High Temperature and Performance Alloys

- Technology

- Powder cores

- Partner

- Micrometals

Delivering exceptional performance and reliability, Micrometals magnetic alloy materials are specifically designed for intense power applications where cores are exposed to or generate extremely high temperatures. These cost-competitive alloy core materials are not subject to thermal aging for operating temperatures up to 200°C.

Range features

A high level overview of what this range offers

- Available in core sizes from OD 4.06mm up to 165.1mm

- Permeabilities up to 125 (for M125 material)

- No thermal aging and operating temperature up to 200°C

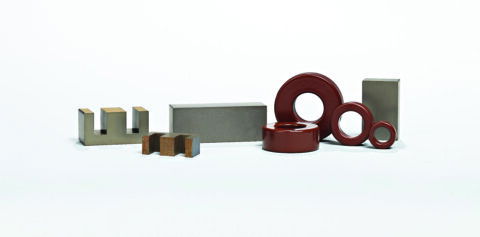

- Available in different shapes

- Very low loss powder materials

- Operating frequencies ≤200kHz

What’s in this range?

All the variants in the range and a comparison of what they offer

| Material mix | Reference permeability | Powder type | Density (gm/cm3) | Available shapes | Relative cost | Colour code toroid |

|---|---|---|---|---|---|---|

60 | 55 | Silicon-iron | 6.1 | Toroid, E-core, RC core | 2.2 | Brown/black |

61 | 35 | Silicon-iron | 6.1 | Toroid, disc | 2.2 | Brown/grey |

63 | 35 | Silicon-iron | 5.9 | Toroid, E-core, block, I-core | 3.7 | Brown/beige |

65 | 42 | Silicon-iron | 6.1 | HC, IC, ID, SC | 2.0 | Brown/yellow |

66 | 66 | Silicon-iron | 6.2 | Toroid, E-core, block, bus bar, HC, HD, IC, ID, RC, SC, | 2.9 | Brown/brown |

70 | 100 | Nickel-iron | 7.4 | Toroid, E-core | 14 | Beige/black |

M125 | 125 | Molypermalloy | 7.7 | Toroid | 15 | Lt blue/lt blue |