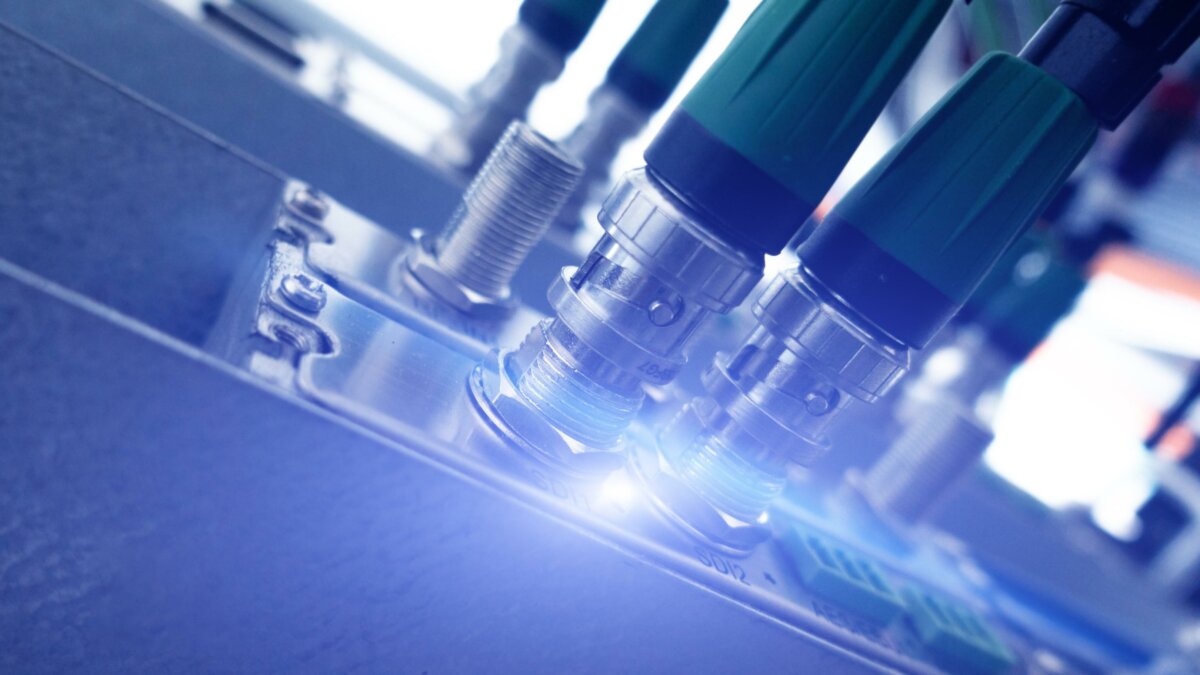

Custom cable assemblies engineered to your specification

From design to build: application-ready, fully tested interconnects—copper, fibre, hybrid and power

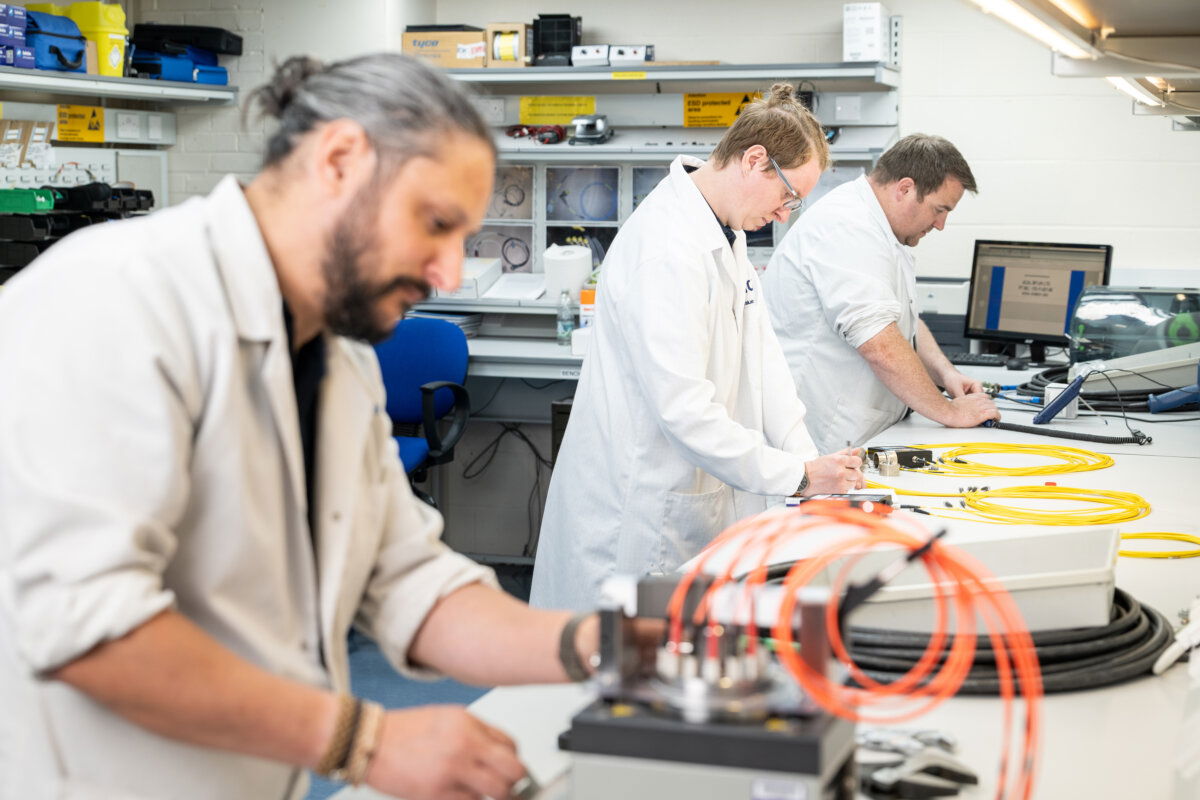

We have decades of experience in the design and manufacture of a wide range of custom cable assemblies, harnesses, and flexes.

Combined with our comprehensive portfolio of leading cable and circular connector technologies means that we deliver the best interconnect systems for your application. We assist at all stages of your project from helping you source the right components, to complete design services, all backed by our long-established expertise.

Within our Interconnect and Cable Assembly Technology Centre we have our own AS9100/ISO9001 manufacturing facilities. We can match your individual requirements and help reduce your build times and deliver an improved quality of assembly. Specialising in copper cables, fibre optic, hybrid and power cabling technology, and a wide range of manufacturing services.

Our custom cable assembly solutions provide application-ready, tested solutions that are standards-compliant. We also have in-house capability to produce options such as over-moulding, customised shielding assembly and the use of innovative wires and cables.

Other services include:

- Manufactured to your specifications – we can often source alternatives which are backwards compatible with many leading brands at a more cost-effective price, MOQ or delivery time

- We are able to design custom cables assemblies to meet the most demanding of applications

- Fully tested – all assemblies and harnesses will be tested for continuity and shorts, giving you the confidence that will enable you to install directly

- Additional testing can be done in accordance with your specific applications

- We can provide samples and demo kits, design consultancy and facilities for pre-EMC compliance testing, to accelerate and smooth your product development process

- We also offer complete maintenance and repair services, so that you know your system is in safe hands

To discuss any specific cable and connector requirements or to arrange a visit from our technical sales team, please contact us.

FAQs about our custom cable assemblies for industrial & IoT

Custom Cable Assemblies FAQs

Custom cable assemblies (and bespoke cable assemblies) are designed, built and fully tested to your specification—connector choice, shielding, over-moulding, bend-radius, labelling, and compliance—so you get application-ready interconnect cable assemblies rather than generic parts. Acal BFi’s Interconnect & Cable Assembly Technology Centre supports copper, fibre-optic, hybrid and power cabling with in-house test capability as part of its cable assembly solutions.

Yes. Acal BFi operates its own AS9100/ISO9001 manufacturing facilities, which is the quality framework many aerospace primes expect for AS9100 high performance cabling and AS9100 high performance cable harness builds. For harsh-environment and defence projects, they specify, assemble and release circular connectors to recognised military standards.

Yes—Acal BFi provides custom cable assemblies UK with UK technical contacts and AS9100/ISO9001 manufacturing behind them. Engagement typically covers consult → design → integrate, from component selection through to validated builds and documentation.

Acal BFi supplies coaxial cable interconnect options—from microminiature U.FL/MMCX up to TNC/UHF—and can build custom cable assemblies or customised hybrids (signal + coax) for outdoor and high-frequency use, including semi-rigid and ruggedised variants. This suits RF antennas, test leads and microwave links.

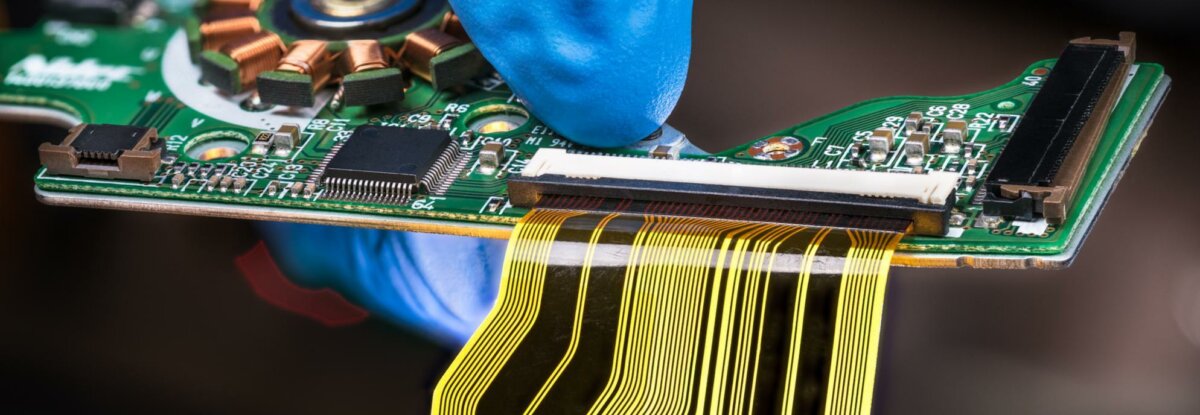

Flat ribbon cables are ideal for high density cable assembly needs where space, weight and flexibility dominate. Flexible flat cable (FFC) and flexible printed circuits (FPC) enable tight routing, controlled impedance and dynamic flex—often outperforming round cables in compact electronics—making them a strong choice from a ribbon cable assemblies manufacturer.

Over-moulded connector assemblies add strain relief, ergonomics and ingress protection (IP), improving reliability in medical, industrial and automotive environments. They combine off-the-shelf or custom connectors (e.g., Hirose, Amphenol) into a sealed, robust termination—one of the key bespoke assemblies advantages for lifecycle and field durability.

Ruggedised and harsh-environment assemblies use corrosion-resistant materials, environmental sealing (up to hermetic), vibration-resistant construction and defence-approved circular systems. This approach is proven in aerospace, marine and industrial settings where cable assemblies custom built to spec must survive extreme temperature, moisture and shock.

Yes. Smart custom cable assemblies encapsulate PCBs and active/passive components to add functions such as protection or signal conversion, reducing space and weight versus separate inline boxes—particularly attractive in medical and compact devices. This is a powerful path for custom wire assemblies and custom power cable assemblies where intelligence at the interconnect adds value.

All three. Crimping creates an air-tight metal-to-metal interface for strong, reliable joints; IDC enables fast, mass-termination of ribbon conductors without stripping; solder remains appropriate for certain connector systems and repairability. Selecting the right method is part of Acal BFi’s custom cable manufacturing and cable assembly manufacturer workflow.

Provide electrical ratings (voltage/current), conductor material (e.g., copper cable assembly), wire gauge, shielding/EMC needs, environment (IP rating, chemicals, temperature), routing/strain constraints, approvals (AS9100/ISO9001, medical, defence), connector part numbers, drawings/BoM and test requirements. With this, a custom cable assembly manufacturer can propose manufacturable designs and validated test plans for custom cable assemblies manufacturing—including special requests like high-density cable assembly, interconnect cable assemblies, or even pbof cable assembly if required.