Die Herangehensweise an jedes Infrarot-Bildgebungsprojekt beginnt damit, dass wir genau zuhören, um sicherzustellen, dass wir Ihre spezifischen Anforderungen vollständig verstehen.

Acal BFi – Infrared Technology Centre

Wir entwickeln kundenspezifische ‘Infrarot-Lösungen’ für Ihre Anwendungen

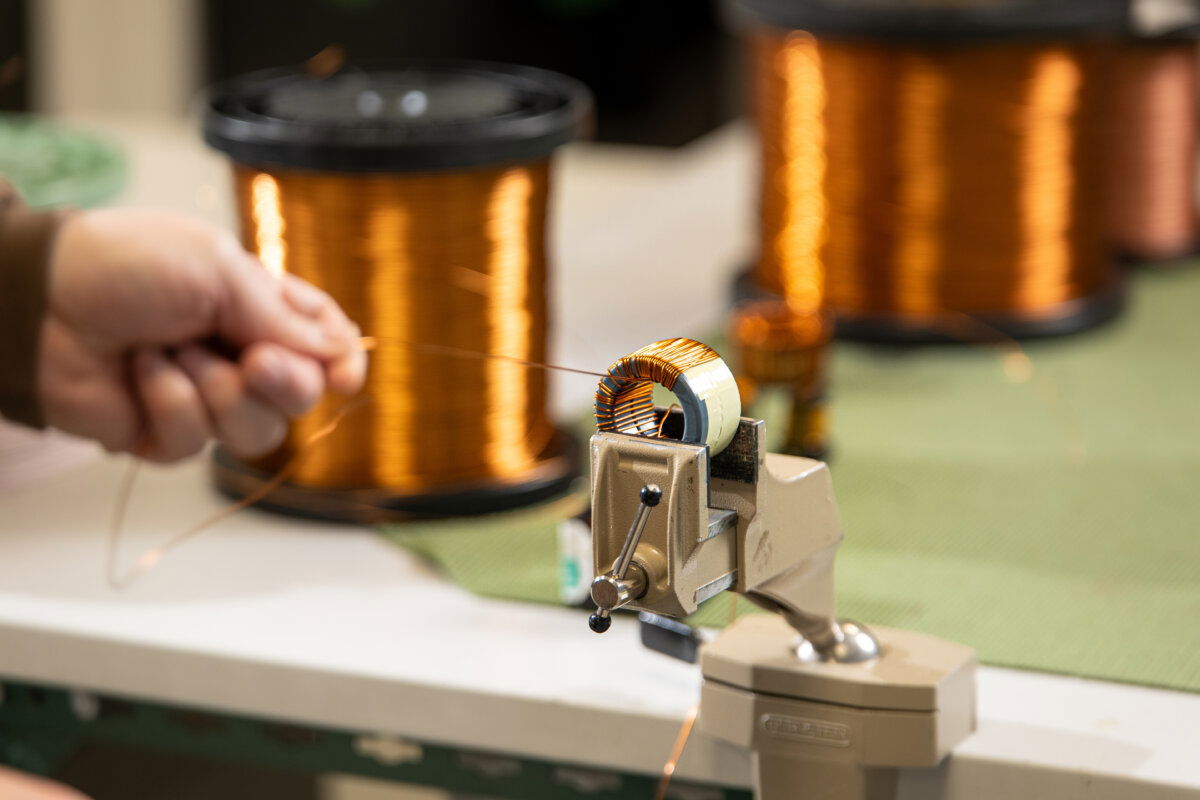

Während der letzten vier Jahrzehnte im Wärmebildbereich haben sich die Anwendungen für die Infrarot-Bildgebung stark verbreitert. Sie entwickeln sich aufgrund der Vorteile, die sie gegenüber der traditionellen sichtbaren Bildgebung bieten schnell weiter.

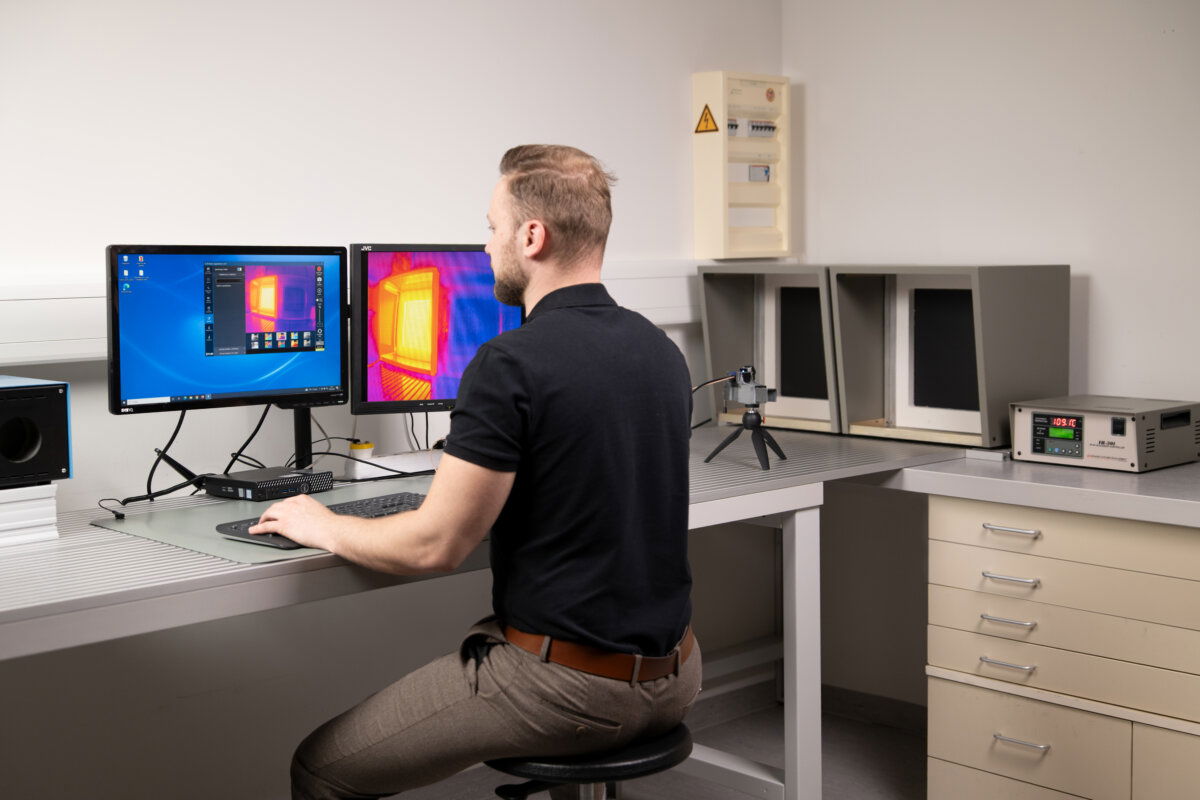

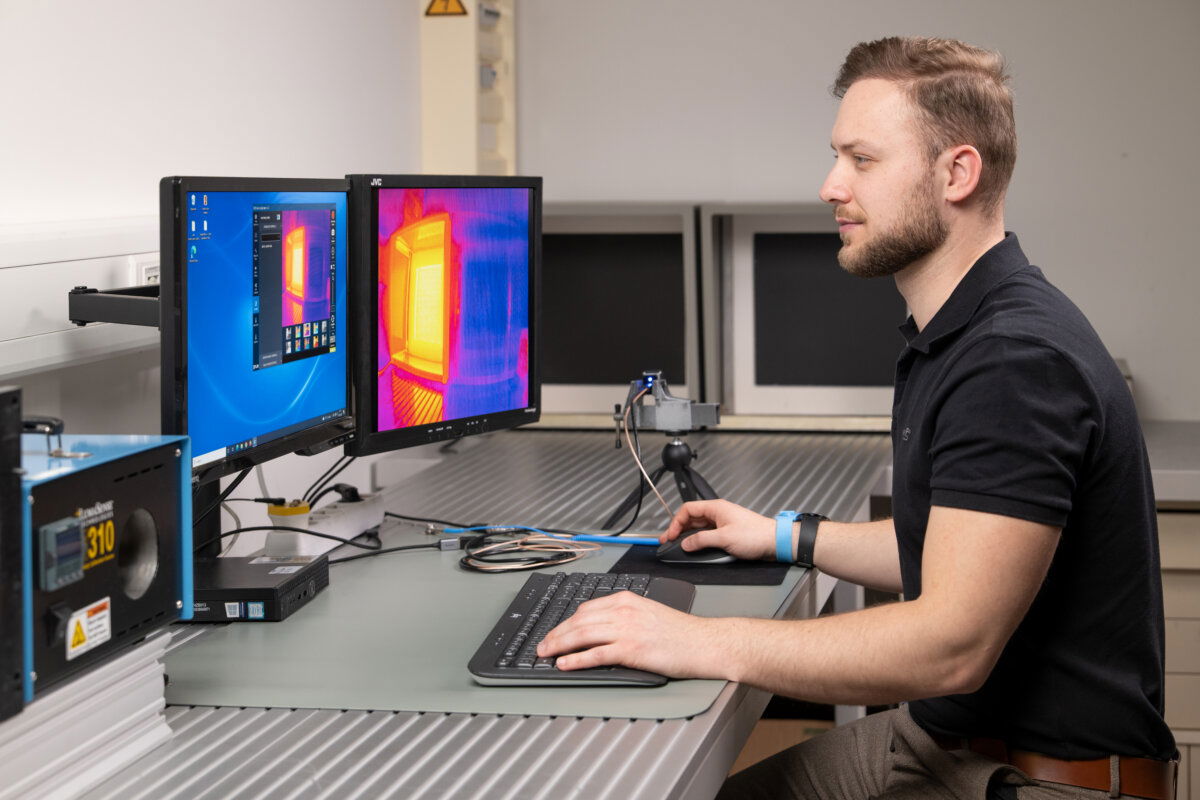

Mit einer Vielzahl von Anwendungen in diversen Märkten, von der Brandfrüherkennung in industriellen Anlagen bis hin zur Überprüfung erhöhter Körpertemperaturen im Reiseverkehr oder allgemeiner Zutrittskontrolle, ist es entscheidend, dass die richtige Kamera mit der korrekten Messmethode eingesetzt wird. Hier kommt unser Infrarot-Technologiezentrum ins Spiel.

Unser spezialisiertes Infrarot-Team steht Ihnen zur Verfügung, um Ihren Entwicklungsprozess von der Planung bis zum Fertigstellung zu unterstützen und sicherzustellen, dass Sie alles haben, was Sie brauchen.

Die Herangehensweise an jedes Infrarot-Bildgebungsprojekt beginnt damit, dass wir genau zuhören, um sicherzustellen, dass wir Ihre spezifischen Anforderungen vollständig verstehen.

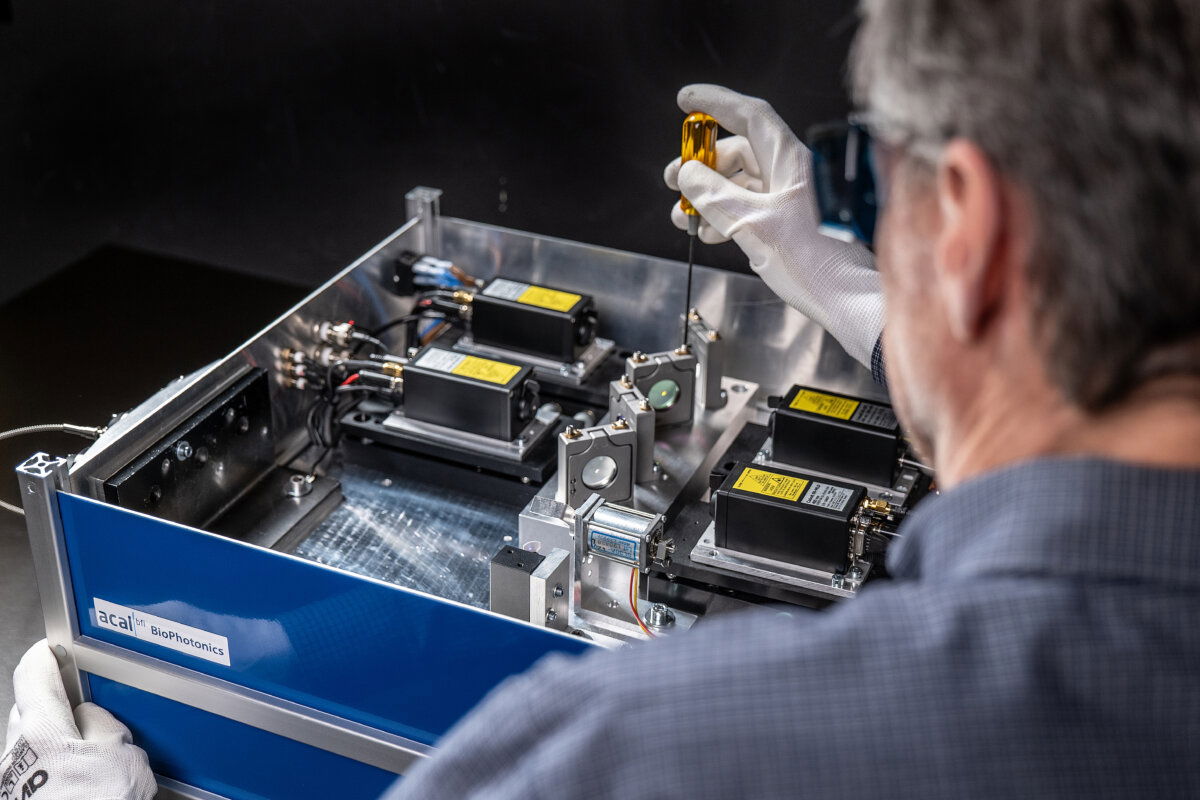

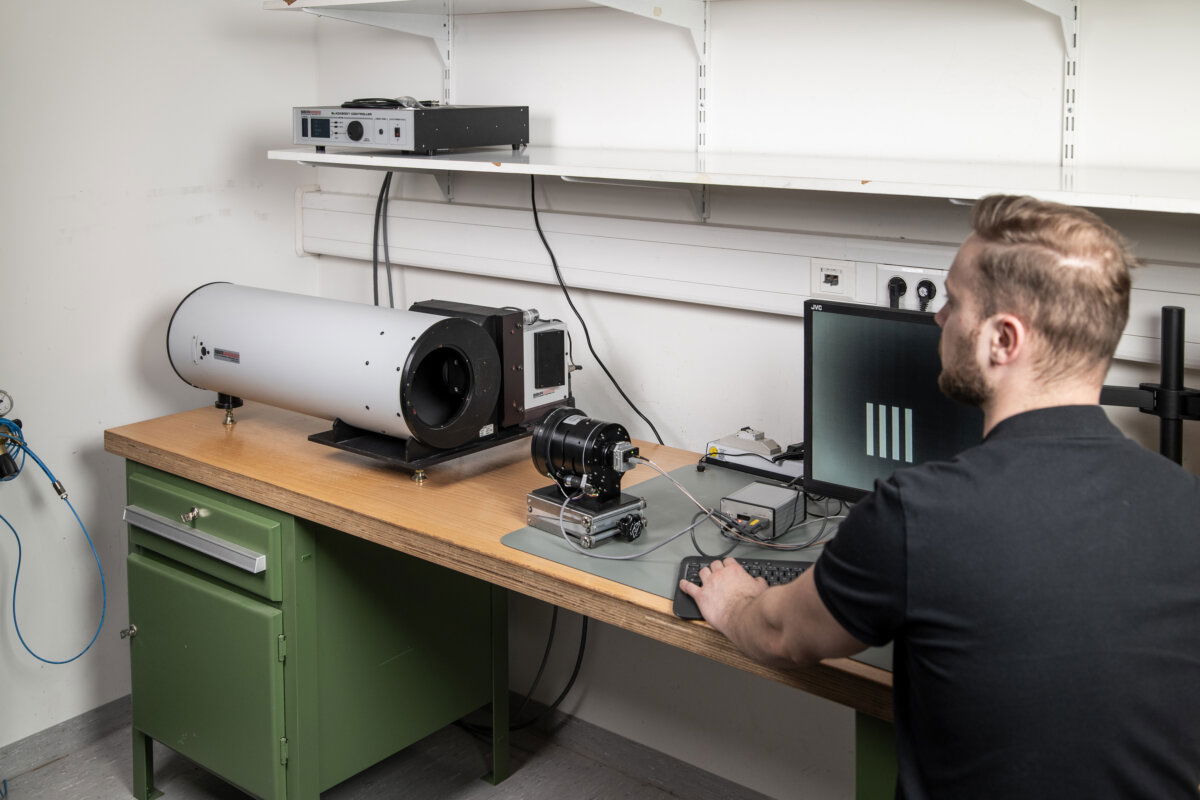

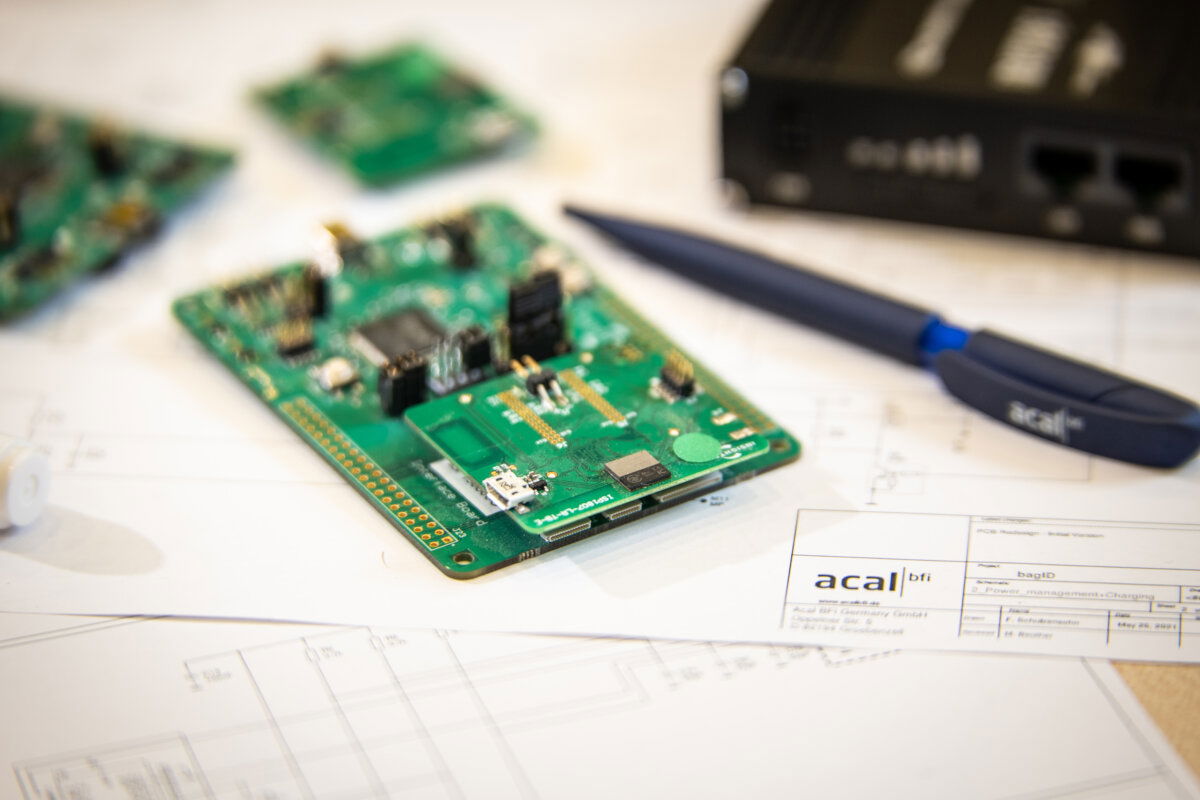

Erst dann können wir Sie über die am besten geeignete Infrarottechnologie und Messmethode beraten – von einfachen Detektoren über Kameramodule und Linsen bis hin zu Schwarzkörperstrahlern, Spezialgehäusen und Video-Prozessorboards – und Ihnen bei der Planung des Design-, Fertigungs- und Testprozesses helfen.

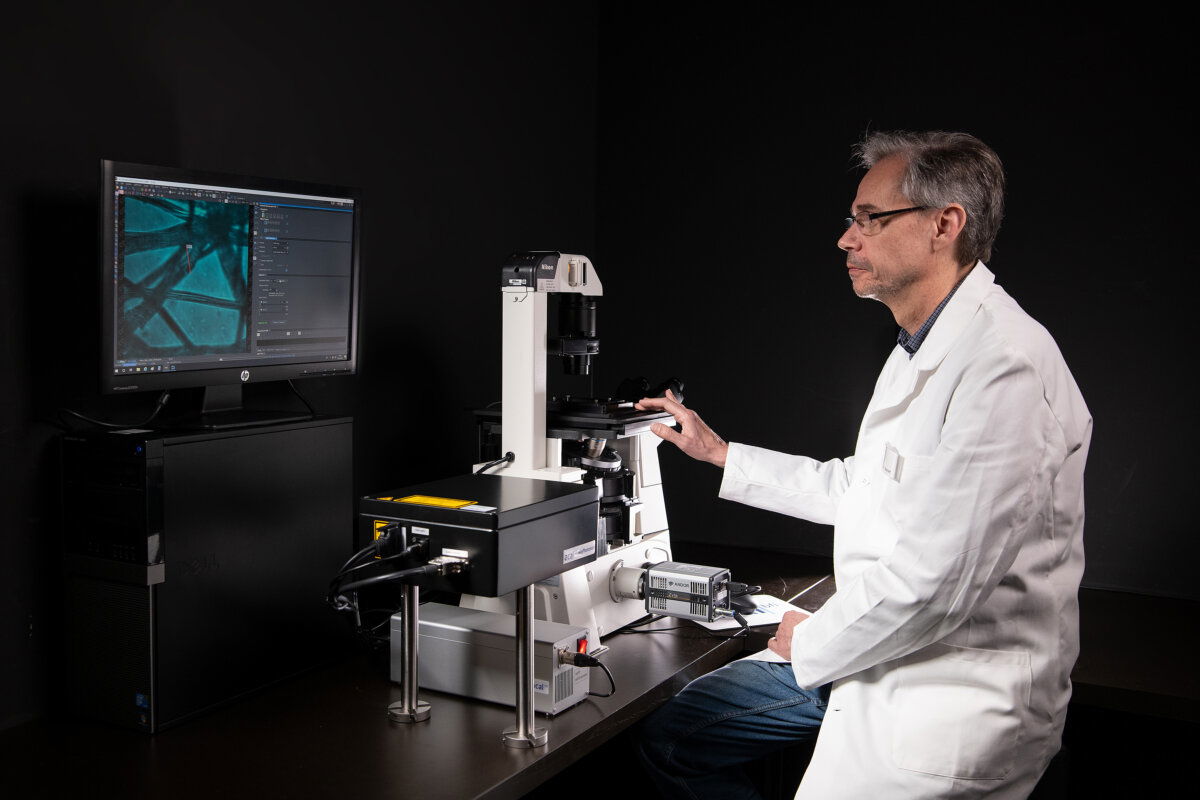

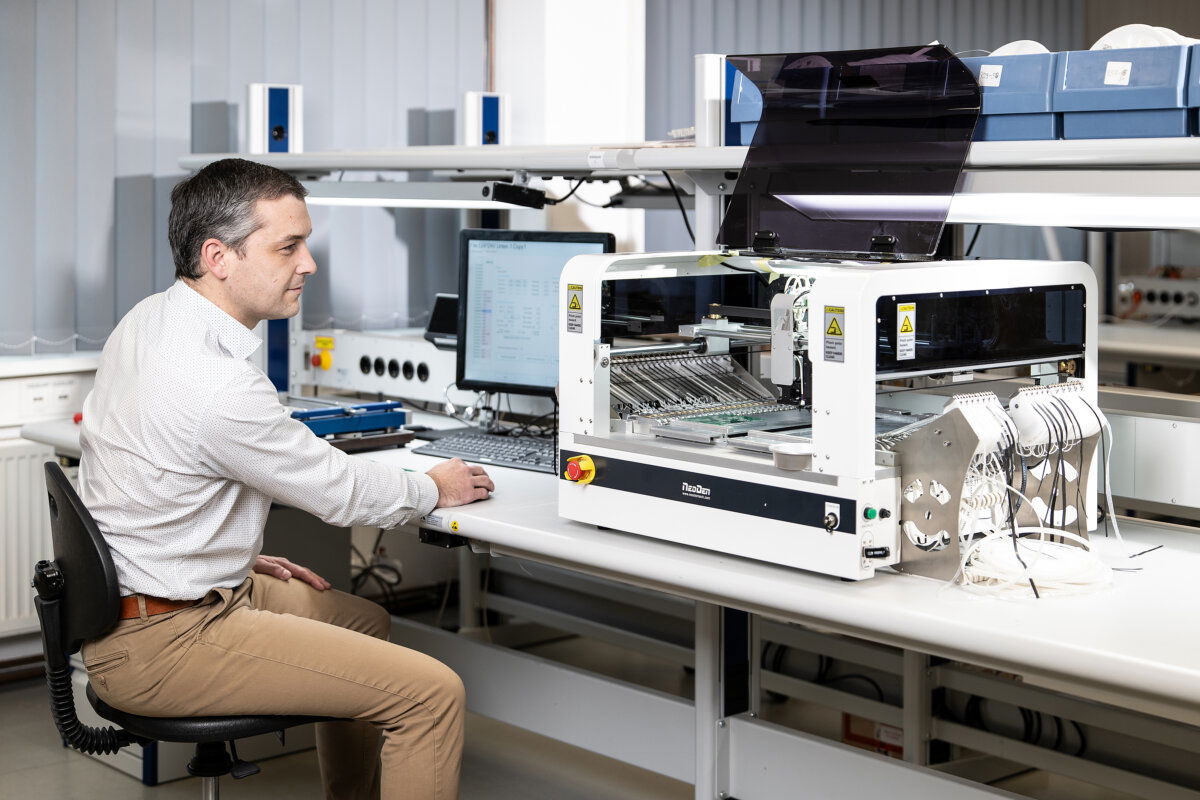

Das Infrarot-Technologiezentrum ermöglicht es uns, einen kompletten End-to-End-Support zu liefern und auch Leihgeräte und Vorführungen vor Ort anzubieten, um sicherzustellen, dass die von uns gegebenen Empfehlungen für Sie passend sind.

What we do at the Imaging Technology Centre?

The Imaging Technology Centre focuses on delivering high-quality, application-specific infrared solutions that balance performance, accuracy, reliability, and cost.

Every project begins by listening carefully to fully understand your technical, environmental, and operational requirements. Only then can we advise on the most suitable infrared technologies, from detectors and cores to lenses, blackbodies, processing boards, and complete camera systems and help you plan the design, manufacture, and test process.

In practice, we help you to:

- Define infrared imaging requirements based on real-world operating conditions

- Select the most appropriate infrared technology for your application

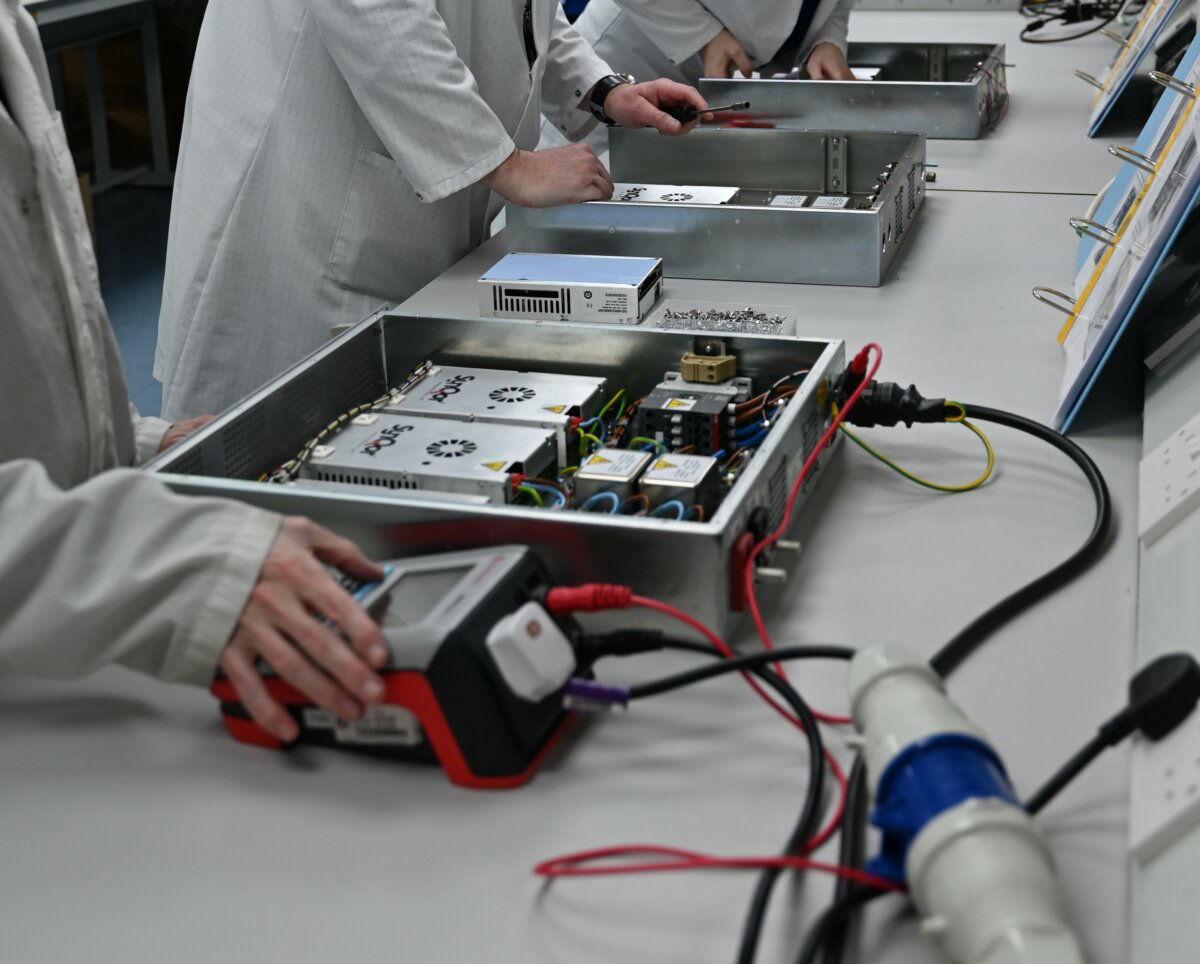

- Design and integrate custom or semi-custom infrared imaging systems

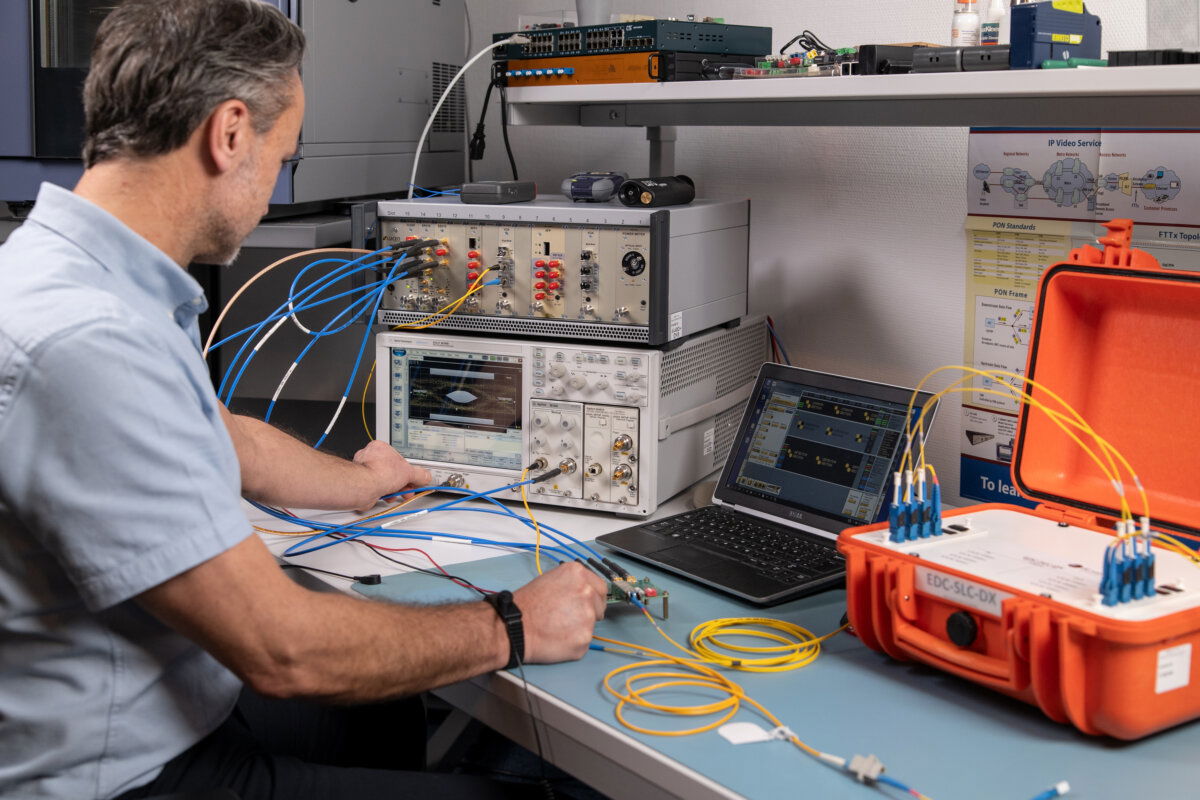

- Validate performance through specialist testing and calibration

- Reduce technical risk and accelerate time to deployment

Our role is to simplify complex infrared imaging challenges and help you deliver reliable, production-ready solutions with confidence.

Our expert team combines deep photonics and vision engineering knowledge with access to a broad portfolio of infrared cameras, sensors, optics, laser sources, illumination, and advanced imaging technologies. We help you select the right sensor architecture, optimise optical performance, overcome environmental and integration challenges, and navigate complex compliance requirements for industrial, medical, and defence applications.

Spezialisierte Infrarot-Funktionen

Innerhalb des Infrarot-Technologiezentrums können wir eine Reihe von Dienstleistungen anbieten, die Ihnen helfen, Ihre hochwertigen kundenspezifischen Lösungen zu realisieren.

Specialist Imaging Technology Centre capabilities

From configurable subsystems to fully bespoke imaging solutions – comprehensive support for your imaging requirements.

Navigating the complexities of imaging system design can be challenging. Whether you require a configurable camera module, a semi-custom optical adaptation, or a fully bespoke infrared or vision system engineered to your precise performance criteria, the Imaging Technology Centre provides a complete spectrum of specialist support.

From sensor selection and optical optimisation to processing architecture, calibration, testing, and environmental integration, we work alongside your engineering team to deliver imaging solutions that meet demanding technical, operational, and regulatory requirements.

Collaborative expertise across Acal BFi Technology Centres

The Imaging Technology Centre works closely with our other Technology Centres to deliver fully integrated system solutions. When additional specialist support is required, we can engage teams from the other Technology Centres to provide a complete, cross-technology offer. By leveraging a portfolio of advanced imaging, sensor, optics, wireless, and power technologies, we are able to deliver solutions that address the evolving challenges of modern industrial, defence, medical, and research applications.

Why work with the Imaging Technology Centre?

The Infrared Imaging Technology Centre is designed to support engineers and technical decision-makers at every stage of infrared system development, offering:

- Specialist infrared expertise backed by decades of experience

- Engineering-led support from concept through deployment

- Reduced technical and certification risk

- Access to specialist testing, calibration, and demonstration facilities

- A collaborative partner, not just a component supplier

Why Acal BFi? Your partner for imaging solutions

With decades of experience supporting advanced sensing and imaging technologies, Acal BFi combines deep technical expertise with access to a broad supplier ecosystem to deliver application-matched infrared solutions.

We provide:

- Hands-on engineering consultation

- Technology and component selection

- Custom and semi-custom infrared system design

- Testing, calibration, and compliance support

- Long-term lifecycle and supply chain management

Supported by centralised logistics and a pan-European engineering network, we help ensure reliable supply, technical continuity, and confidence throughout your product’s lifecycle.

Selection depends on factors including temperature range, sensitivity, resolution, environmental conditions, and regulatory requirements. Our specialists help define these parameters and recommend the most suitable technology.

Custom solutions are typically required when standard cameras cannot meet performance, form factor, environmental, or integration requirements, or when system-level optimisation is critical.

Yes. We offer specialist testing, equipment loans, and field demonstrations to validate performance in real-world conditions before final design or production decisions are made.

By supporting technology selection, system design, testing, and compliance early in the development process, we help minimise redesigns, certification delays, and performance issues later in the project.