Optimise efficiency in Industrial IoT

With Industry 4.0 / Industrial IoT (IIoT) gaining more momentum within manufacturing, a company’s primary goal is to optimise efficiency. Requirement for more machines and devices across industries like manufacturing or agriculture are demanding continuous improvements and optimisation of technology and processes currently in use.

With rugged, industrial-grade sensors and wireless connectivity being embedded or located across factories, warehouses, vehicles, machinery and equipment, businesses can readily collect reliable real-time data and use it to transform processes and efficiency. Being able to better detect inefficiencies, avoid bottlenecks, excessive resource consumption or avoiding catastrophic failures from constant monitoring and maintenance of machinery, bringing more informed and autonomous decisions and cost-saving to the business.

How can we help you design for IIoT?

Thriving in the IIoT market requires speed and expanded expertise. As an end-to-end solutions partner, we can complement your knowledge and enable you to create solutions that will be able to solve specific challenges within industrial applications such as:

How can we help?

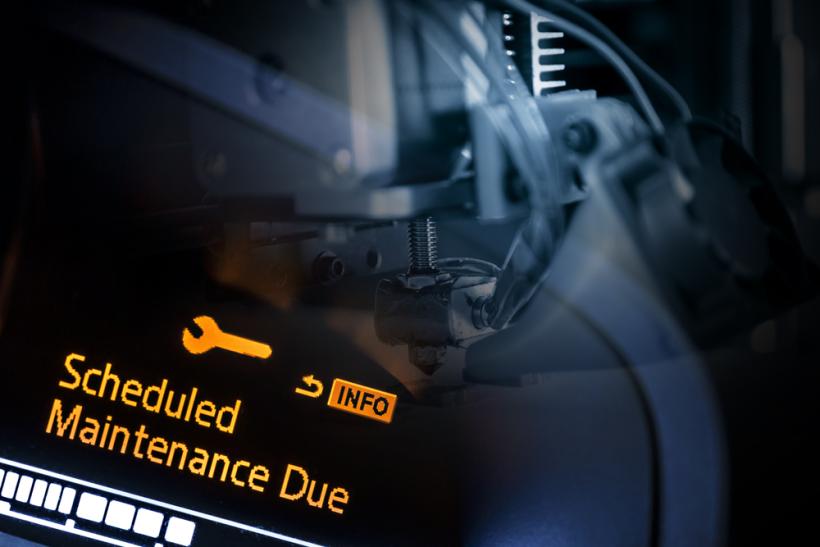

By monitoring machines and the environment around them using industrial Wi-Fi modules such as SparkLANs and smart sensors such as Cubic’s combined gas & particle sensors, production efficiency can be massively improved by reducing downtime, overall repair time and identify potential failures. Being able to schedule repairs and services during optimum times and identify when something is not running efficiently or failing means being able to alert employees of hazardous situations, avoiding emergencies and mitigating costly damages to machines or property. Devices monitoring the equipment functions can pinpoint the part or component in question eliminating “trial and error” searching for failed parts. This all leads to improved predictive maintenance strategies, better asset utilisation and enhanced uptime.

Attaching Honeywell Humidicon sensor devices to vehicle fleets enables monitoring of temperature/humidity conditions of raw materials and their cargo volume, downtime, and installing GPS such as an Airoha AG3335 SOC module (which is up to 10 times more efficient than its competition) accurately monitor their delivery times and exact locations. With more information about routes, downtime, number of orders etc. business can check their performance and perform any maintenance or make decisions about vehicles in operation at any given moment. Having cloud/ IoT management software such as Sierra Wireless AirVantage to receive this real-time tracking information as the product moves through the supply chain will give greater visibility that can help calculate and avoid potential problems early, reducing costs further down the line.

Effective data analysis through the monitoring of accidents, injuries, health-related absences, equipment/property damage, decisions can be made on how the personnel in the plant should be organised, how many breaks they should take, rectify any potential equipment issues before an accident or breakdown occurs, monitor and rectify the environment in which they work to prevent sickness and develop a better safety plan.

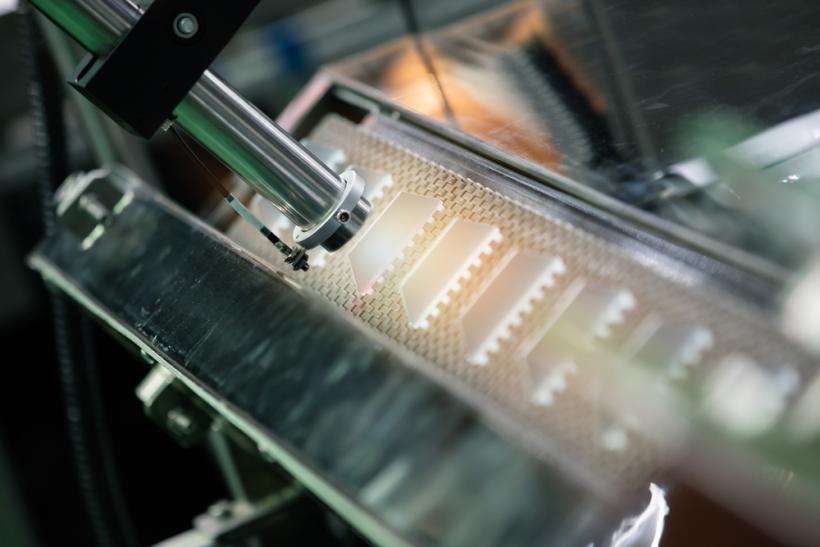

Equipment with embedded or retrofitted devices gives operators and managers complete visibility over the production floor. Tasks do not need to be visually verified to know if they are complete, and if the system shows a drop-in performance, resources can be deployed automatically to bring them back up to speed. Having data and information about the manufacturing process such as; how long it takes machines to start, how long they are in operation, how often interruptions may occur or highlighting any problems in the machinery, streamlines the management of production by eliminating material wastage and time on production. The whole process becomes more energy-efficient and saves operational costs due to predictive maintenance and corrective measures.

Collecting data on the internal locations of products and the distance travelled by operators allows companies to reach an intelligent warehouse design, that can also gather data with Honeywell sensors on temperature, humidity, or exposure, as well as energy consumption in the warehouse to ensure efficient management of resources and prevention from damages to products.

With information that allows the better planning of orders and make accurate predictions based on stock levels, managers can then determine how much is used and when inventory should be ordered and then in turn schedule future production requirements.

Software controlled automation and data collection from a huge sensor network connected to a highly secure Lantronix gateway and cloud server platform provides continuous monitoring and analysis of each stage to ensure optimum quality and damage control. Through the various stages which products go, IoT sensors collect the cumulative data starting at which kinds of raw materials are used, parameters like temperature, wastage, and can then be used to identify quality issues.

The use of IIoT and Sierra Wireless’ AirVantage cloud software to give advanced data analytics could have a huge impact. It is about doing jobs that already exist more efficiently or enabling people and machinery to carry out tasks that previously were not able to be done which not only improves production, but companies will gain a competitive edge over those who don’t use IIoT technology.

Custom Services

With access to the R&D teams behind the world’s most advanced sensing technologies, we can design, develop and build custom sensor assemblies quickly and easily. By combining our own in-house knowledge and experience with the skill and resources of our supplier partners, we can help you to develop groundbreaking designs which incorporate the most advanced sensing technologies.

Contact us about utilising our sensor and connectivity expertise to design a complete solution that meets your projects design requirements.

How can we help?

Our IoT and Wireless Technology Centre will advance your ability to deliver innovative technology solutions for complex applications – from sensors to the cloud.

Creating custom solutions and navigating adding challenging connectivity to an application requires specialist expertise and capabilities. Our team of hardware design and software application engineers have extensive experience, ensuring we can bring your concept to life.

Covering proof of concept and feasibility studies for development, through to working prototype realisation and initial production management, our team delivers you complete project support.

Sweden

Sweden