Thermography Cameras, Thermal Imagers & Systems

- Technology

- Automated infrared imaging cameras

- Partner

- Advanced Energy

Advanced Energy’s turn-key thermal infrared imagers and systems accurately measure temperature accurately using ultra-reliable infrared technology. These high-tech instruments can precisely determine the temperature and temperature distribution of small and fast-moving objects.either inside an industrial process (inside a boiler or furnace) or remotely (monitoring a flame from distance).

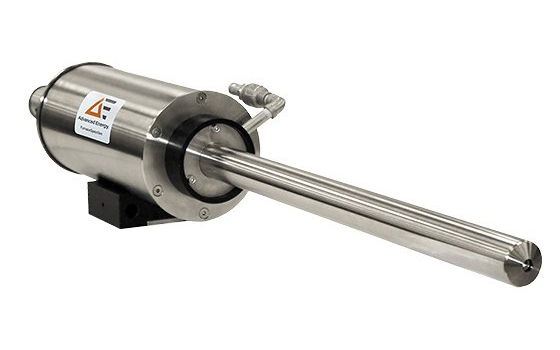

The BoilerSpection SD imaging system is a turnkey solution for continuous infrared imaging inside boilers and furnaces. This system provides continuous, real-time, through-flame imaging inside boilers and allows to optimise the combustion by tracking uniformity of ash deposits.

The FurnaceSpection is an infrared camera system for continuous reformer tube monitoring and temperature measurement inside furnaces. It provides real-time continuous temperature measurement to identify process abnormalities inside high-temperature furnaces in refining, metals, and glass production processes. It measures the temperature of product, refractory, and heat transfer surfaces inside natural gas-fired furnaces.

The FlareSpection is an infrared camera system for continuous pilot flame and flare stack. The FlareSpection provides extremely clear and reliable flare image and pilot flame monitoring of multiple flare tips. It continuously monitors through moisture, heavy rain, and fog from hundreds of metres away. Its certified explosion-proof housing enables the system to be in hazardous areas. You can also confirm pilot flame and flare presence, detect plant performance deviations, and set alarms using the system’s advanced software.

What’s in this range?

All the variants in the range and a comparison of what they offer

| Camera Model | BoilerSpection SD | FurnaceSpection SD | FurnaceSpection | ThermalSpection |

|---|---|---|---|---|

Type | Infrared imaging camera with a cooled borescope lens | Infrared imaging camera with a cooled borescope lens | Infrared camera with borescope lens for high-temp furnaces | Panoramic thermal imaging camera for substation monitoring |

Measurement Range | 500 – 1600°C | 600 – 1800°C or 800 – 2200°C (water-cooled only) | 600 – 1800°C | -40 to 370°C |

Filter | Narrowband 3.9µm | Narrowband 0.85μm | Narrowband 0.85μm | LWIR (long-wave infrared, 8–14 μm) |

Detector & Optics | 320 x 240 uncooled microbolometer, 50° x 38° FOV | 640 x 480 silicon-based, 55° x 41° or 72° x 54° FOV | 640 x 480 silicon-based, 55° x 41° FOV | 640 x 480 uncooled microbolometer, wide FOV |

Construction | Stainless steel IP66, air cooling & purge | Stainless steel, air or water cooling | Stainless steel, water-cooled | Outdoor-rated enclosure with climate control |

Unique Feature | Automatic retraction system | Automatic retraction system | Auto-retraction on temperature spike | AI-based fault detection and thermal trending |

Camera Interface | 100 Base-T Ethernet, multi-mode fibre | 1000 Base-T Ethernet (GigE), multi/single-mode fibre | GigE, fibre optic support | Ethernet, cloud & SCADA integration |