Multicore Optical Fibres

- Technology

- Speciality fibre

- Partner

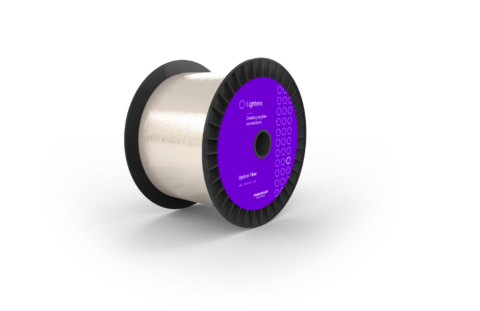

- Lightera (formerly OFS)

Lightera (formerly OFS) MCF are available with core numbers ranging from four to eight as both MM, SM, and a combination of both types of core inside one common cladding.

Applications for MCF include high-bandwidth, high density data transmission in Quantum Key Distribution (QKD), data centre Active Optical Cables (AOC), and several sensing applications for temperature, strain, next generation optical amplifiers (OA), and structural health monitoring (SHM).

Lightera (formerly OFS) shape sensor optical fibre uses twisted MCF with continuous FBG (Fibre Bragg Grating) for use in medical robotic surgery, catheter, biopsy needles and endoscopes, and for aerospace and defence, for example aircraft wing monitoring.

Range features

A high level overview of what this range offers

- Key benefits for shape sensor optical fibre include high fibre integrity and strength, stable signal quality, and good signal-to-noise ratio due to precise positioning of FBG.

- Customisable FBG to meet high-demanding and challenging 3D shape sensing specifications

- Typical fibre core geometry is three around one core or six around one core

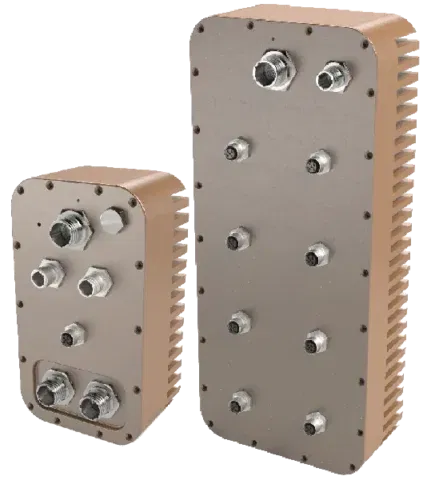

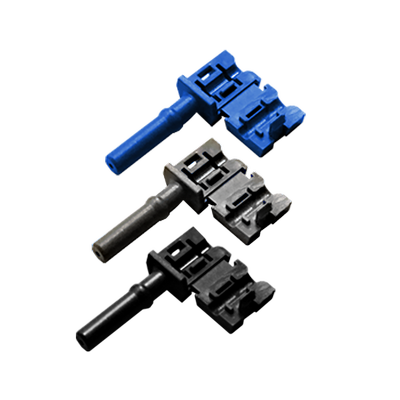

- Multicore fan-out with break-out box available

- Custom designs possible with fewer/more cores, core positioning/spacing and variation of core types (MM or SM)

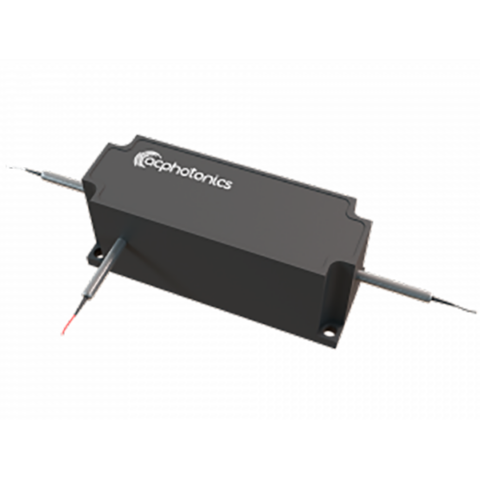

- MCF can be used for photonic integrated circuit (PIC) interconnects due to the significant space savings that can be achieved

- Custom MCF for distributed sensing in harsh environments with low loss performance, low crosstalk between cores in a small cross-section

Downloads

for Multicore Optical Fibres