Etherstax series signal conditioners

- Technology

- Industrial I/O Modules & Embedded Interfaces

- Partner

- Acromag

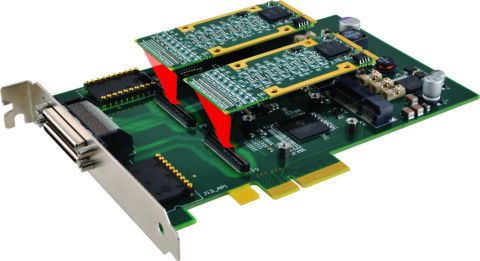

The EtherStax series Ethernet I/O modules provide a powerful solution for connecting extensive field I/O to Ethernet-based automation systems. Each compact unit can handle dozens of sensor inputs or actuator outputs – up to 96 channels of discrete signals or 64 analogue signals on a single module – significantly reducing the hardware footprint. Built for industrial use, EtherStax blocks feature a ruggedised aluminium enclosure, wide -40 to 70°C operating range, and compliance with Class I Division 2 hazardous location standards for dependable service in harsh environments.

Dual networking ports (copper and optional fibre) with automatic failover ensure redundant communication paths, while dual power inputs keep the unit alive through power source interruptions. These high-speed I/O conditioners can scan or update all channels in mere milliseconds, making them ideal for real-time monitoring and control tasks. Engineers can easily configure and monitor each module via a built-in web interface, without special software, enabling quick setup and integration into SCADA, PLC or DCS systems. From remote substation monitoring to factory floor automation, EtherStax modules excel in delivering reliable, high-density I/O connectivity in demanding applications.

Range features

A high level overview of what this range offers

- High channel density – Accommodates up to 96 I/O channels on one module, saving panel space and minimising the number of devices needed in large systems.

- Stackable rugged design – Sturdy aluminium housing and interlocking form factor let units stack vertically in a small footprint, withstanding shock, vibration, and extreme temperatures for dependable field use.

- Dual Ethernet ports (copper/fibre) – Redundant network interfaces support daisy-chaining or ring topologies (STP/RSTP), ensuring uninterrupted communication even if one link fails.

- Dual power inputs – Redundant DC power feeds provide fail-safe operation; the module continues running seamlessly on the backup supply if the primary power source is lost.

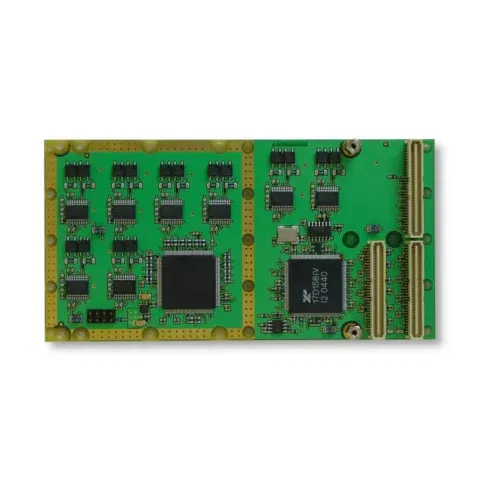

- High-speed updates – Fast 16-bit A/D and D/A converters and efficient design enable scanning of all inputs or refreshing of all outputs in under 10 milliseconds, supporting real-time control and data acquisition.

- Isolation and surge protection – 3-way or 4-way isolation (I/O, power, network, and channel-to-channel) plus built-in surge suppression safeguard the system from transients, prevent ground loops, and improve signal integrity.

- Web-based configuration – Integrated web server interface allows easy module setup, calibration, and diagnostics through any web browser, simplifying commissioning without special software.

- Peer-to-peer i2o® communication – Input changes can be transmitted directly to output modules over the network with minimal latency, enabling real-time mirroring of signals and distributed control logic independent of the central PLC/SCADA.

- Flexible I/O interfacing – Analogue models accept a variety of sensor signals (voltage, current, etc.), including an option to use 8B isolation amplifier backplanes for thermocouples, RTDs, load cells and more. Digital models offer bi-directional channels and support mixed input/output configurations, including high-voltage relay outputs for driving loads.

- Failsafe and diagnostics – Integrated watchdog timers and a fault relay output allow automatic safety actions (e.g. set outputs to a safe state or trigger an alarm) on communication loss or power failure, enhancing overall system safety.

What’s in this range?

All the variants in the range and a comparison of what they offer

| Model | I/O Type | Channels | Signal Type / Range | Communication | Isolation | Update / Scan | Key Features |

|---|---|---|---|---|---|---|---|

ES2113 | Discrete I/O | 96 bi-directional | Digital, 0–28 V DC logic | Modbus TCP/IP, UDP/IP, i2o | Standard industrial | ~1 ms full update | High-density stackable; change-of-state; watchdog & failsafe; loop-back monitoring |

ES2117 | Discrete I/O | 48 total (32 inputs, 16 outputs) | Isolated digital; inputs (AC/DC), outputs via 2 A relays | Modbus TCP/IP, UDP/IP, i2o | Full isolation between circuits | <10 ms peer-to-peer | Fully isolated; heavy-duty SPST relays; local alarm; logic inversion for i2o |

ES2162 | Analog Input | 32 differential | Voltage analog inputs | Modbus TCP/IP, UDP/IP, i2o | 4-way isolation & surge suppression | Up to 1 kHz scanning | Dual DB25 ports for 8B interface; 16-bit A/D; browser config; scaling/integration functions |

ES2163 | Analog Input | 64 single-ended | Current analog inputs (±20 mA, 0–20 mA, 4–20 mA) | Modbus TCP/IP, UDP/IP, i2o | 4-way isolation & surge suppression | ~10 ms update (all) | 16-bit A/D; zero/span auto-cal; sample averaging; browser config |

ES2164 | Analog Input | 64 single-ended | Voltage analog inputs | Modbus TCP/IP, UDP/IP, i2o | 4-way isolation & surge suppression | ~10 ms update (all) | 16-bit A/D; auto-zero/span cal; sample averaging |

ES2171 | Analog Output | 16 | Current analog outputs | Modbus TCP/IP, UDP/IP, i2o | 3-way isolation & surge suppression | <1 ms per channel | High-res (16-bit D/A); loop-back verify; self-test; browser config |

ES2172 | Analog Output | 16 | Voltage analog outputs | Modbus TCP/IP, UDP/IP, i2o | 3-way isolation & surge suppression | <1 ms per channel | High-res (16-bit D/A); loop-back verify; self-test; browser config |

FAQs

for Etherstax series signal conditioners

Each EtherStax module offers a very high channel count in a single unit. Digital I/O models provide up to 96 discrete channels, which can be configured as inputs or outputs in various combinations. Analogue models support as many as 32 differential or 64 single-ended channels for analog signals. This flexibility means a single EtherStax block can interface dozens of sensors (voltage, current, temperature, etc.) or control points, greatly simplifying system architecture in large-scale installations.

EtherStax modules communicate primarily using standard industrial Ethernet protocols. They support Modbus TCP/IP and UDP/IP for straightforward integration with SCADA, PLCs, and DCS systems. In addition, they feature dual 10/100 Ethernet ports (with models offering copper and/or fibre connections) that can be used for network redundancy or daisy-chaining multiple units. The dual-port design supports networking features like Spanning Tree Protocol (STP/RSTP) to provide bumpless failover if one link goes down. This ensures continuous communication without interrupting control data flow.

Dual Ethernet ports on EtherStax modules allow two independent network connections. In a critical application, you can connect one port to a primary network switch and the second to a backup or to a ring network topology. If the primary link fails, the module automatically switches to the secondary link, maintaining communication. Similarly, dual power inputs enable two separate DC supply sources to power the unit. If one power source is lost or turned off, the EtherStax unit seamlessly continues running on the second supply. Together, these features provide highly reliable, fault-tolerant operation ideal for mission-critical systems that cannot afford downtime.

Yes – the EtherStax series is purpose-built for demanding conditions. The modules are housed in durable aluminium enclosures and are engineered to withstand shock and vibration, which is important for on-machine or outdoor installations. They operate over a wide temperature range from -40°C to +70°C, so extreme heat or cold is not an issue. They are also rated for Class I, Division 2 hazardous locations, meaning they can be safely used in environments with flammable gases or vapours (such as oil and gas facilities or chemical plants). These qualities ensure EtherStax units deliver dependable performance even in harsh industrial or remote environments.

Configuration of EtherStax modules is straightforward and does not require proprietary software. Each module includes an embedded web server – you simply connect a PC (or any device with a web browser) to the module’s network and access the configuration interface through the browser. From there, you can set up IP addresses, configure I/O channel parameters (such as input ranges, output ranges, calibration, scaling), and assign peer-to-peer links using i2o if needed. The web interface is user-friendly, providing convenient monitoring of I/O status as well. This makes commissioning new modules or adjusting settings in the field quick and convenient for engineers and technicians.

i2o (which stands for “input-to-output”) is a peer-to-peer communication technology supported by EtherStax modules. It allows modules to talk directly to each other over the Ethernet network without requiring commands from a master controller for every exchange. For example, an EtherStax input module detecting a change on a sensor can automatically send that value to an EtherStax output module elsewhere, which then drives an actuator in near real-time. This is highly useful for mirroring signals or creating interlocks and alarm triggers across distributed I/O points. The updates are event-driven and very fast (on the order of milliseconds between units), improving response time and offloading work from the central PLC or SCADA system in distributed control applications.

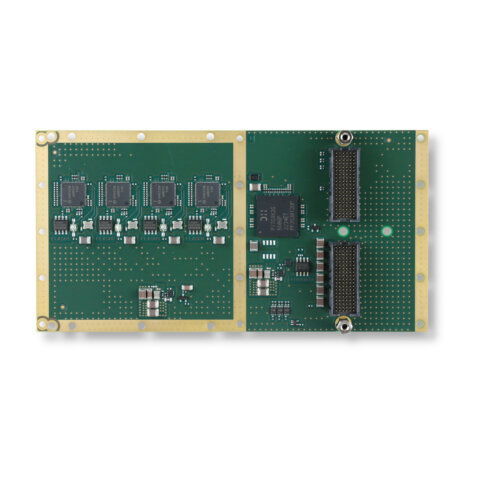

The EtherStax analogue input units are designed with high signal integrity in mind. The standard design already uses differential analog inputs (for models like the 32-channel ES2161/ES2162), which inherently helps reject common-mode noise and avoid ground loop issues between channels. Additionally, these modules provide up to 4-way isolation – isolating the input circuits from the output, power, and network circuits. For applications requiring per-channel isolation or handling multiple sensor types, EtherStax offers an option to interface with industry-standard 8B signal conditioning backplanes. This allows you to add isolated signal conditioner modules (for thermocouples, RTDs, strain gauges, etc.) on a per-channel basis. In summary, EtherStax analog inputs are well-equipped to deal with grounding issues and maintain accuracy by design, and they offer further isolation expansion options when needed.

EtherStax modules are built for high-speed I/O performance. The analogue models feature 16-bit A/D converters that can scan all channels at rates up to 1 kHz (one thousand readings per second for each channel). In practical terms, an EtherStax analog input unit can acquire all 32 channels in under 2 milliseconds in certain modes. For analogue output units, updates to all outputs can occur in just a few milliseconds as well (for example, update all 16 outputs in under 4 ms). The digital I/O models likewise support very fast state changes; they can detect an input change and have a corresponding output react on a peer module in under 5 milliseconds using i2o. This kind of speed is more than sufficient for most real-time control and monitoring tasks in industry, including high-speed interlocking, process control loops, or even certain motion control and protective tripping applications. It ensures that using EtherStax I/O will not be the bottleneck in a responsive control system.

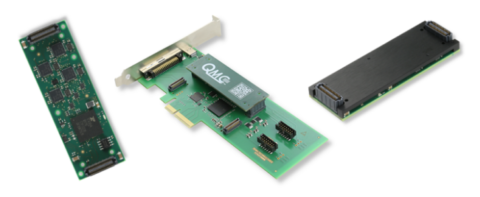

EtherStax modules have a unique stackable form factor. In practice, this means you can directly stack multiple units vertically, interlocking them to create a high-density tower of I/O that’s very stable. The footprint of each module is roughly 9 by 7 inches, so even a stack consumes minimal panel space. For mounting, there are accessories available: for example, a 19-inch rack mount kit with a built-in DIN rail (Part 20RM-16-DIN) can accommodate EtherStax modules for rack installation. Additionally, there is an open board mounting kit (ESA-OMK) for the board-level versions of EtherStax if you intend to integrate them into your own enclosure or equipment. In summary, you can mount EtherStax units on panels, DIN rails (with the rack-mount kit), or even directly on machinery – their shock-resistant design allows close-to-machine mounting, and the flexible mounting accessories make it easy to fit them into your preferred setup.

EtherStax modules include several diagnostic and fail-safe features to enhance system reliability. Each unit has self-test routines – for instance, analogue output models include a loop-back circuit to verify output channel functionality and on-demand self-calibration checks. All modules have watchdog timers: if communications from the host or peer are lost for a defined interval, the watchdog can either put output channels into a safe predefined state or hold their last value, as per your configuration. Additionally, there is a dedicated fault relay contact on the unit which will energise or de-energise to signal a fault condition (such as loss of comms or power). This relay output can be wired to an alarm or safety system for immediate notification or shutdown actions. These built-in features mean that if something goes wrong – a network cable gets cut, or a power supply fails – the EtherStax will not only try to stay running on its redundant features, but also alert your system and default outputs to safe conditions to prevent uncontrolled states.