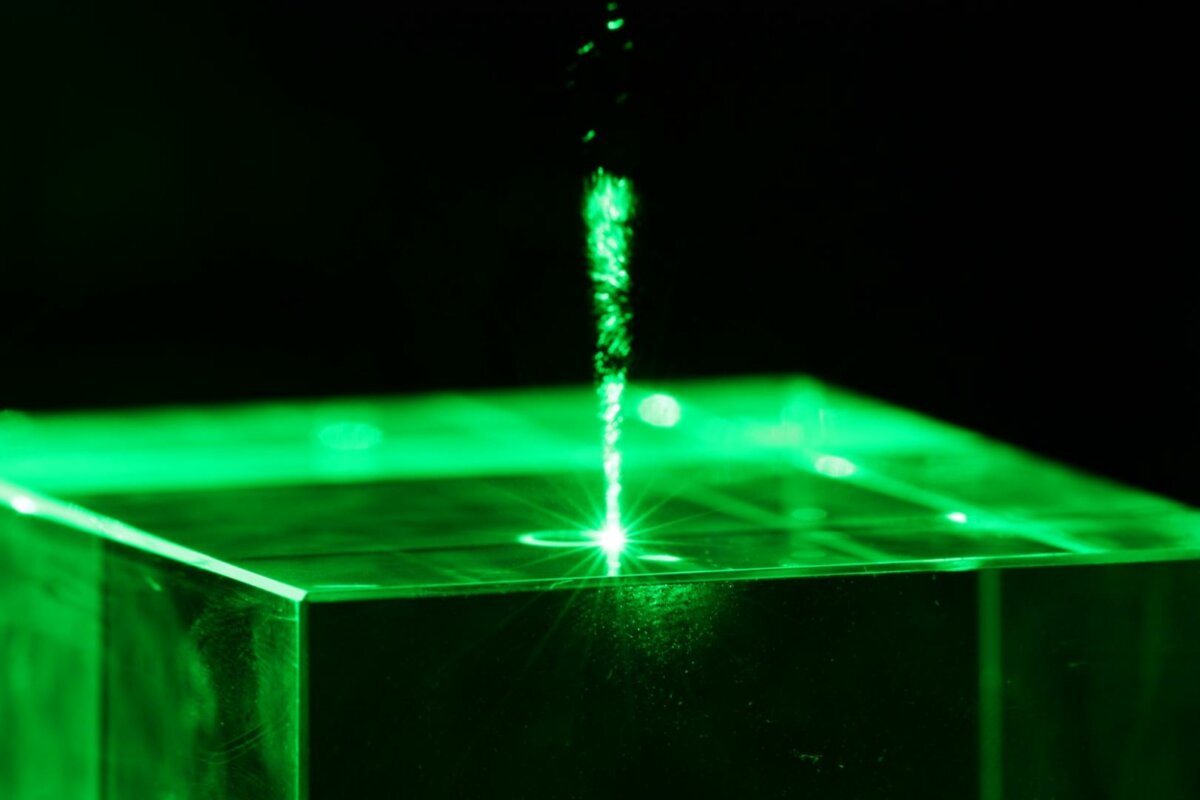

Precision in compact form – DPSS lasers for demanding applications

Our DPSS portfolio at a glance

We offer a broad range of compact DPSS lasers that cover both standard wavelengths such as 532 nm and 1064 nm, as well as tailored configurations designed to meet specific requirements.

Our high-performance DPSS lasers deliver reliable and consistent results across a wide range of applications – including spectral analysis, interferometry, metrology, holography, laser printing, chip inspection, beam collimation, medical laser treatments, and scientific experimentation.

At the end of the day, one thing matters most: reliability.

Our DPSS systems are not only powerful, but also stable over the long term, easy to service, and ideally suited to demanding operating conditions.

These characteristics are also reflected in their technical execution:

DPSS lasers offer excellent sealing, outstanding output power stability, and a wide operating temperature range. The narrow optical bandwidth of the diode lasers allows for efficient, direct pumping of specific laser-active ion transitions – significantly increasing overall system efficiency.

What are DPSS lasers – and why are they in such high demand?

To begin with, it is important to understand that diode pumped solid state lasers – or DPSS lasers – have firmly established themselves as a key technology in both industrial and scientific laser applications. Technically speaking, they are a type of solid-state laser in which the gain medium is excited by a laser diode, rather than traditional gas discharge or flashlamp pumping.

But how exactly does this work?

The diode-based excitation, whether pulsed or continuous, ensures exceptionally stable and energy-efficient laser output. The result is a clear advantage: high beam quality combined with low energy consumption – ideal for precision processing, metrology, biophotonics and OEM integration.

Compact, efficient and durable – The benefits of Diode-Pumped Technology

A good example of this is the use of compact DPSS lasers in fast-paced production environments. Here, the details matter. Thanks to a well-considered system architecture, scalability and efficiency can be achieved simultaneously – even where space is limited. Not least for this reason, it is crucial to rely on laser systems that offer dependable performance under continuous load. In practice, it is often found that a diode pumped laser requires significantly less maintenance than gas-based systems. The performance remains stable even under demanding conditions – whether in continuous operation or in high-power pulsed applications.

Technology that integrates seamlessly

Integration into existing systems is seamless. Our DPSS laser solutions can be embedded effortlessly – whether for precise positioning tasks, spectroscopy, or industrial marking. In combination with other components, they form a coherent overall solution that meets both technical and commercial requirements. Particular attention is paid to interoperability. Put simply: our diode pumped solid state lasers work smoothly with modern control electronics, standardised interfaces and established industrial protocols.

Where DPSS lasers are used – and why it pays to take a closer look

At this point, a brief look at the fundamentals is worthwhile. DPSS lasers are used wherever precise, reproducible, and energy-efficient light sources are required. Typical application areas include:

- Materials processing (micro-cutting, drilling, engraving)

- Metrology and optical sensing

- Medical and laboratory technology

- Semiconductor industry

- Spectroscopy and fluorescence excitation

What makes this solution particularly efficient? The low heat generation, high conversion efficiency, and compact form factor speak for themselves. This advantage is hard to ignore.

Your Next Step – Why is it worth switching to DPSS technology?

- What specific benefits does it offer in real-world applications?

- How can the technology be integrated into existing systems?

- What challenges should be taken into account?

- When does it make sense to transition to this technology?

Our experts are here to support you – get in touch and discover the full potential of diode pumped solid state laser technology for your application.

FAQs about DPSS laser technology

DPSS lasers offer significantly higher efficiency, superior beam quality and reduced thermal load. By using direct diode pumping, energy is transferred with minimal loss, enabling compact designs, long operational lifetimes and very low maintenance requirements. This approach ensures stable and precise performance – even under demanding operating conditions.

DPSS lasers are available directly from Acal BFi. As an experienced technology partner, we provide expert advice, access to high-quality DPSS laser systems, and tailored support for seamless integration into your application. Contact our team to find the right solution for your specific requirements.

DPSS lasers are widely used in metrology, spectroscopy, holography, semiconductor inspection, fluorescence excitation, medical diagnostics and laser printing. Their high stability, narrow linewidth and low noise levels make them ideal for any application requiring consistent optical output and long-term reliability.

Our DPSS systems feature advanced thermal and electronic regulation that ensures exceptionally stable output power – typically with a deviation of less than ±1 %. This is particularly critical in precision measurement applications, where even the slightest fluctuation can affect results.

We offer standard wavelengths such as 532 nm, 1064 nm, 355 nm, 266 nm, 671 nm and 447 nm, as well as application-specific custom options. These are based on common laser-active media such as Nd:YAG, with optional frequency doubling or tripling to produce the desired output spectrum.

Compact DPSS lasers combine a small footprint with excellent beam quality, thermal stability and long service life. Thanks to standardised mechanical interfaces, TTL/analogue modulation capabilities and digital control protocols, they can be easily integrated into OEM systems and compact instruments.

Using laser diodes allows the excitation energy to be directed straight into the absorption bands of the laser medium – without the inefficiencies of traditional light sources. This reduces heat losses, lowers cooling requirements and increases overall wall-plug efficiency. In practical terms, this means more optical output with less energy input.

Our systems are designed for industrial use and support a wide operating temperature range (typically 15 °C to 35 °C for air-cooled variants). Depending on the model, the housings are sealed against dust and moisture. This ensures reliable operation even in harsh or uncontrolled environments.

Yes – we offer both hardware and firmware modifications to tailor our lasers to your specific application. This includes custom beam profiles, fibre-coupled output, extended modulation functions, special mounting formats or integration into multi-wavelength systems. Our engineering team will work closely with you throughout the entire design-in process.