Modular measuring devices for Section 14a EnWG: Intelligent solutions for municipal utilities and energy suppliers

Modular power measurement devices

Rising loads due to e-mobility, heat pumps, and decentralised power generation are placing new demands on low-voltage networks. With the amendment of Section 14a EnWG, network operators are now required to detect critical grid conditions at an early stage and implement targeted control measures. A reliable measurement infrastructure is therefore essential – especially in existing transformer stations.

Our modular retrofit measurement systems make this possible: they provide precise, feeder-specific acquisition of all relevant grid parameters – directly within the transformer station. And all of this without extensive modifications or costly full-scale refurbishments.

The challenge of section 14a EnWG – what is required?

What is behind section 14a EnWG?

Section 14a of the German Energy Industry Act requires distribution network operators to manage controllable consumption devices – such as EV charging stations, heat pumps or battery storage systems – in a grid-supportive way. The prerequisite for this is real-time determination of the network status.

In plain terms:

Feeder-specific measurement data must be available within 5 minutes in order to detect, document and control a grid-critical situation.

Why is retrofitting necessary?

Many local substations in Germany were built decades ago – without modern metering infrastructure.

However, today’s reality looks different:

- New regulatory requirements

- Decentralised feed-in from PV and other sources

- Load peaks due to e-mobility

Here, details are particularly important. Intelligent retrofitting with powerful, compact, and interoperable measuring technology is therefore essential.

Our solution: Modular measurement systems for transformer stations

From a technical perspective, this is a highly flexible retrofit system, consisting of:

The Volt 1000 voltage measuring device

- Four-phase voltage measurement: L1, L2, L3, N

- Modbus RTU slave interface

- Easy access to current measurements via touch panel and display

- Threshold monitoring of all current values, voltages, and phase shifts

- Measurement data from downstream Rogowski coils is transparently available

- Magnetic DIN rail mounting

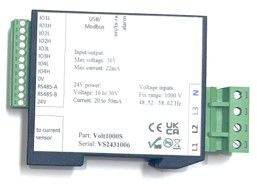

Volt 1000 S voltage measuring device

- Four-phase voltage measurement: L1, L2, L3, N

- Interface: Modbus RTU slave

- Threshold monitoring for current, voltage, and phase shift

- Measurement data from downstream Rogowski coils is transparently available

- USB connector with Modbus support for configuration

- Green power LED

- Red alarm LED

- Four configurable I/O pairs:

Alarm output, temperature, short-circuit/earth fault detector, door contact, current/voltage input - DIN rail mounting with clip

RoCo1065Ax / Cube 525Ax current measuring device

- Rogowski coils for easy and rapid installation

- Modbus RTU slave interface; up to 15 (or 20) devices can be cascaded using patch cables

- Current measurement is possible for 3 or 4 phases, with or without neutral conductor

- Coils are available with 65 mm and 110 mm diameters, and as a "Cube" with 25 mm

- Touch surface for measurement display on the Volt 1000

- Magnetic DIN rail mounting

- Threshold monitoring via connected Volt 1000

Benefits at a glance

| Feature | Developed in Europe |

|---|---|

Retrofit-compatible | No need to replace the station |

Compact design | Ideal for confined transformer stations |

Easy installation | Tools and configuration reduced |

real-time data | Control within the statutory deadlines |

Robust & durable | Suitable for industrial use and low maintenance |

Transparent measurements | Each disposal can be recorded separately |

Developed in Europe | Quality, support and delivery capability |

Practical solutions for implementing section 14a EnWG in grid operations

Typical application scenarios

- Retrofitting existing transformer stations within the scope of section 14a EnWG

- Network status monitoring for grid-supportive control (e.g. EV charging stations)

- Monitoring and alarming in case of voltage or load deviations

- Long-term data analysis for network optimisation and investment planning | In many cases, a closer look pays off – especially when existing infrastructure is to be preserved in a cost-effective manner.

Easy system integration

The measuring devices can be integrated directly into existing control systems via Modbus RTU. The combination of voltage metering, feeder current monitoring, and touch operation provides an end-to-end measurement and control platform – with minimal installation effort.

For this reason, it is essential to rely on a consistent system architecture that is compatible with both traditional and modern network control technologies.

Why Acal BFi?

As a European solution provider, we have been supporting municipal utilities and network operators for many years in meeting regulatory requirements.

Our modular measurement technology for implementing section 14a EnWG has been specifically designed for the challenges of the low-voltage level – robust, scalable, and ready for immediate use.

In the end, one thing counts above all: reliability.

FAQs on modular measurement systems for section 14a EnWG

§14a EnWG – often referred to as Paragraph 14a of the German Energy Industry Act or EnWG 14a – obliges network operators to control controllable consumption devices, such as heat pumps, EV charging stations or battery storage systems, in a grid-friendly manner. To do this in a legally compliant and efficient way, feeder-specific measurement in the low-voltage network is essential. Voltage, current and phase displacement must be measured precisely in real time, and the results must be available within a maximum of five minutes to detect, document and react to critical grid conditions. Without such measurement technology, compliance with §14a is practically impossible.

Many local substations in Germany were built decades ago – long before decentralised generation or high peak loads from electromobility became a factor. §14a EnWG, also referred to as the EnWG 14a measurement requirement, now demands precise measurement of current, voltage and phase angle. Retrofitting with modern modular measuring equipment allows these legal requirements to be met without replacing the entire substation – saving space, costs and time, while remaining fully compliant with the regulation.

Acal BFi supplies modular retrofit measurement systems designed specifically to meet the requirements of §14a EnWG. The system consists of voltage meters (Volt 1000 / Volt 1000 S) and current meters (RoCo, Cube). All units are modular, can be cascaded via patch cables, and communicate via Modbus RTU. They record all relevant parameters – voltage, current and phase displacement – in real time, monitor threshold values, and feed the data directly into the control room or SCADA system to ensure full compliance with §14a requirements.

Depending on the configuration, the systems can monitor up to 15 or 20 feeders individually. This EnWG 14a measurement is feeder-specific, allowing operators to perform detailed analysis rather than relying on aggregated values. The connection is made simply using standard patch cables – eliminating the need for extensive rewiring.

The devices feature standardised communication interfaces such as Modbus RTU, enabling seamless integration into existing control, SCADA or visualisation systems. Measurements are transmitted in real time to ensure that operators can act within the reaction times specified in §14a EnWG. An integrated touch display also allows local readout, ensuring operators always have access to the necessary information.

Installation is optimised for retrofitting and minimal disruption. The voltage meter is mounted on a DIN rail, while Rogowski coils are placed around conductors without the need for disconnection. This design makes it possible to meet the Paragraph 14a measurement requirement even in confined local substations – without lengthy outages or major modifications.

Yes. The Volt 1000 includes integrated threshold monitoring for current, voltage and phase displacement. If a threshold is exceeded, an immediate alert is triggered – either visually via LEDs or through digital I/O outputs to the control system. This enables operators to react immediately to critical network conditions, as required by §14a.

Absolutely. The systems are suitable for both new builds and retrofits. For new installations, the measurement technology can be integrated from the outset, ensuring compliance with §14a EnWG from day one. The modular design also allows easy expansion for future requirements.

Unlike standard energy meters, these systems provide feeder-specific real-time measurement, support grid condition monitoring under Paragraph 14a, and offer configurable threshold alarms. They not only meet the legal requirements but also enhance network transparency, support preventive maintenance, and improve long-term grid planning.

Directly from Acal BFi. Our specialists provide tailored advice, technical datasheets and proven solutions for implementing the §14a EnWG measurement requirement. We support municipal utilities and energy suppliers from the initial planning stage through to commissioning, ensuring compliance, efficiency and reliability.