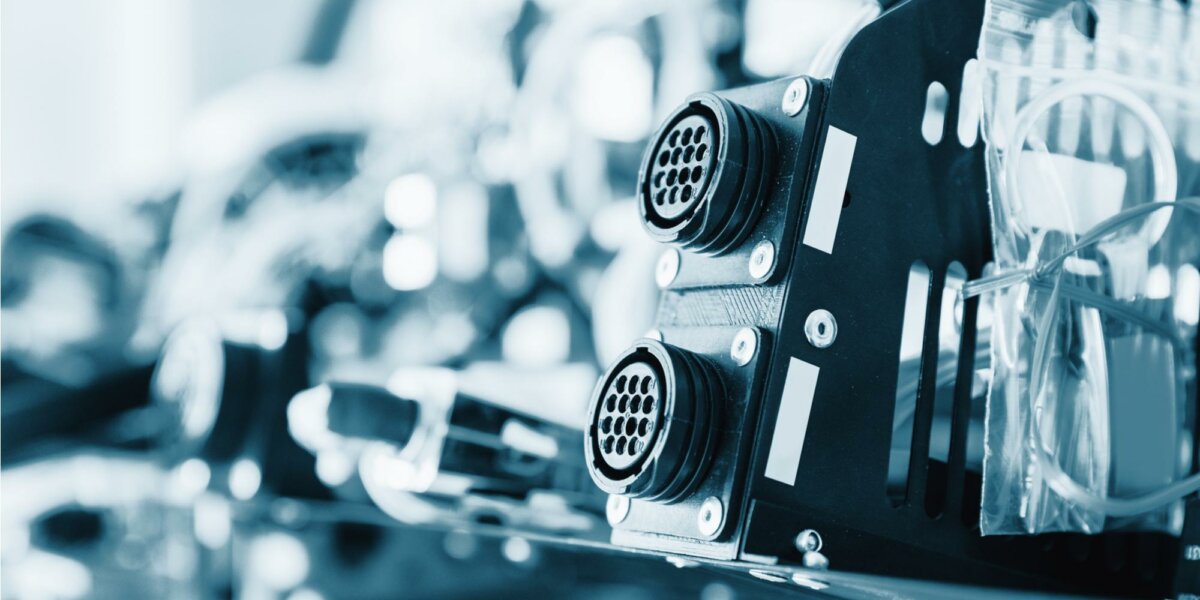

Waterproof circular connectors

For applications where exposure to fluids including moisture, rain to temporary or constant submersion are a factor there are circular power connector types that are suitable for the application.

We can offer interconnect solutions in both metal and plastic shell that enable sealing and protection against dust and fluid ingress from IP5x, IP68, IP69K and even custom hermetic products for subsea, high pressure environments.

As the specification of a fully sealed circular connector system is subject to a number of factors, we can assist with your design in specifying a suitable connector solution through to a complete lead assembly capability with technologies ranging from sealed cable gland backshells, heat shrink, wire grommets and epoxy potting through to over moulded cables.