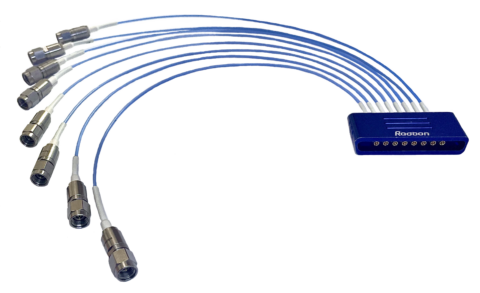

Customised cable harnesses and e-mech assemblies

- Technology

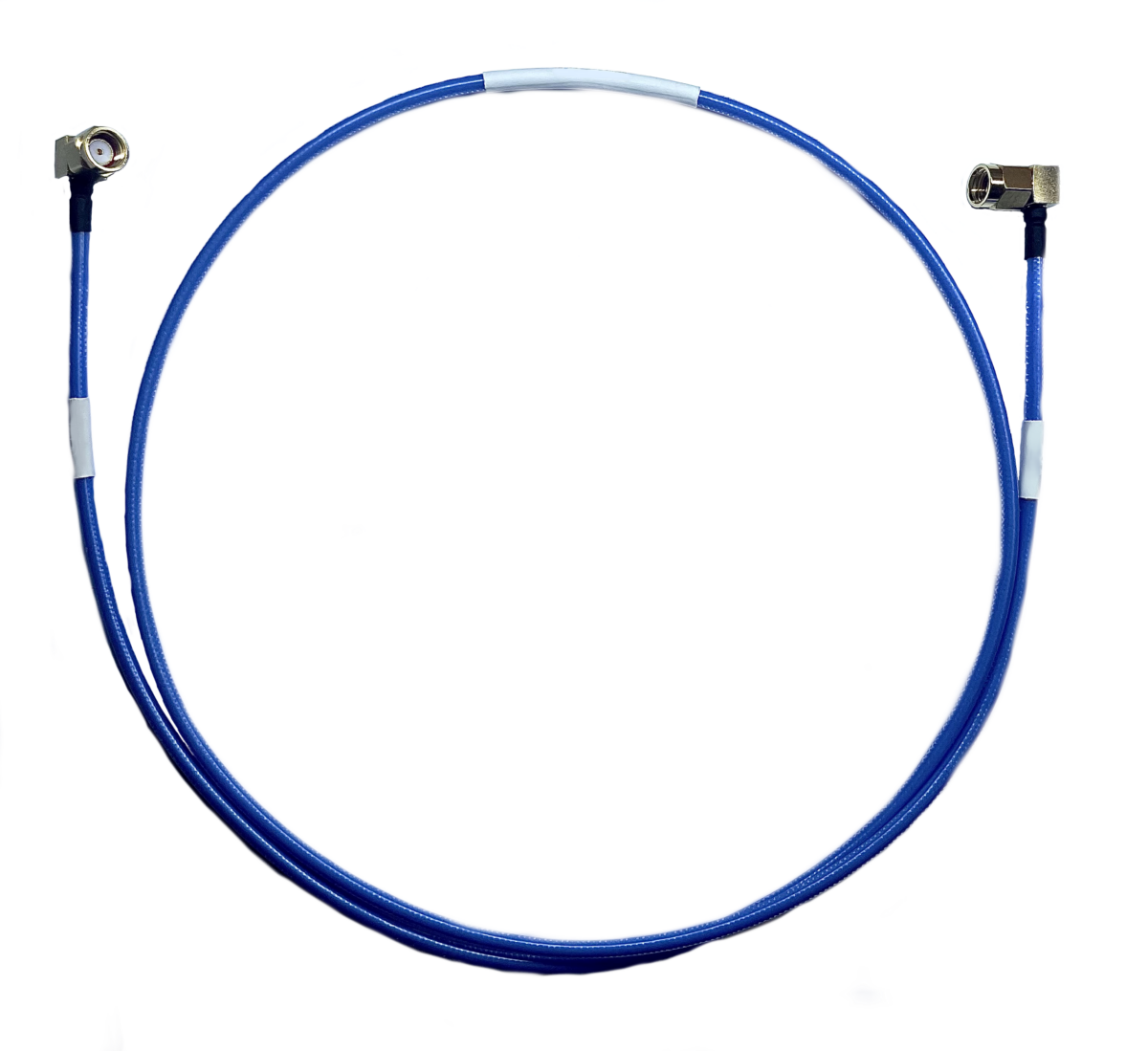

- Coaxial cable interconnect

- Partner

- Radbon

Radbon specialises in providing customised cable harnesses and electromechanical (e-mech) assemblies tailored for harsh environments, such as those found in aviation, marine, and defense industries. These products are engineered to meet the demanding requirements of these sectors, where reliability, durability, and performance are critical.

Radbons harnesses are engineered for high reliability, reducing the risk of failure in critical systems. This is vital in industries where downtime or malfunctions can have serious consequences.

The customised design ensures that each harness is perfectly suited to its application, optimising performance and efficiency in systems where precision is key. The use of advanced materials and shielding ensures minimal signal loss and interference, enhancing overall system performance.

Built to last in extreme environments, from the high altitudes and temperature variations of aviation to the corrosive saltwater conditions of marine applications. Their robust construction minimises maintenance needs and extends the lifecycle of the systems they are integrated into.

-

Aviation: Used in aircraft for wiring systems, control panels, and avionics integration, where reliability and weight reduction are critical.

-

Marine: Employed in ships and submarines for navigation systems, communication equipment, and power distribution, designed to withstand harsh marine environments.

-

Defense: Utilised in military vehicles, radar systems, and command centres, where durability, reliability, and compliance with military standards are essential.

-

Industrial and Commercial: Adapted for use in industrial machinery and commercial vehicles that operate in extreme conditions.

-

Tailored Design: fully customised cable harnesses designed to meet specific application requirements, including complex routing and integration with various systems. Each harness is designed with precise specifications for length, connector types, shielding, and wire gauge.

-

High-Quality Materials: The harnesses are constructed using high-grade materials such as Teflon, silicone, and other advanced polymers that resist environmental stressors like moisture, chemicals, and extreme temperatures. These materials ensure longevity and reliability, even in the most challenging conditions.

-

Advanced Shielding Techniques:advanced shielding techniques, including multi-layered braids and foil wraps, to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). This ensures the integrity of signals, critical in environments where communication and control systems are essential.

-

Rugged Construction: The cable harnesses are built to withstand mechanical stress, including vibration, shock, and abrasion, common in aviation, marine, and defense applications. They are also resistant to UV radiation, saltwater, and other corrosive elements, making them ideal for marine environments.

-

Variety of Connectors: offers a wide range of connectors that are compatible with the customized harnesses, including military-grade and aviation-certified connectors. These connectors ensure secure connections and reliable performance in harsh conditions.

-

Compliance with Industry Standards: designed and manufactured in compliance with relevant industry standards, such as MIL-SPEC for defense, FAA regulations for aviation, and marine certifications. This ensures that the products meet the rigorous demands and safety requirements of these industries.