Specialists in EMC shielding and thermally conductive products

In addition to the extensive range of standard components, MTC provides individual services and support – including consulting in projects as well as the development and production of individual solutions.

MTC is a sister company to Acal BFi, enabling us to consult and supply customers of different industries such as automotive, avionics, medical, telecommunications, and renewable energy around the globe.

Jump to:

Need to speak with an expert?

EMC shielding

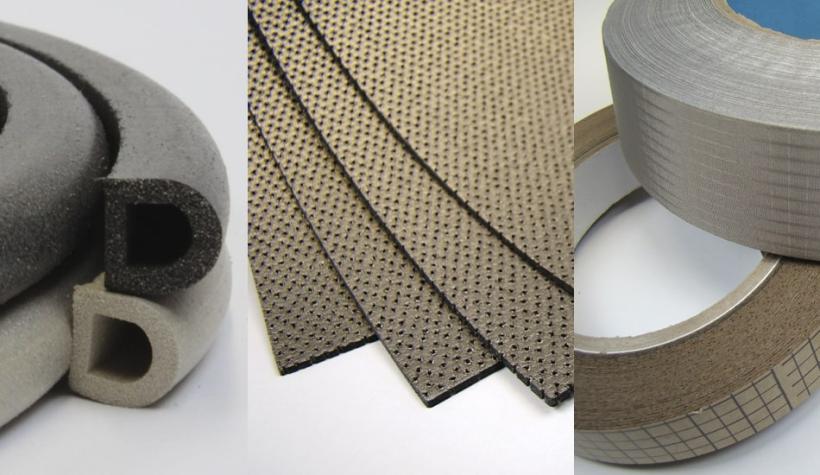

MTC produces a broad range of components and materials for the shielding of electromagnetic radiation, such as fabric-over-foam gaskets, electrically conductive foams, elastomers, tapes, and contact springs.

Available with either aluminium foil cover or conductive fabric with copper-nickel coating, these polyurethane foam cores come in three hardness grades and are fitted with a choice of conductive or non-conductive adhesives.

Electrically conductive materials of all shapes and sizes are used to shield and seal a multitude of applications. Various metals and materials are available in different dimensions, thickness, hardness, etc.

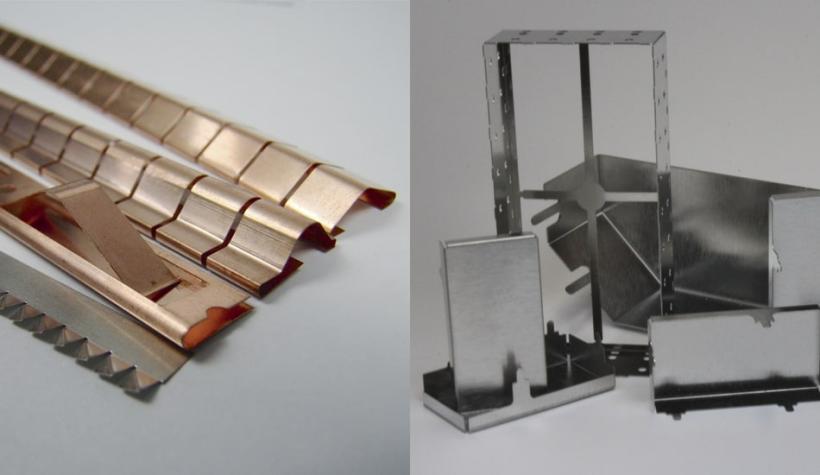

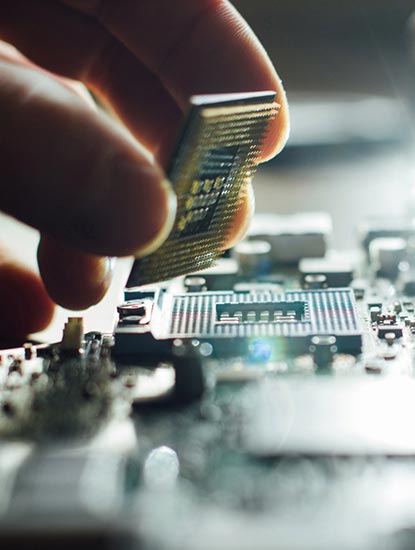

MTC’s contact strips are mainly used for chassis shielding. Board-level shields, SMD contacts, and shielding clips are used for shielding on the PCB.

Enabling easy shielding of cutouts in enclosures for display systems. Available as transparent fully laminated mesh windows, die-casted plastic windows, and glass/plastic windows with an electrically conductive coating.

Ventilation panels are for use in electronic enclosures that require good airflow and EMC compliance. Applications include electronic enclosures, air conditioning units, fan housings, EMC racks, and communication shelters.

Used to lower the "Q" of a cavity and absorb surface currents which degrade component performance. Fillers are "lossy" at microwave frequencies and absorb the microwave energy into heat.

Thermal conduction

MTC has a portfolio of products to optimise heat transfer between components and the cooling mechanism. These include thermally conductive paste, gap filler, conductive tapes, conductive insulators, dual sheet thermals, and absorbers.

Gap fillers are ideally suited for the bridging of small to large distances between the components and the heat sink. They are available as sheet material or stamped parts.

MTC's phase change material is based on wax and starts to melt and flow at temperatures between 45°C and 55°C. It is available in different material thicknesses and delivery forms.

Conductive paste is characterised by its excellent thermal properties. The product range includes paste with a thermal conductivity from 1.0 to 6.0 W/m*K.

Within the Magnetics Products Technology Centre, we offer an array of services to help create customised solutions.

With the largest team of technical support specialists in Europe, we are at the forefront of a design led approach to delivering challenging and custom solutions for magnetic cores or components for production.

Whether your need is simple or complex, we can develop a solution to achieve your goals. With in- house experts we can design, develop and test prototypes that meet performance and environmental requirements of your application.

Technical news and insights

Access industry news and Acal BFi articles, white papers and brochures

Enquire

Submit your enquiry directly to one of our Technical Sales Specialists.

Alternatively call our Sales Team.

Mandatory fields*

Our approach

When it comes to developing custom solutions for tomorrow's technologies, we trust our approach to deliver the best possible outcome.

Our engineers will skilfully guide you through each stage of your project, working with you to understand and identify a solution that meets your technical and commercial needs before designing and integrating your solution.

United Kingdom

United Kingdom