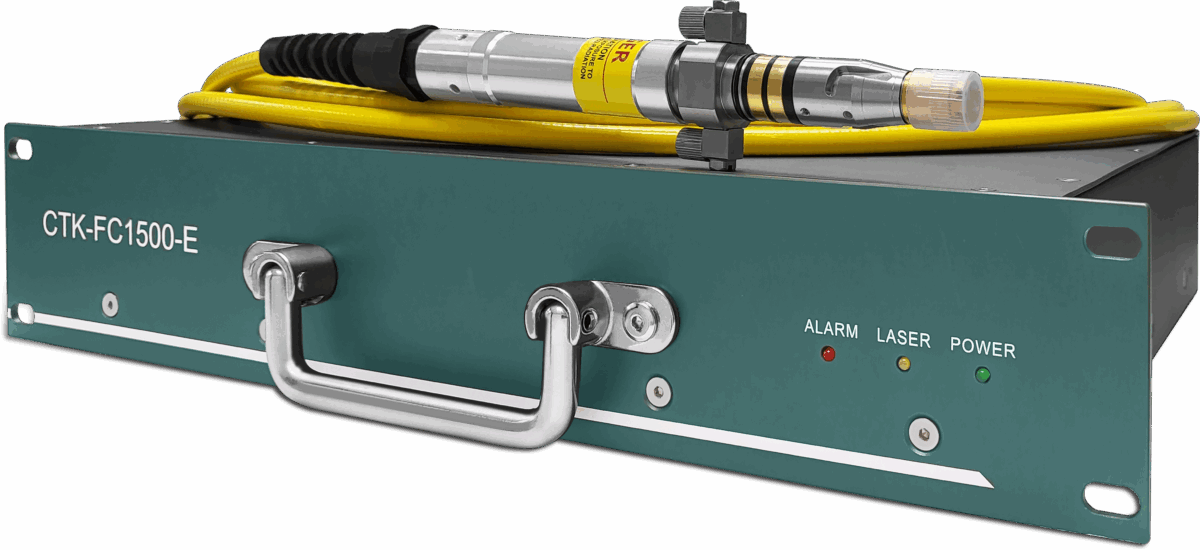

The CTK-FC1500-E and CTK-FC1500-P are high power fibre laser sources developed to meet the demanding requirements of modern manufacturing environments. With a nominal output of 1500 W ±7 % and a wavelength of 1080 nm ±10 nm, these lasers ensure reliable and efficient energy delivery for a wide range of applications.

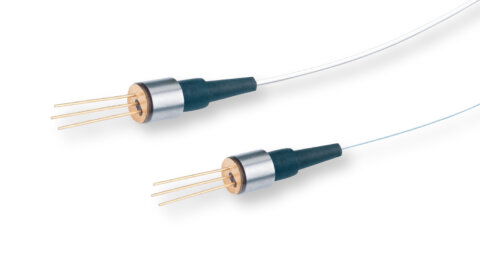

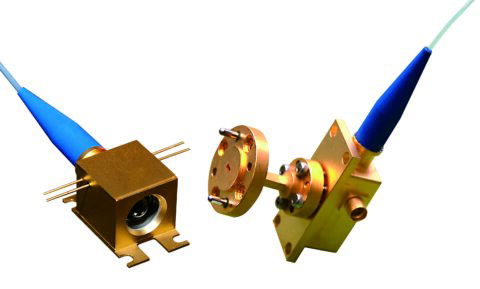

The system consists of a robust laser module integrated into a compact and rugged package. The QBH output connector (50 µm core diameter) and 10 m output cable provide maximum flexibility for installation. The technical implementation is based on a modular concept, enabling straightforward maintenance and future upgrades.

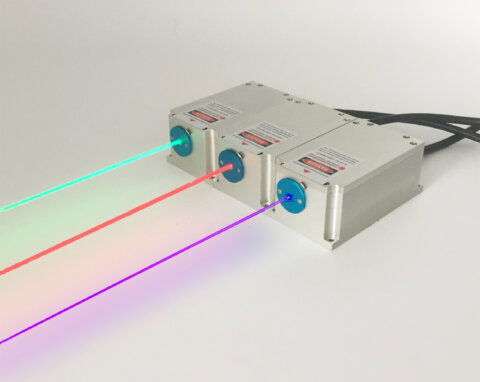

One of the most compelling benefits is the excellent beam quality, which is essential for precise and repeatable results. This approach enables higher efficiency and process stability in tasks such as precision cutting, micro-welding, or scientific research. The integrated >0.2 mW aiming beam at 650 nm supports accurate positioning and setup.

Compared to previous approaches, the CTK-FC1500 series offers enhanced power stability, thermal management, and energy efficiency, resulting in reduced downtime and lower operating costs. The components are modular in design, making service operations faster and more cost-effective.

The focus is on combining maximum performance with ease of use. The simplified control interface connects easily to existing systems, streamlining integration and reducing commissioning time. It was found that even in high-load continuous operation, the system delivers consistent performance with minimal maintenance.

The results clearly show that both models are well-suited for industrial environments, offering both scalability and operational reliability. The measurements confirm the assumption that high power and reliability do not exclude each other—in fact, the CTK-FC1500 series proves that they go hand in hand.

Whether for automated production lines or laboratory setups: under consideration of varied user requirements, these systems offer a versatile and future-proof solution for high-performance laser applications.

Range features

A high level overview of what this range offers

- 1500 W output power – for high-demand cutting and welding

- Wavelength 1080 nm ±10 nm – optimal for metals and composites

- Excellent beam quality – ensures high-precision results

- Compact and rugged design – ideal for industrial environments

- QBH output (50 µm core) – for focused and consistent delivery

- 10 m output cable – simplifies setup in large machines

- Integrated aiming beam (>0.2 mW@650 nm) – precise positioning aid

- Simplified control interface – fast integration and easy use

- Modular architecture – allows flexible upgrades and easy maintenance

- High efficiency and thermal stability – reduces energy usage and downtime

- Reliable operation – proven in long-term performance testing

What’s in this range?

All the variants in the range and a comparison of what they offer

| Parameter | CTK-FC1500-E | CTK-FC1500-P |

|---|---|---|

Power | 1500 W ± 7 % | 1500 W |

Wavelength | 1080 nm ± 10 nm | 1080 nm ± 10 nm |

Output Cable Length | 10 m(Typical) | 10 m(Typical) |

Output Cable Connector (Core Diameter) | QBH(50 um, Typical) | QBH(50 um, Typical) |

Aiming Beam |

|

|

Operation Mode | CW/PWM | CW/PWM |

Polarization | Random | Random |

Power Stability (25°C) |

|

|

Power Adjustment Scope | 10 % – 100 % | 10 % – 100 % |

Max Modulation Frequency | 5 kHz | 5 kHz |

Physical Size (H x W x D) | 75 mm x 402 mm x 295 mm | 89 mm x 482.6 mm x 500 mm |

Weight | 16 Kg | <35 Kg |

Power Supply | AC220V ± 10 %, 50Hz/60Hz | AC220V ± 10 %, 50Hz/60Hz |

Power Consumption | 4 kW | 4.5 kW |

Control Interface | RS232 / DB25 | RS232 / DB25 |

Minimum Water Cooling Capacity | 2.5 kW | 3.5 kW |

Temperature Settings | 25 ± 1°C(Laser Module), 30°C(QBH) | 25 ± 1°C(Laser Module), 30°C(QBH) |

Cooling Tubes Size | Φ 12 x 8 mm(Laser Module), Φ 6 x 4 mm(QBH) | Φ 12 x 8 mm(Laser Module), Φ 6 x 4 mm(QBH) |

Cooling Water Flow Rate (Laser Module) | 8~10 L / min |

|

Cooling Water Flow Rate (QBH) | 1.5~2.0 L / min | 1.5~2.0 L / min |

FAQs

for CTK-FC1500 High Power Fibre Laser

The main difference lies in the control and integration features:

- CTK-FC1500-E offers enhanced monitoring and advanced control interfaces, making it ideal for automation environments.

- CTK-FC1500-P provides a streamlined version focused on performance and cost-efficiency, suitable for manual or semi-automated setups.

This allows customers to choose based on integration depth and budget.

The CTK-FC1500 series is suitable for a wide range of metals, including stainless steel, carbon steel, aluminum, copper, and titanium. Thanks to its 1080 nm wavelength and 50 µm beam core, the laser achieves high absorption and minimal heat distortion in most metal types—ideal for cutting, welding, and surface treatment.

The system is equipped with a QBH output connector and optimized optical design that delivers excellent beam quality (M² < 1.2). This ensures precision, minimal taper in cuts, and reliable weld seams, even under continuous operation or high-power loads.

The laser has a modular design for easy component replacement and minimal downtime. Routine maintenance includes checking fiber optics, cooling systems, and cleaning optical surfaces. The CTK-FC1500 is designed for easy access and tool-free inspection, reducing service effort and cost.

Yes. Both models feature a simplified control interface with standard industrial communication protocols (e.g., analog/digital I/O, RS232, or Ethernet upon request). This enables fast integration into CNC machines, robots, or custom production lines and supports remote diagnostics.