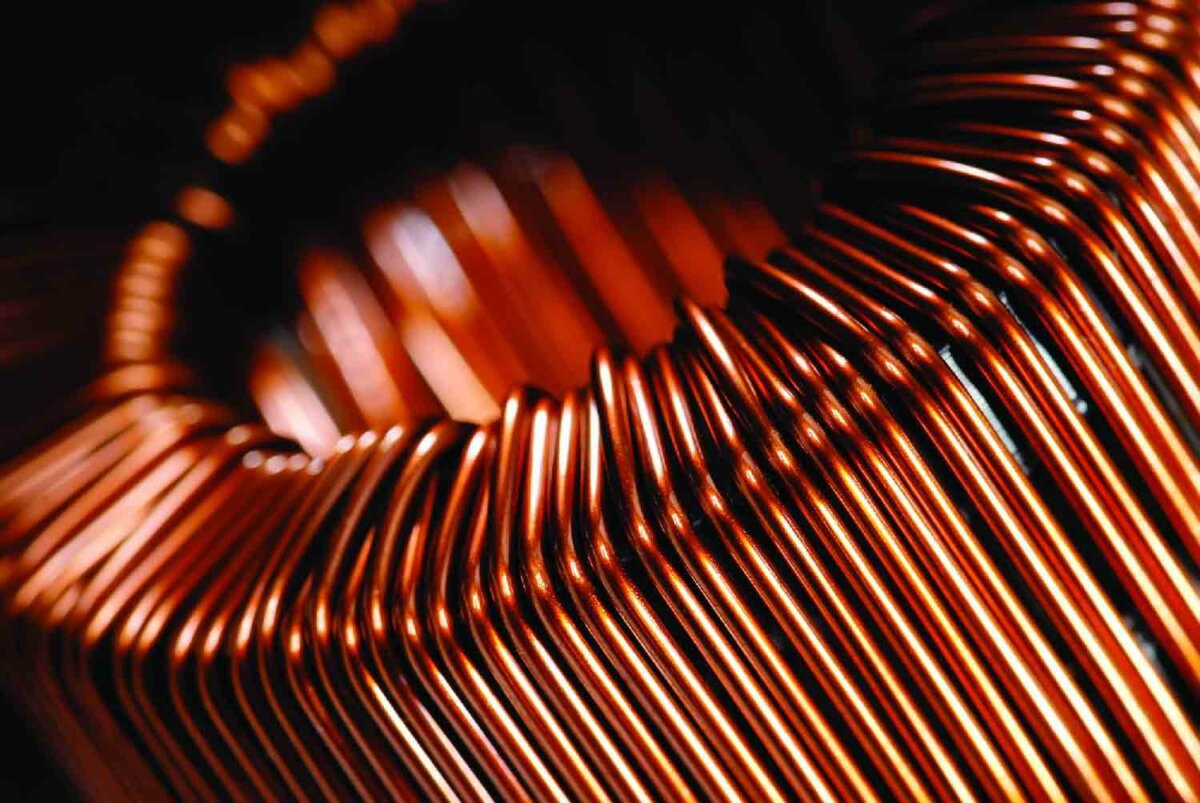

Magnetic cores

Find the perfect match for inductive components’ requirements.

Our world-class range of magnetic cores offer the highest quality and flexibility to meet even complex specifications. These products are ideal for power (energy conversion) and EMI shielding applications, and signal processing, sensor, and as well as testing.

We offer a unique combination of design expertise and working with world-leading suppliers and acting as your technical partner to help solve design challenges.

Discover our range of technologies

FAQs about our magnetic cores for power electronics, EMI & sensing

Magnetic cores FAQs

Magnetic cores are shaped soft-magnetic structures that confine flux for energy storage, transfer, sensing, and EMI control; families include ferrite, amorphous, nanocrystalline, nickel-iron alloys, and alloy powder systems. Each magnetic core material trades permeability, saturation, frequency loss and temperature behavior—so selection depends on whether the duty is power conversion, current measurement, or EMI suppression

MnZn/NiZn ferrite offers low high-frequency loss and many shapes for SMPS, signal, and shielding; alloy magnetic cores (e.g., Ni-Fe, Fe-Si, amorphous) provide higher saturation or tailored permeability for low–mid kHz transformers and precision CTs. The best choice balances Steinmetz loss, permeability vs. bias, and the application’s thermal envelope.

An oval-shaped magnetic core (or racetrack) increases window length for multi-turn windings and can lower leakage for bus-bar style chokes while keeping profile low; it’s common in EMI chokes and compact inductors where geometry aids assembly. Because ferrites are pressed ceramics, many non-round shapes—including oval and rectangular ferrite core variants—are feasible with the right tooling.

Soft magnetic cores minimise hysteresis while allowing rapid flux change; powder cores (Fe, FeSi, FeSiAl, NiFeMo) distribute an effective gap to keep inductance stable with DC bias, whereas ferrites minimise AC loss at higher kHz. Selecting between powder and ferrite depends on required inductance stability, ripple current, and target switching frequency.

Nanocrystalline tape-wound rings offer very high permeability and low loss, making a nanocrystalline core for EMI suppression ideal for common-mode chokes and motor-bearing current mitigation; NiZn ferrite sleeves and clamp cores remain staples for cable EMI. Application notes and case studies show size reductions and improved EMC with nanocrystalline CMCs.

In core magnetics, Ni-Fe tape-wound alloys deliver very high permeability and low coercivity for precision CTs and low-frequency magnetics, with thin ribbons pushing useful operation toward tens of kHz; ferrite remains superior for lowest loss above ~100–300 kHz. Engineers often pair Ni-Fe CT cores with ferrite power magnetics in the same converter.

Yes; pressed ferrite enables E, EE, RM, EP/LP, planar ER, balun, and custom prismatic shapes, including rectangular ferrite core sets and accessories (clips, bobbins, housings) for fast assembly and consistent creepage/clearance. Shape choice directly tunes leakage, capacitance, and manufacturability.

Powder systems (e.g., MPP, Kool Mµ, XFlux, Fe-nanocrystalline powder) are magnetics cores that trade a bit more AC loss for excellent DC-bias linearity and soft saturation—great for PFC chokes, output inductors, and in-line filters. Datasheets specify permeability sets, bias curves, Curie temperature, and frequency-dependent core loss to size your part accurately. acalbfi.com +4

Acal BFi partners with leading magnetic core manufacturers (e.g., Magnetics Inc., Ferroxcube, Laird, Magnetec, and our Acal BFi kOr brand) to cover ferrite, powder, amorphous and nanocrystalline families; we also provide engineered customs via our Magnetics Products Technology Centre —so in practice we function as a magnetic core manufacturer for bespoke geometries and materials.

Yes—share topology, frequency, ripple/bias, temperature, isolation and size limits, and we will map the right magnetics core and geometry (toroid, planar set, RM, oval-shaped magnetic core, or rectangular ferrite core) to your target. We compare magnetic core materials (ferrite, powder, Ni-Fe alloy, amorphous, nanocrystalline) against your EMI and efficiency goals, then recommend catalogue or custom options with accessories for production.