C300 high speed laser illumination welding camera

- Technology

- High-speed laser illumination

- Partner

- Cavitar

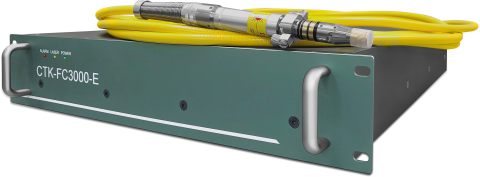

With an integrated pulsed diode laser, the compact C300 camera allows insights into welding processes that could not be achieved with other methods until now. The laser pulses generated at the same rate as the frame rate brighten the welding process and its immediate surroundings to such an extent that the film recordings show high contrasts, and many details can be made visible.

For all welding processes such as MAG, MIG, TIG, CO2, fibre laser, diode laser, ND:YAG and electron beam welding, the use of the C300 camera is of great benefit. Thanks to the class 3R laser used, this camera is eye-safe and can be operated without protective goggles. For the user, the advantages of this C300 welding camera are obvious: it enables tireless visual process monitoring, improved ergonomics and minimal exposure to process gases and UV radiation. The complete package of the C300 welding camera consists of the camera head with exchangeable protective glass, power supply unit and control or film recording software.

Range features

A high level overview of what this range offers

-

High contrast image quality and the ability to simultaneously measure

- Position, dimensions and shape

- Topography

- Micro and macro defects

-

Compact design and GigE data connection

-

Compact design and GigE data connection

-

1440×1080 pixels, 1.55 megapixel resolution and up to 60 frames/sec

-

Easily exchangeable protective windows

-

42×32 mm field of view at 200 mm working distance. Different working distances are optionally adjustable and available

-

Ergonomic operation without exposure to process gases and UV radiation

Downloads

for C300 high speed laser illumination welding camera

| Model | Resolution | Max frame rate | Data transfer | Software | Dimensions | Applications |

|---|---|---|---|---|---|---|

C300 Welding camera | 1440 x 1080 pixel | 70 fps | GigE | Cavilux | 30 x 45 x 99 mm without plug | MAG, MIG, TIG, CO2, fibre laser, diode laser, Nd:YAG, electron beam welding |

C350 Welding camera | 1440 x 1080 pixel | USB3 | Cavilux | 30 x 45 x 99 mm without plug | MAG, MIG, TIG, CO2, fibre laser, diode laser, Nd:YAG, electron beam welding | |

C400-H Welding camera | 1440 x 1080 pixel | 70 fps | GigE including temperature monitor | Cavilux | 30 x 45 x 99 mm without plug | MAG, MIG, TIG, CO2, fibre laser, diode laser, Nd:YAG, electron beam welding |

FAQs

for C300 high speed laser illumination welding camera

Welding cameras are used in industry to monitor and document welding processes in real-time. They help to check the quality of welding and to detect any errors or anomalies early on. This can prevent potential failures and costly repairs.

A high-quality welding camera should offer high contrast and detail accuracy to clearly represent the welding process. It should be robust and heat-resistant to withstand the harsh conditions in industrial environments. Additionally, it should be as compact and ergonomic as possible to allow for easy handling and installation.

Welding cameras enable remote monitoring of welding processes, meaning that workers do not need to be physically close to the welding area. This reduces the risk of injuries from sparks, UV radiation, or process gases.

Lighting is an important aspect of welding cameras, as it enhances the visibility and detail accuracy of the recordings. Laser lighting units are particularly effective as they provide bright, high-contrast images and can make many details visible.

Monitoring welding processes with cameras provides valuable data about the process that can be used for analysis and optimisation. For example, parameters such as welding speed, temperature, wire feed, and weld seam geometry can be monitored and adjusted to improve product quality and increase efficiency.

Integrating welding cameras into existing production lines can vary in complexity depending on the requirements and environment. Challenges may include the placement and alignment of the camera, integration into the existing control system, or adjusting the lighting.

Operating welding cameras requires an understanding of the welding processes and the specific parameters that need to be monitored. In addition, knowledge of image processing and analysis is helpful for effectively utilising the captured data. It is recommended that users receive appropriate training from the manufacturer or a qualified provider.