The power of BLE in real-world applications

Bluetooth Low Energy (BLE) is a core technology in the current landscape of embedded systems, industrial automation, and IoT devices. Since its introduction in Bluetooth 4.0, BLE has been engineered with a singular focus – providing robust wireless connectivity while consuming minimal power.

That’s a game-changer for applications where devices need to run off tiny batteries for months or even years on end, such as industrial sensors, wearables in healthcare, or distributed environmental monitoring equipment.

This article examines BLE’s applications in industrial and embedded environments, highlighting technical use cases, the protocol’s unique advantages, and design considerations for selecting and deploying BLE hardware effectively.

Table of Contents

- Key BLE application areas

- Why BLE Fits embedded and industrial designs

- From features to function: How BLE enables applications

- Benefits of BLE-based applications

- Example use cases

- Selecting the right BLE hardware

- Strategic and business considerations of BLE applications

- How we support BLE applications

- Conclusion

BLE fundamentally differs from Bluetooth Classic due to its low-duty-cycle operation. Devices remain in a low-power sleep state most of the time, waking only briefly to transmit or receive data. This architecture is central to BLE’s impressive power efficiency and makes it suitable for deployments where battery replacement or maintenance access is limited.

With a highly configurable and layered protocol stack, GAP (Generic Access Profile), GATT (Generic Attribute Profile), and L2CAP (Logical Link Control and Adaptation Protocol) and features like Mesh networking, BLE enables reliable, structured data exchange for everything from predictive maintenance to asset tracking.

What are they key BLE application areas?

If you’re weighing range, power consumption, mesh requirements, or antenna design, our experts can help you navigate the options.

Accelerate your development with expert BLE advice – connect with our team now.

Why BLE fits embedded and industrial designs

Bluetooth Low Energy (BLE) fits right into embedded and industrial designs because it’s engineered to be lean and efficient. The protocol stack is modular and lightweight – so it doesn’t eat up microcontroller resources. You can fit the stack (GAP, GATT, L2CAP, HCI) in under 150KB of flash and 20KB of RAM. That means even entry-level MCUs like the Cortex-M0 or M3 can function without breaking a sweat.

Power efficiency? BLE’s practically built for it. Devices can sit in deep sleep, drawing less than 1μA. When data needs to move, they wake up briefly, transmit in short bursts, and use just 5–15mA when active. This event-driven setup means they’re only wake when something actually happens – sensor triggers, timed interrupts, whatever. That keeps the average power drain ridiculously low which means BLE is perfect for battery-powered stuff in tight or remote spots.

You also get dynamic role switching. So, if a sensor needs a firmware update or diagnostic check, it can step up from “peripheral” to “central” mode on the fly. This makes remote maintenance and upgrades painless – no need to physically interact with the devices.

Interoperability is another win. BLE works out of the box with all the major mobile platforms, embedded Linux systems like Raspberry Pi, and most commercial gateways. Devices can talk to apps or cloud services using GATT-based APIs. Secure OTA (over-the-air) updates? No problem. You can patch and upgrade after deployment without ever touching the hardware. Bluetooth 5.0 brought more flexibility with selectable PHYs. Engineers can pick 1M or 2M for higher throughput, or LE Coded for extended range – very useful in industrial settings with a lot of RF noise or tough physical barriers. All that, and it doesn’t increase power consumption.

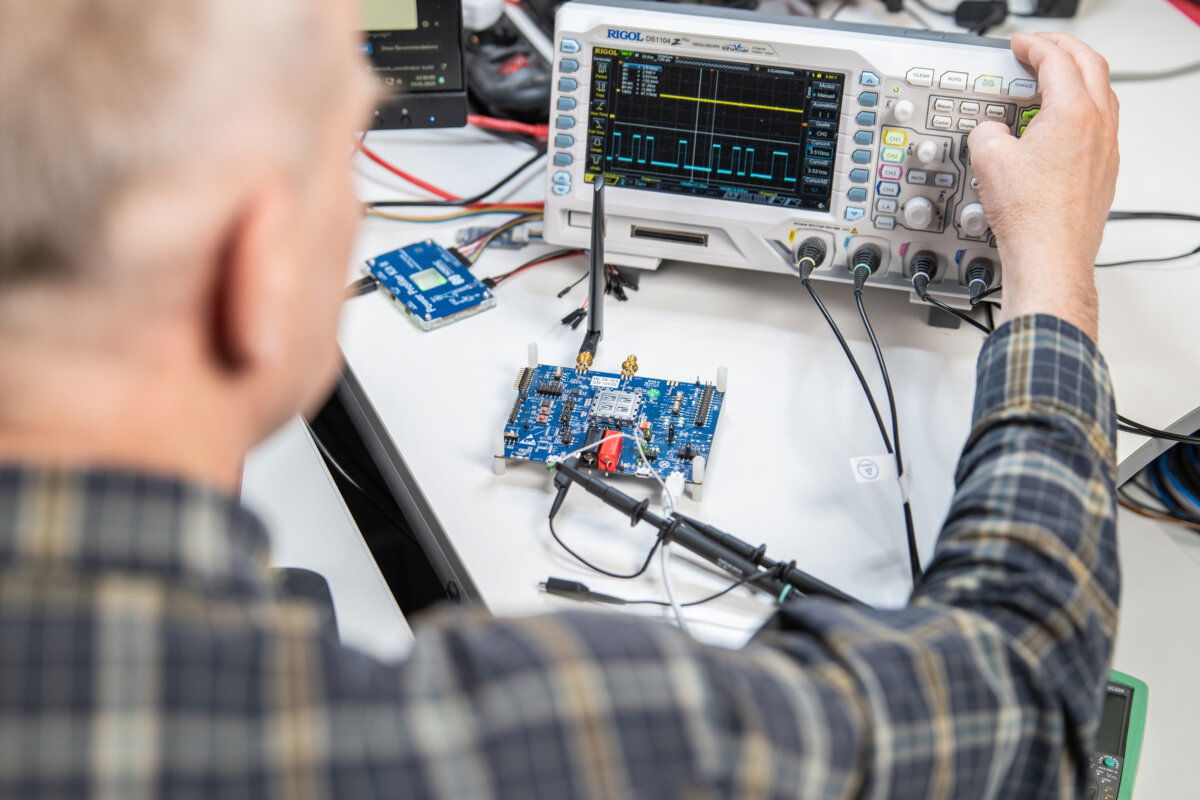

Antenna and RF design still matter, of course. Since BLE runs at 2.4 GHz, PCB layout, antenna placement, and enclosure choice all play a role in getting solid wireless performance. By using pre-certified SoCs and modules from companies like Reytac, you will simplify compliance (CE, FCC, Bluetooth SIG) and help speed up the development cycle. There are plenty of reference designs and eval kits out there to help get systems up and running fast, with reliable connections.

Bottom line: BLE’s technical architecture, power profile, role flexibility, and broad compatibility make it a strong fit for embedded and industrial applications where size, power, and reliability are non-negotiable.

From features to function: How BLE enables applications

Core architecture: GAP, GATT, and BLE stack flexibility

Bluetooth Low Energy’s efficiency is all about its protocol stack. You’ve got GAP (Generic Access Profile) and GATT (Generic Attribute Profile) doing the heavy lifting. GAP manages device roles, central, peripheral, broadcaster, or observer and keeps connections stable. It’s basically monitoring device communication, making sure everything starts and stays running smoothly.

GATT, meanwhile, is where actual data flow happens. It organises info into services and characteristics, which is important for keeping things streamlined. Devices like smart lights, industrial sensors, and wearables use GATT profiles to keep firmware simple and response times quick.

The real advantage? The whole BLE stack is modular and lightweight. That means it drops right in to different microcontrollers with minimal issues. Perfect for engineers chasing ultra-low power and tiny footprints in their designs.

PHY options and transmission flexibility

With the introduction of Bluetooth 5.0 and beyond, BLE added support for multiple physical layer (PHY) options, giving engineers more choice to optimise speed, range, or energy usage. The 1M and 2M PHYs handles data rates up to 2 Mbps, so you’ll get fast data transfers and cut down on radio airtime.

Meanwhile, the LE Coded PHY uses forward error correction (FEC) to push BLE’s range beyond 200 meters under the right conditions, and does it without having to draw more power.

This flexibility opens up a lot of deployment strategies. For example, a 2M PHY may be used for fast-speed updates when devices are close to one another, like factory equipment – while LE Coded PHY is better suited for relaying information across large facilities. Basically, BLE’s PHY options let engineers adapt to the physical layout and environmental demands without compromising power efficiency.

Periodic advertising and beacon broadcasting

Advertising sits at the core of BLE, driving communication between devices without the need for formal connections. Devices push out quick data packets – UUIDs, sensor data and status updates, into the ether, letting nearby receivers pick them up. That’s basically what makes BLE perfect for low-power, passive setups: asset tracking, environmental sensors, retail beacons, you name it.

With BLE 5.0, things got a major upgrade for periodic and extended advertising, which means engineers can fine-tune how often those packets go out (anywhere from 20 milliseconds to over 10 seconds) and how much data fits in each one. There’s more room to optimise and tweak transmission power, set timing etc, so devices stay responsive but don’t burn through batteries.

That’s the advantage behind BLE’s longevity in logistics, healthcare, and smart infrastructure. Devices will just keep running for years off a single coin cell, sending out blips and keeping the whole system going.

BLE Mesh networking: scalable and reliable

BLE Mesh is basically a decentralised network protocol that lets many devices talk to each other directly with no central controller required. It leverages BLE’s advertising bearer so devices can relay messages across the mesh, which makes the whole thing really robust; if one node has an issue, the network still holds up. That’s why you see this all over smart lighting, industrial sensor systems, and building automation setups.

The protocol uses a publish-subscribe model with managed flooding to move messages around efficiently. Devices in this environment can be relays, proxies, friends, or low-power nodes (LPNs). LPNs, for instance, mostly stay asleep and only wake up when their designated friend node needs to send them data.

This approach greatly reduces power consumption, so you can run sensors or access systems on battery for ages and because each device can take on different roles, you get flexibility and scalability that’s perfect for large networks where energy efficiency actually matters.

Secure and reliable communication

Security is critical in BLE deployments, especially in regulated sectors like healthcare, finance, and industrial automation. BLE addresses this with multiple layers of protection. LE Secure Connections, introduced in Bluetooth 4.2, uses Elliptic Curve Diffie-Hellman (ECDH) cryptography to establish shared secrets during device pairing, mitigating the risk of eavesdropping and man-in-the-middle (MITM) attacks.

For data encryption, BLE leverages AES-CCM, ensuring that transmitted information stays confidential and tamper-resistant. Device privacy gets an extra boost through address randomisation, making it much tougher for third parties to track devices over time. BLE also supports several pairing methods, Just Works, Passkey Entry, and Numeric Comparison, tailored to fit different hardware interfaces and varying security demands.

When it comes to device management, BLE enables secure over-the-air (OTA) firmware updates and provisioning, so there’s no need for direct access to devices once they’re deployed. That’s a serious advantage for embedded devices in remote, hazardous, or otherwise inconvenient locations, think smart city infrastructure or industrial sites where rolling a truck just isn’t practical.

BLE in battery-free and energy harvesting systems

BLE’s role in battery-free and energy-harvesting applications is quickly becoming a key area of development. Thanks to its ultra-low-power operation, BLE works especially well for devices that rely on ambient energy sources, things like photovoltaic cells, vibration-based generators, or even RF scavenging.

These SoCs boast standby currents down in the sub-microamp range and come equipped with on-chip energy-harvesting modules. The result? Devices such as BLE-enabled keyboards, asset tags, or environmental sensors that can run entirely off harvested energy, sometimes pulling enough from a single keystroke or minor movement to transmit brief data packets.

In logistics, this architecture means thousands of tagged assets can function for their entire service life without ever needing a battery change. In healthcare, it enables disposable BLE sensors for temporary patient monitoring, cutting down both costs and electronic waste. As Bluetooth Low Energy IoT devices expand into high-volume, cost-sensitive markets, energy-harvesting approaches are poised to become a cornerstone for sustainable and scalable product design.

Benefits of BLE-based applications

Bluetooth low energy technology brings a number of advantages when being implemented into designs. By combining its low power consumption, compact footprint and straight forward development, it enables engineers to design applications that are more efficient, reliable and compliant for modern industrial and embedded applications.

-

Extended battery life: BLE’s low duty cycle operation gives better power-saving features that enable devices to operate for months or years on a single battery. This makes it ideal for use in remote or maintenance free applications.

-

Compact design: The small footprint of BLE modules enables seamless integration into space-constrained devices such as sensors, wearables and portable equipment.

-

Fast integration: BLE’s modular stack and software development kits (SDKs) and reference designs significantly reduce complexity, development time and simplify system integration.

-

Certification ready: Pre-certified modules simplify regulatory compliance and accelerate the process with CE, FCC, and Bluetooth SIG standards, reducing testing requirements and overall costs.

Example use cases

The combination of BLE’s low power consumption, flexible data handling, and secure connectivity means that it’s well-suited for a wide range of applications. Here are a few key examples that illustrate its strengths in real-world designs:

Explore our portfolio of pre-certified BLE modules.

WPEQ-268AXI(BT) Wi-Fi 6E & Bluetooth 5.2 Half Mini PCIe Module

WPEQ-268AXI(BT) is Qualcomm’s first Wi-Fi 6E mini PCIe module supporting tri-band (2.4/5/6 GHz) with DBDC mode, allowing simultaneous dual-band operation and up to 160 MHz bandwidth.

WP7607 4G Cat-4 LGA module

The WP7607 module offers reliable device-to-cloud connectivity with an integrated application processor, Legato® framework, edge/cloud APIs, optional GNSS, and ultra-low power operation.

Selecting the Right BLE Hardware

When it comes to selecting the appropriate Bluetooth Low Energy (BLE) hardware, it’s a decision that could make or break your project. Engineers basically need to decide between integrating a discrete SoC or opting for a pre-certified module. Each option has its own set of trade-offs.

It’s not just cost and complexity you’re juggling, either. You’ll need to pay attention to the RF specs, stack compatibility, and how well everything ties in with your actual application needs. Power efficiency, performance, compliance, all at the same time. Overlooking any of these, could be trouble down further down the line.

BLE SoCs

A BLE SoC module integrates the radio, processor, and protocol stack onto a single chip. This setup is perfect for high-volume manufacturing where tight cost control and customisation are critical. Power consumption is impressively low, standby currents drop into the sub-microamp range, and typical TX/RX operation only draws about 4-10 mA. That said, the trade-off is a higher development burden: you’ll need to handle RF design, antenna tuning, and certification yourself. Still, if you need maximum flexibility and full control over both hardware and firmware, SoCs are the best option for deeply embedded systems.

Pre-Certified Modules

Pre-certified modules combine a BLE SoC with all the necessary RF components, crystal, matching network, antenna, or at least an antenna connector, into a single, ready-to-use package. Suppliers like Insight SIP offer these in compact form factors like castellated pads, M.2, and SMT, and they’ve already secured CE, FCC, and Bluetooth SIG certifications. That’s a huge win for developers: you can sidestep most of the RF headaches and regulatory testing, which seriously speeds up your development timeline. For teams chasing fast time-to-market or lacking deep RF expertise, this approach is especially practical.

Key hardware considerations

-

Antenna and RF performance: Antenna selection and placement are critical for reliable BLE communication. For applications requiring extended range, such as industrial automation or asset tracking, modules with external antennas or LE Coded PHY are recommended. Compact consumer products typically leverage chip antennas and 2M PHY for higher throughput and efficient short-range operation. Pay careful attention to PCB layout, enclosure materials, and antenna clearance. Follow vendor reference designs to minimise interference and optimise signal integrity.

-

Environmental conditions: Industrial-grade BLE modules are engineered to withstand extreme temperatures and high levels of electromagnetic interference. These are essential for deployments in harsh or unpredictable environments, ensuring consistent performance over time.

-

Power management: Achieving ultra-low power consumption is a priority for battery-powered or energy-harvesting designs. Key parameters include system idle current, sleep-to-wake latency, and the presence of integrated power management features. Advanced modules, support energy harvesting and offer sub-1 µA standby currents, enabling battery-free operation using ambient energy sources (light, RF, or motion).

-

Evaluation kits and reference designs: Fast prototyping and system verification are facilitated by comprehensive evaluation kits, which typically include USB debugging, sample firmware, and application-specific SDKs (e.g., for beaconing, sensor telemetry, or OTA updates). GATT profiles, connection scripts, and companion mobile apps are standard, streamlining development and validation. Reference software often includes middleware for RTOS integration, secure pairing, and serial communication protocols.

In summary, successful BLE hardware selection hinges on careful consideration of antenna design, environmental resilience, power management capabilities, and the availability of robust development tools and reference resources.

How Acal BFi supports BLE applications

Our team of experts provide end-to-end support for BLE implementation from concept through to post-production by providing:

-

Consultation: Expert advice on module selection, power budgeting, antenna design, and system integration tailored to the application.

-

Hardware supply: Access to pre-certified BLE modules, SoCs, and evaluation kits from leading manufacturers such as Reytac.

-

Design support: Assistance with stack integration, layout validation, power optimisation, and OTA architecture. Customisation options are also available for specific requirements.

-

Scaling: Guidance through prototyping, regulatory approvals (CE, FCC, SIG), and production ramp-up to ensure a smooth path to market.

Contact our BLE specialists to accelerate your design from concept to production with pre-certified modules, SoCs, and expert support.

Strategic and business considerations of BLE applications

Financial implications and power budgeting

BLE (Bluetooth Low Energy) is engineered for ultra-low power operation, with typical average current draws staying well below 20 µA. This means devices can function for years on a single coin cell. Battery swaps become practically obsolete, especially for anything deployed in hard-to-reach locations or remote sites.

In large-scale scenarios, think asset tracking networks or distributed environmental sensors – the operational efficiency BLE offers directly impacts total cost of ownership (TCO). Fewer battery replacements translate to major cuts in maintenance expenses and downtime. And with energy-harvesting BLE modules now available, it’s entirely possible to remove batteries from the equation altogether, further reducing both component costs and environmental footprint, which means serious gains in efficiency, sustainability, and budget control.

Administrative and integration benefits

BLE streamlines deployment by cutting out the need for heavy network infrastructure. Devices get provisioned and managed right from a smartphone or BLE gateway with no fuss, just direct setup and remote updates. Firmware pushes are all handled over-the-air, so there’s zero need for physical intervention after installation. Devices communicate directly, whether that’s through connectionless advertising, GATT connections, or BLE Mesh, no extra routers, hubs, or cabling required. That means reduced install costs and faster rollout, especially if you’re dealing with widespread or complex environments.

On the maintenance side, on-site configuration is handled via standard mobile apps or BLE gateways. Thanks to Device Firmware Update (DFU), updates happen wirelessly, eliminating downtime and manual labour. BLE’s native compatibility with iOS, Android, and embedded Linux makes it straightforward to integrate diagnostic and monitoring tools, supporting long-term reliability. Developers have more flexibility, standalone modules, SoC integration, or gateway-based solutions, depending on power and connectivity demands. BLE basically lets you fine-tune the implementation to match your technical requirements, no matter the scale.

Organisational impact Modular extensions, such as attaching a BLE beacon to industrial equipment, make adding functionality to older industrial equipment pretty straightforward – like plug-and-play upgrade. No need for a complete redesign or overhauling legacy systems; just add a pre-certified module and you’re up and running.

Pre-certified modules, reference designs, and development kits are widely available and since these already meet CE, FCC, and Bluetooth SIG standards, you can prototype quickly and sidestep the usual regulatory headaches. That lets your engineering team concentrate on building out application logic instead of drowning in compliance paperwork.

Most hardware suppliers offer robust SDKs packed with reference GATT profiles, beacon configuration tools, and integration samples. That means faster prototyping and smoother teamwork between hardware, firmware, and mobile groups. Standardised APIs and services keep integration efficient, so you get to market faster and with fewer surprises along the way. Time-to-market and development acceleration.

Certified BLE modules, those with CE, FCC, and SIG approvals, streamline the entire certification process. It’s a much faster route to compliance, cutting out a lot of the regulatory hassle that usually drags out development cycles. Acal BFi supports engineers with antenna design recommendations, practical reference layouts, and targeted integration advice. That’s a huge help for reducing design risks and optimising performance from the start.

BLE Products operate under the Bluetooth SIG’s established certification framework, so teams aren’t left reinventing the wheel. Leveraging pre-certified hardware shrinks both the cost and time needed to meet stringent radio requirements. With BLE’s standard 2.4 GHz operation, you get global compatibility without extra headaches.

The modules in this series come with minimal integration overhead and are essentially ready for certification right out of the box. For engineering teams working under tight deadlines and cost pressures, these modules offer a rapid, efficient path to market for connected solutions.

Conclusion

Bluetooth Low Energy (BLE) stands out as a specialised solution for low-power wireless connectivity, especially in embedded and IoT contexts. Its power consumption is impressively minimal, think sub-microamp sleep currents, making it ideal for devices running on coin-cell batteries or even battery-less setups.

The BLE protocol stack is purpose-built for efficiency. It’s modular and compact, so even microcontrollers with limited flash and RAM can handle it. Core layers like GAP, GATT, and L2CAP are optimised for structured, event-driven communication, which is crucial for reliable device interactions.

Recent protocol enhancements have pushed BLE’s capabilities further. Mesh networking supports many-to-many device communication. LE Coded PHY extends range for tougher environments, and LE Secure Connections delivers robust data protection, which is a must-have in serious industrial or healthcare applications.

BLE’s real-world use cases are pretty broad: predictive maintenance in factories, wearable diagnostic devices in healthcare, beacon-based access control, and asset tracking in logistics, just to name a few.

Choosing the right BLE hardware is critical. System-on-chips (SoCs) offer flexibility for custom designs, while pre-certified modules streamline regulatory compliance and speed up development time.

Providers like Acal BFi offer a complete ecosystem: certified hardware, technical support, and design consulting to smooth out BLE integration at every stage. If you’re engineering a compact, energy-efficient wireless solution, BLE delivers. It’s a mature, scalable platform with broad industry support and a clear path for future upgrades.