MnZn and NiZn ferrite cores for EMC, signal and power applications

Ferrite cores for your application – precise materials, maximum performance

We offer a wide range of ferrite cores in terms of materials (i.e. properties) and shapes and sizes.

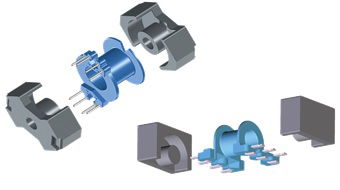

The two major materials classes Mn-Zn and Ni-Zn are sub-divided into materials optimised for power, signal, and EMI shielding applications, or special functionality like shielding – with further material grades designed for certain permeabilities, frequency ranges, and temperature behaviour. Ferrite core parts are pressed from powder cores and sintered, meaning any shape which can be formed with a pressing tool can be designed. Available standard shapes comprise cores suited for bobbin or direct windings, bars, rods, plates, and tiles.

We offer the entire range of combinations of material and shapes, with the option to design customised solutions. Our engineers together with our partners help to find the optimum solution in terms of performance and costs.

Ferrite Core FAQs – Properties, Materials, and Applications

Frequently Asked Questions about Ferrite cores

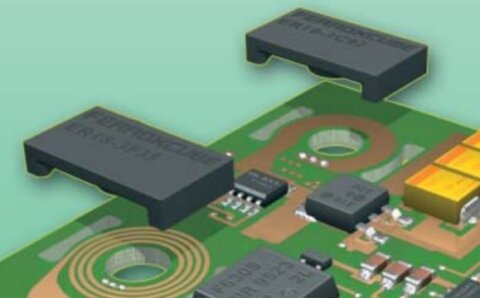

Typical applications for MnZn ferrites include transformers and chokes in switch-mode power supplies and power converters operating at frequencies above approx. 5 kHz. They are also used in electrical filters to suppress interference within specific frequency ranges. Chokes can be storage chokes (with air gaps in the core) or common mode chokes. Storage chokes are used in (push-pull) filter circuits, input and output filters, as well as in buck, boost, or PFC chokes. Additional applications include antenna systems in communication and inductive sensors in sensor technology.

Acal BFi offers a wide range of MnZn and NiZn ferrite materials. Please contact our Sales Team or MagTC Team for more detailed information.

We are happy to supply ferrite cores according to your drawings and specifications. Depending on the material, samples up to sizes of 120×78×30 mm or 150×50×45 mm can be milled from a ferrite block without incurring tooling costs. For larger cores, a press tool is required, which incurs tooling costs.

You can purchase ferrite cores directly from Acal BFi. We offer technical consultation, samples, and customised solutions tailored to your requirements. Our Sales and MagTC teams will support you from selection to delivery. Contact us for more information or to place your order.

Permeability describes a ferrite core’s ability to concentrate magnetic field lines and conduct magnetic flux. High permeability reduces magnetic resistance and increases inductance – a key property in transformers and chokes. Permeability depends on external influences such as temperature and pressure, as well as on the application frequency.

Core losses consist of hysteresis losses, eddy current losses, and residual losses. These losses increase with frequency and result in heat. To maximise efficiency, soft magnetic materials with low hysteresis losses and low electrical conductivity are used to minimise eddy currents, especially in high-frequency applications.

Ferrite cores can be optimised for frequencies ranging from a few kilohertz up to the gigahertz range. Power transformers typically use MnZn ferrites below 1 MHz, while EMI ferrites based on NiZn are used for frequencies above 100 MHz.

MnZn ferrites have higher permeability (approx. 500 to over 15,000) and are mainly used for frequencies up to around 2 MHz. They are commonly found in power applications and filters. NiZn ferrites have lower permeability (10 to 2,000) but higher electrical resistance, making them suitable for higher frequencies (above 100 MHz). They are often used in communication applications.

Ferrite cores act as frequency-dependent resistors for high-frequency signals. They absorb electromagnetic interference by converting energy into heat. This is optimised through the selection of materials with high loss rates in the GHz range.

Saturation flux density defines the limit beyond which a core material can no longer conduct additional magnetic flux. It is one of the key properties of a soft magnetic material. B_sat depends heavily on the material composition and decreases with rising temperature. For switch-mode power supplies and power transformers, B_sat values above 300 mT are desirable, while for high-frequency applications, values below 200 mT are often acceptable.

The Curie temperature (T_C) marks the threshold above which a ferrite loses its magnetic properties. Once this temperature is exceeded, the relative permeability drops towards 1. Typical ferrite materials have T_C values between 100 °C and 500 °C. High-temperature applications require materials with a high Curie temperature to prevent unwanted demagnetisation.

Geometry determines the effective magnetic path length (l_e) and cross-sectional area (A_e). Together with permeability, these define a core’s inductance. A larger cross-sectional area reduces magnetic flux density (B), which delays saturation, while a longer magnetic path reduces total inductance.

Air gaps are introduced to reduce the effective permeability and thereby limit the magnetic flux, preventing core saturation. They also reduce hysteresis losses and improve linearity in applications such as chokes and flyback transformers. Air gaps also help reduce temperature dependence and tolerances of permeability. The gap size is precisely selected to achieve the desired magnetic characteristics.

Key parameters include permeability, core losses, saturation flux density, Curie temperature, mechanical stability, air gap, electrical resistivity, and the operational frequency range. The right combination of these factors determines a ferrite core’s performance in a given circuit.