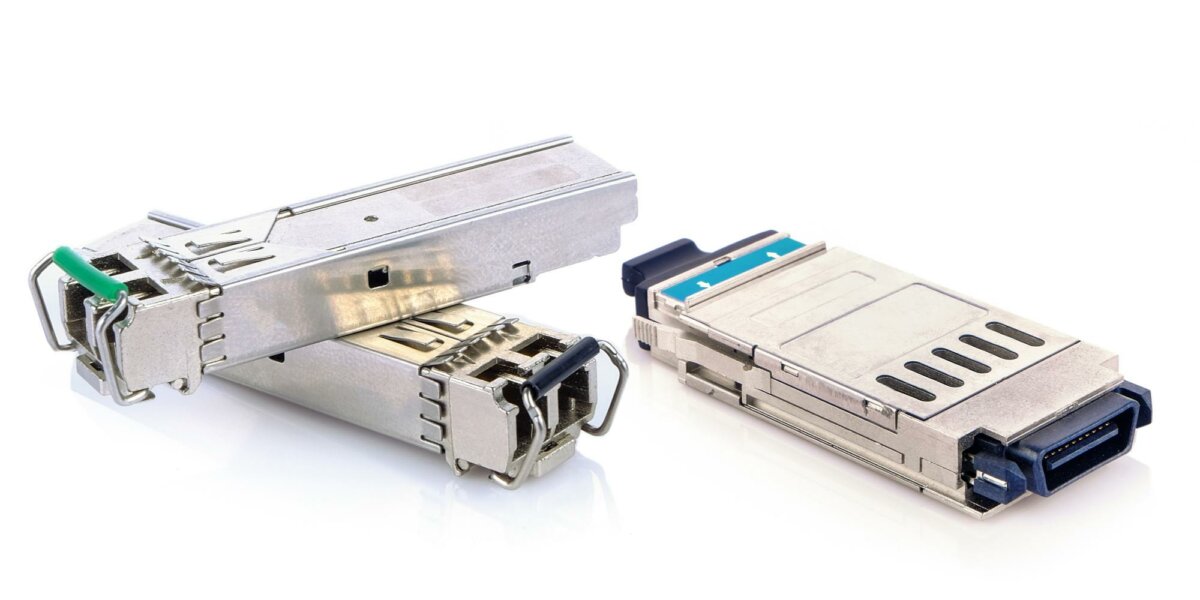

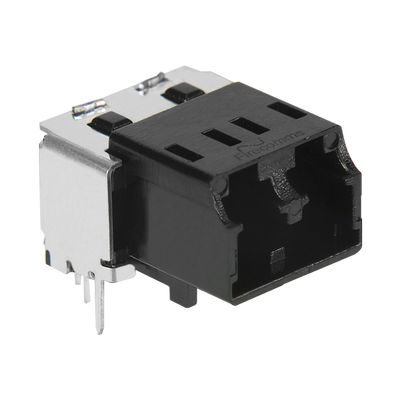

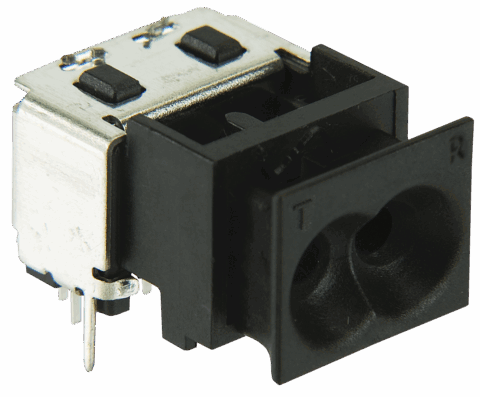

Fibre optic transceivers – 1×9, SFP, CSFP, XFP, QSFP & custom solutions

Find the right fibre optic transceiver for your application

Combining both a transmitter and receiver into a single housing, we cover a selection of transceivers that are suitable across many applications including industrial, harsh environments and high noise.

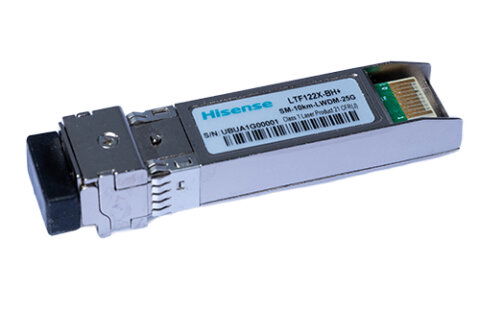

Our transceivers offer compact, reliable, durable and flexible options that are resilient to vibration, yet still allowing operation in an optimal wavelength range and directly modulated at high frequencies covering both digital and analogue options.

All products have been designed with a focus on achieving low-power consumption over a wide operating temperature range, and beyond and are available with conformal coating, additional shielding or special mechanical robustness demanded of rugged installations.

We have been long-standing partners with the leaders in fibre optic transceiver technologies and provide a wide range of high-quality products. Their strength in product customisation and flexibility of design enables also allows our fibre-optics experts to meet any bespoke requirements.

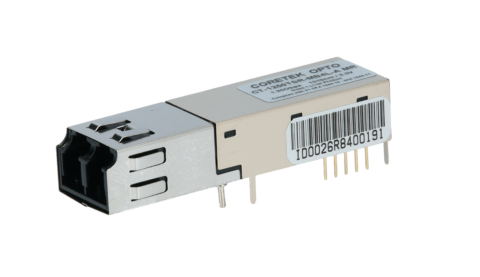

Covering a choice of either multiple supplier agreement (MSA) form factors, such as 1×9, SFF, SFP/CSFP, SFP+, XFP, QSFP+/QSFP28/QSFP-DD or customised footprints. Our technical consultants will also work with you to ensure optimum performance and usability through our test and support services and for custom solutions.