Magnetic components

It all starts with the right magnetic component.

We provide the best magnetic components available and support your design, integration, and manufacturing to create optimal performing applications. Used for control, transfer, and conditioning of electric power and signals, magnetic components play an essential role in any electronic application. The success of a great design relies on the correct selection of the right magnetic components.

With technical expertise gained over 40 years in the market, we offer you a comprehensive range of magnetic components that meet all your technical design needs. Our close relationships with world-class, innovative manufacturers mean we can help you to source, customise, and integrate any magnetic components for your unique application.

Innovating power applications with cutting-edge technical solutions

Our technical teams are at the forefront of technology development, ensuring that our technical advice and range of products feature the latest materials, topologies, and processes in order to continually improve the technical performance of power applications. For complex component requirements and to help solve more complex design challenges, we can design and build a complete solution to your needs with custom-designed solutions.

Our in-house design engineers from our Magnetics Products Technology Centre have been helping customers with custom magnetic inductors and transformers for over 25 years, and our technical teams have extensive experience across a range of sectors including renewable energy, EV-charging, uninterruptible power supplies (UPS), industrial welding, electrical drives, ship building, automotive, and rail, medical equipment, and aerospace.

Magnetic Components — Technical FAQs

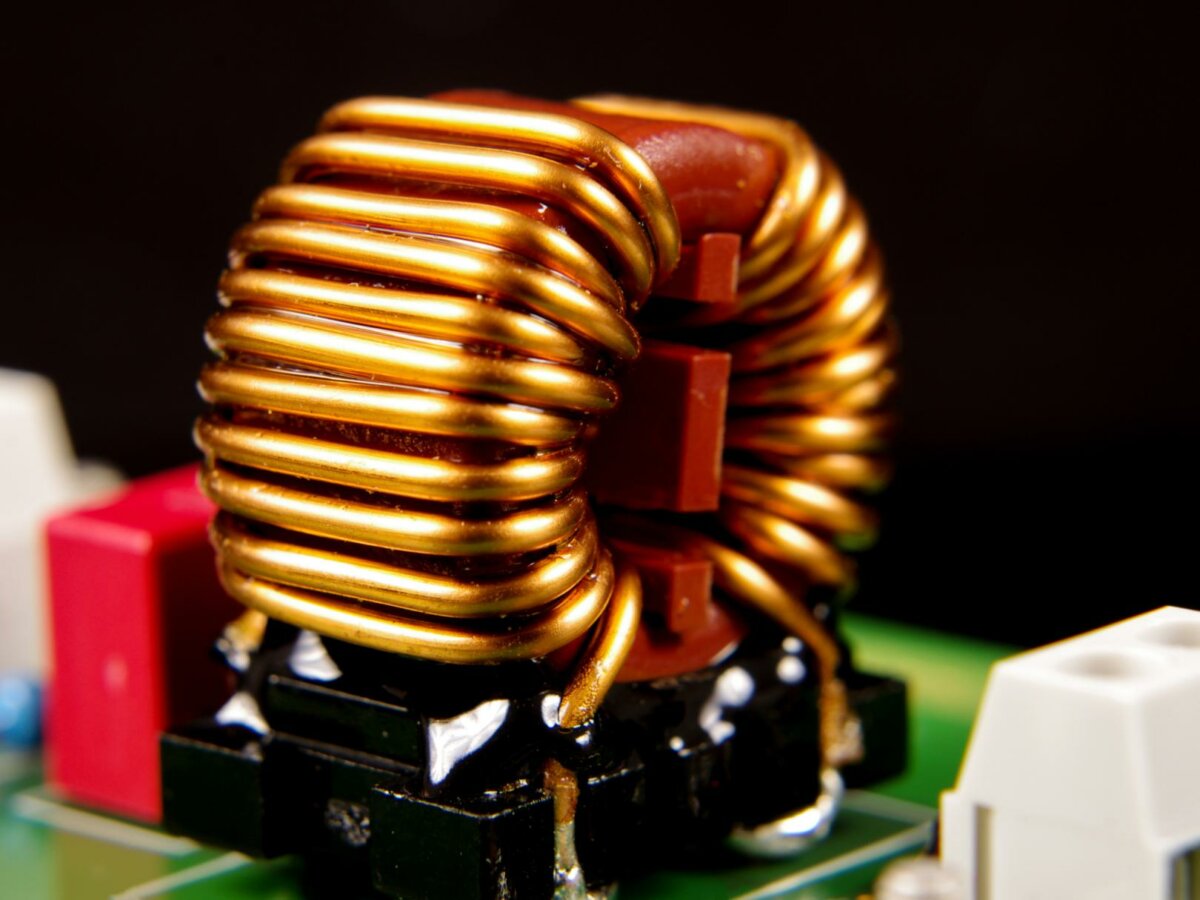

Magnetic components are energy-storage and energy-transfer parts built around soft-magnetic cores and wound conductors; typical examples include chokes, inductors, and transformers. In power electronics they manage EMC, shape current, provide isolation, or sense current in applications from AC/DC supplies and motor drives to EV charging and renewable energy systems. Our portfolio spans common-mode chokes, magnetic inductors, and multiple transformer types across frequencies from mains up to high-frequency switch-mode designs.

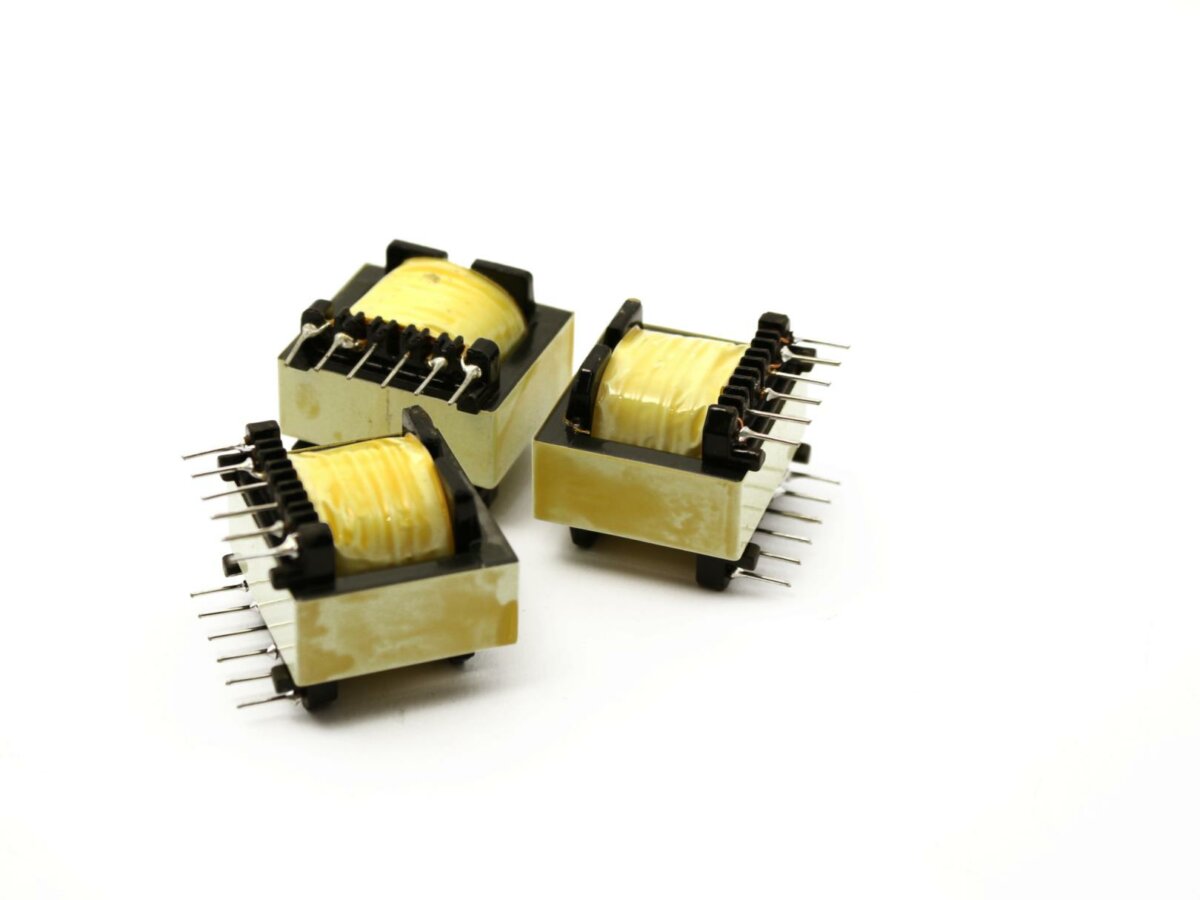

Standard magnetic components are pre-engineered parts (for example catalog inductors, EMI filters, or laminated transformers) that fit common electrical and mechanical envelopes and can accelerate time-to-prototype. Custom magnetic components are designed from first principles—core material, geometry, turns, gap, bobbin, insulation system, thermal path, and terminations—to meet a specific topology, frequency, current ripple, isolation, and form-factor target that standard parts cannot achieve. We provide both options across chokes, inductors, and transformers.

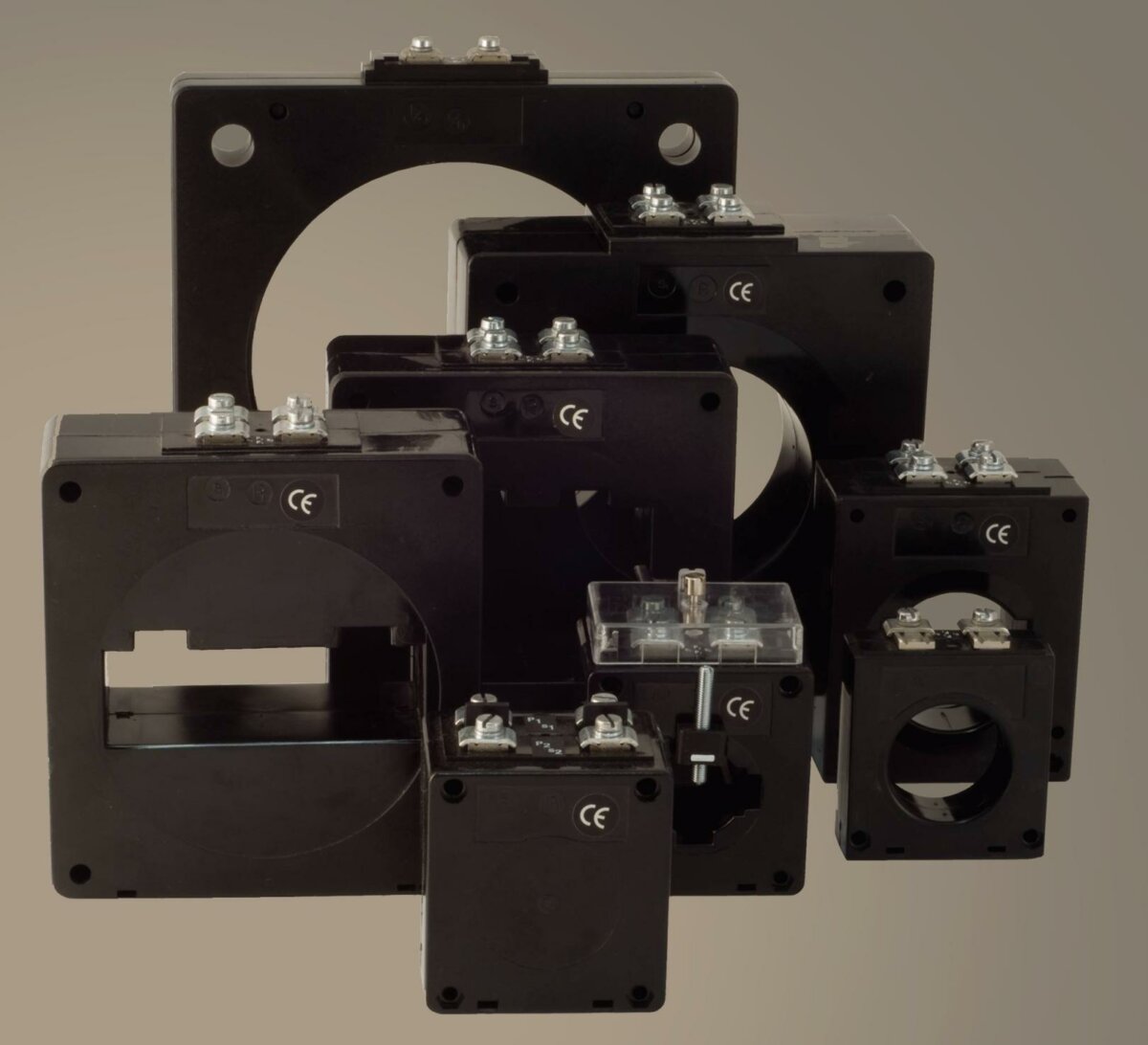

Common-mode chokes (CMC) attenuate common-mode noise on power or data lines using coupled windings on a high-permeability core (ferrite or nanocrystalline), presenting high impedance to noise while passing differential signals and DC. They are used on AC inputs, DC buses, CAN and other differential lines to meet conducted-emission limits without distorting the wanted signal. We offer standard and customised CMC designs covering single- and three-phase systems.

This term includes low-frequency laminated transformers (encapsulated PCB types, toroidal units, and larger EI single-/three-phase designs) as well as high-frequency switch-mode transformers matched to specific controller topologies. We also supply current transformers for accurate AC measurement and protection. Each class is engineered for the appropriate frequency, core material, insulation system, and thermal profile.

Efficiency is driven by core selection (ferrite vs. nanocrystalline vs. laminated steel), operating flux density, winding strategy (Litz wire, foil, interleaving), gap design, and leakage/control of AC resistance. For example, nanocrystalline cores in CMCs reduce losses while maintaining impedance; optimised switch-mode transformer winding stacks minimise copper and proximity losses at higher kHz ranges. Our design support balances these trade-offs against thermal limits and EMI targets.

Our magnetics components portfolio spans common-mode chokes, magnetic inductors (from RF chip to high-power toroids and custom assemblies), EMI filters, low-frequency laminated chokes/transformers, current transformers, and switch-mode transformers. This breadth lets us solve EMC, isolation, energy storage, sensing, and filtering tasks within one coordinated design.

Magnetics technology underpins both the reactive elements inside EMI filters and the discrete chokes that block common-mode and differential-mode noise. By pairing the right cores and winding strategies with capacitive elements and layout rules, we can meet CISPR/EN emission limits while keeping efficiency and thermal headroom. Our EMI filter ranges integrate inductors and capacitors in metal housings to simplify compliance and installation.

Yes—our Magnetics Products Technology Centre designs and manufactures custom magnetic components including bespoke inductors, common-mode chokes, laminated reactors, current transformers, and switch-mode transformers. The team collaborates on topology selection, material choice, thermal modelling, creepage/clearance, safety approvals, and DFM, serving sectors like renewable energy, EV charging, UPS, welding, drives, rail, medical, aerospace, and marine.

Provide the electrical spec (topology, Vin/Vout, frequency, power, ripple, target inductance/impedance, isolation class), thermal and ambient limits, EMI goals, safety standards, mechanical constraints (max height/footprint, terminals), and expected production volume. With this, our Magnetic Products Technology Centre can propose a core geometry, material, winding arrangement, insulation system, and verification plan, then prototype and characterise to your targets.

es. We co-engineer switch-mode transformers to match controller frequency, duty cycle, reset method, and leakage requirements, often working directly with semiconductor application engineers. This ensures the transformer meets efficiency, regulation, and transient criteria in the real topology—not just on paper—and that insulation and creepage/clearance meet the target safety standard.