Powder cores

Powder cores cover a huge range in terms of materials, often derived from common sheet or ribbon materials, and shapes/sizes.

The major material classes iron, alloys, nickel-iron-molybdenum, iron-silicon, iron-silicon-aluminium, amorphous, and nanocrystalline are sub-divided into materials optimised for certain permeabilities, saturation behaviour, and frequency ranges.

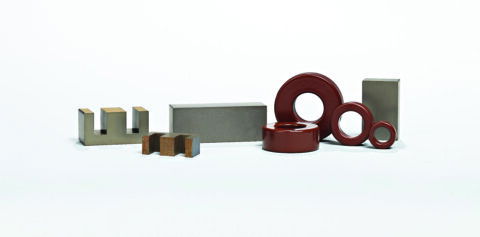

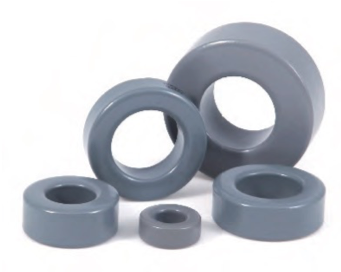

Parts are pressed from powder cores, so any shape which can be formed with a pressing tool can be designed. Available standard shapes comprise cores suited for bobbin or direct windings, bars, or plates.

Powder cores are mainly used for chokes and magnetic inductors in power applications, but – especially iron powder parts – also as magnetic construction elements. We offer the entire range of combinations of material and shapes, with the option to design customised solutions. Our engineers together with our partners help to find the optimum solution in terms of performance and costs.