Nanocrystalline cores

- Technology

- Nanocrystalline cores

- Partner

- Magnetics Inc.

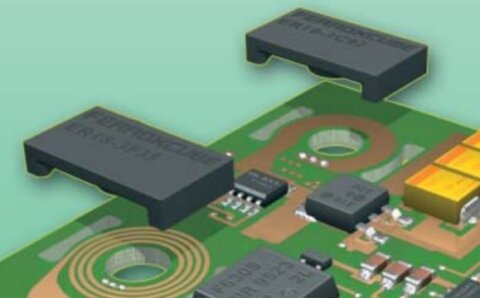

Nanocrystalline cores are an excellent choice for common mode choke (CMC) applications thanks to their high permeability, low power loss, and high saturation induction. Common mode chokes made with nanocrystalline material are widely used in switched-mode power supplies (SMPS), uninterruptible power supplies (UPS), solar inverters, frequency converters, EMC filters, EV chargers, and various automotive and welding applications. Compared to ferrite cores, nanocrystalline cores offer a broader operational temperature range and significantly higher impedance at high frequencies.

The high permeability of nanocrystalline cores allows common mode chokes, current transformers, and magnetic amplifiers (magamps) to be smaller in size while handling higher currents. With a saturation induction of 1.25 T and a wide temperature range, CMCs made with nanocrystalline cores are less prone to current imbalance and performance degradation at elevated temperatures. Their low AC losses ensure excellent efficiency, while durable case options—such as polyester (up to 130 °C) and Rynite polyester (up to 155 °C)—make them suitable for winding with thicker wire.

Range features

A high level over view of what this range offers

- High permeability for improved performance

- Low power (AC) losses for better efficiency

- High saturation induction (~1.25 T) for handling higher currents

- Smaller size and lighter weight compared to ferrite cores

- Wider operational temperature range (up to 155°C with Rynite polyester casing)

- Higher impedance at high frequencies for enhanced noise suppression

- Reduced susceptibility to current imbalance and performance loss at high temperatures

- Suitable for thick wire winding with durable polyester and Rynite polyester cases

- Applicable in SMPS, UPS, solar inverters, EMC filters, EV chargers, automotive, and welding applications