D38999 rugged TV Connector Series MIL-DTL-38999

- Technology

- Metal circular connectors

- Partner

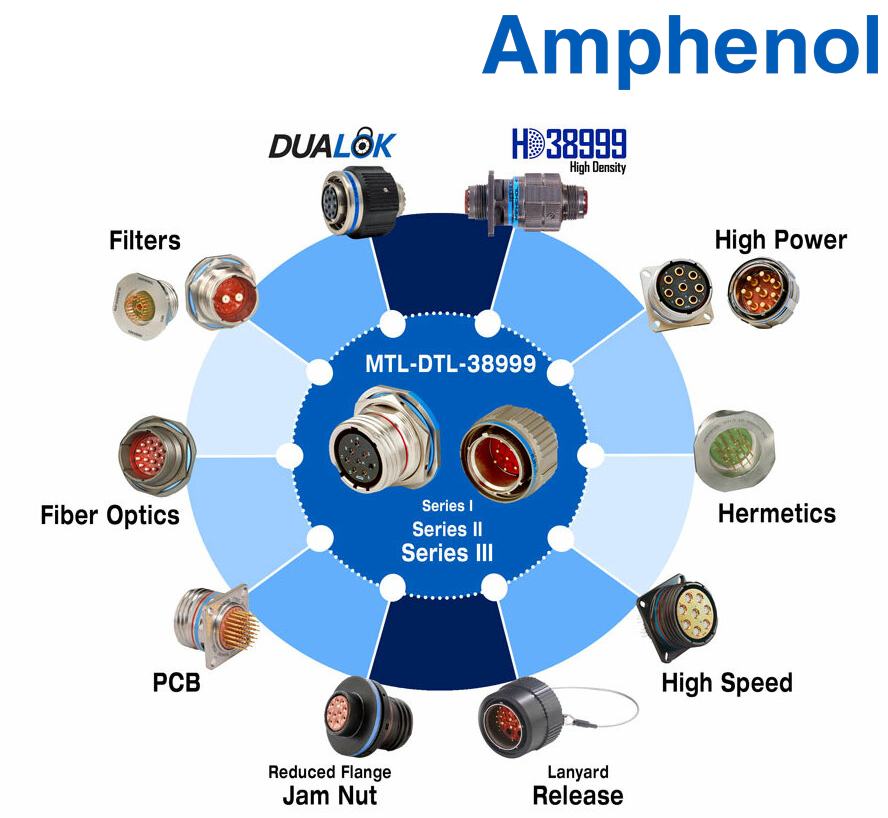

- Amphenol

Assembled at Acal BFI’s facility in the UK, is the extensive range of D38999 / TV connectors. The D38999 range is designed and approved to MIL-DTL-38999 standard and is in frequent use in military and defence applications.

The range of circular connectors features a threaded anti-vibration coupling system to the plug, with wall mount or jam nut receptacles with accessory threads to accept various backshells including the BK4 series of heat-shrink adaptors. Shells are available in various platings including QPL approved Cadmium, Electroless Nickel and Black Zinc Nickel. Olive Drab Zinc Cobalt and Bronze material shells for high salt spray corrosion resistance are available in the proprietary TV range of connectors.

Extensive connector configurations are available with contact acceptance from size 23 to size 4 power in numerous planforms suitable for signal, fibre, power, RF or a hybrid pattern.

A full cable assembly capability is offered.

Amphenol® Tri-Start MIL-DTL-38999 Series III connectors are built for reliability, whether in everyday use or in harsh environments. They meet or exceed the MIL-DTL-38999 Series III specification and are available with aluminum, stainless-steel, or composite shells in multiple finishes.

These circular connectors are a long-standing industry standard across commercial, military, and aerospace applications. The Tri-Start range supports high contact densities and rigorous performance needs, while offering shell material and finish options to match weight, corrosion, and durability requirements.

With configurations up to 128 contacts, Tri-Start Series III (TV) connectors provide a rugged interconnect for general duty and severe conditions. Designs include advanced EMI shielding, ESD protection for high-voltage/high-current events, resistance to high-temperature vibration, improved interfacial sealing for moisture resistance, and an optional hermetic version rated to 1 × 10⁻⁷ cm³/s.

Range features

A high level overview of what this range offers

- D38999 series QPL approved to MIL-DTL-38999 III

- Acal BFI is an Amphenol assembly partner with connectors produced at our facility in the UK

- Numerous planforms available with up to 128 contact positions

- High power planforms available to 100A dc

- Crimp contacts standard, with the option of custom preinstalled PCB contacts

- Thermocouple contacts available in Chromel, Alumel, Iron and Constanstan

- Numerous accessories including protection caps, strain relief and backshell kits

- RoHS compliant platings including black zinc nickel, electroless nickel and olive drab zinc cobalt

- Full customisation and cable assembly facility available

Product Options

Shell styles

- Wall-mount, jam-nut, straight cable plug, in-line receptacle, box-mount, and flange-mounting options.

- Nine standard shell sizes (9, 11, 13, 15, 17, 19, 21, 23, 25) and three XL non-standard sizes (25, 33, 37).

Contact types

- Crimp, solder, PCB, wire-wrap, coax, twinax, triax, thermocouple, fiber-optic termini, and more.

Plating / finishes

- Cadmium over nickel, electroless nickel, stainless steel, black zinc-nickel, and additional finishes on request.

Accessories

- Endbells, cable clamps, dust caps, and sealing plugs to enhance strain relief, protection, and sealing.

Downloads

for D38999 rugged TV Connector Series MIL-DTL-38999

Technical Specifications of the D38999 rugged TV Connector Series MIL-DTL-38999

Electrical

Suggested operating voltage:

- Service M: 400 VAC (RMS), 500 VDC

- Service N: 300 VAC (RMS), 450 VDC

- Service I: 600 VAC (RMS), 850 VDC

- Service II: 900 VAC (RMS), 1250 VDC

Current rating: up to 150 A test current with size-0 crimp contacts.

Mechanical

- Durability: minimum 500 mating cycles.

- Shell materials: aluminum alloy, stainless steel, composite, or nickel-aluminium bronze (marine-grade).

- Finish options include (among others):

- Olive-drab chromate over cadmium over electroless nickel (per QQ-P-416)

- Olive-drab cadmium plate (per QQ-P-416)

- Conductive corrosion-resistant steel (passivated)

- Nickel-aluminium bronze

- Durmalon™

- Conductive electroless nickel -Electrodeposited nickel (per QQ-N-290)

- Olive-drab zinc-cobalt -Black zinc-nickel

Environmental

-Operating temperature: −65 °C (−85 °F) to +200 °C (+392 °F). -Salt-spray resistance: minimum 500 hours.

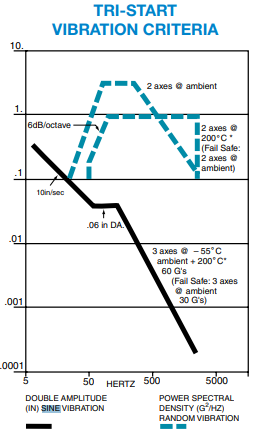

Vibration & Shock

-Designed for high-temperature vibration environments; tested to relevant MIL-DTL-38999 Series III requirements.

FAQs

for D38999 rugged TV Connector Series MIL-DTL-38999

D38999 is a family of high-reliability circular connectors defined by MIL-DTL-38999, commonly used in aerospace, defence and industrial systems. Amphenol covers Series I (JT), Series II (LJT), Series III (TV/SJT) and hermetic variants, with multiple shell styles (e.g., wall, box, jam-nut, straight plug).

Typical service ratings include M, N, I and II, with suggested operating voltages such as 400 V AC (M), 300 V AC (N), 600 V AC (I) and 900 V AC (II), and corresponding test voltages per altitude. Designers should apply appropriate safety factors for surges/transients.

D38999 shells are offered in aluminium, stainless steel, titanium, composite and nickel-aluminium bronze, with finishes such as olive-drab cadmium, electroless nickel and RoHS black zinc-nickel—selected to optimise corrosion resistance, conductivity and weight for your D38999 installation.

D38999 families typically operate from around –65 °C up to +175 / +200 °C (finish-dependent), meet environmental sealing requirements of MIL-DTL-38999, and provide salt-spray resistance per plating type—helping your D38999 interface survive extremes of temperature, fluids and humidity.

D38999 supports multiple insert arrangements with contact sizes from signal (#22D/#20) to power (#12/#8/#4). Depending on size and wiring, D38999 power contacts can be specified for tens of amps up to high-current duties, with crimp, solder or busbar options to suit your load and derating policy.

When paired with appropriate EMI backshells, braid terminations and 360° shielding, D38999 achieves high shielding effectiveness across RF and microwave bands, meeting stringent aerospace/defence EMC requirements while maintaining the environmental sealing of the D38999 interface.

The D38999 ecosystem includes environmental and EMI backshells (straight/45°/90°), protective caps, lanyards, sealing gaskets, as well as signal, power, coax and twinax contacts. Qualified crimp tools, positioners and insertion/extraction tools are specified by D38999 contact size and serie

Yes. We engineer D38999 selections for the harshest environments—matching shell material, plating, insert layout and accessories to your platform and compliance needs. We also offer, exclusively via Acal BFi, Amphenol’s 602 GB D38999 version; contact us for technical guidance and availability.

Yes. D38999 supports high-speed through dedicated contact systems—coax, twinax and quadrax—for protocols such as 100/1000BASE-T, 10G (with suitable inserts), USB, and SDI/HD-SDI. Use impedance-controlled contacts (often size 8/10), short shield paths, and EMI backshells to manage return loss, crosstalk and eye-diagram margins.

Define the series (I/II/III), shell style (plug, wall, jam-nut, box), shell size, insert arrangement, keying/polarisation (rotation), material and plating (e.g., cadmium, electroless nickel, black Zn-Ni), contact type/termination (signal, power, coax/twinax/quadrax; crimp/solder), and any accessories (backshells, boots, caps). Acal BFi can create the D38999 bill-of-materials, advise on RoHS/REACH options, and cross-reference Amphenol’s 602 GB variant where appropriate