Custom fibre optic cable assemblies for demanding applications

The best solution for your application

With a purpose-built fibre assembly facility, an intimate knowledge of fibre coatings, and access to a wide range of specialist optical fibre cables and connectors for all applications, we can work with you to select the right fibre for your system - whether operating in single-mode or multi-mode. We also define the correct cable and connection system to meet the specific environmental operating conditions of your system, then manufacture a bespoke solution at our purpose-built facility.

Your fibre optic partner

Working with Acal BFi brings many benefits to your project. From our UK based custom service centre, our experienced technicians can assist with your project from concept to final production, ensuring it is delivered to specification, on time, and on budget. We also offer a range of logistics services designed to aid production efficiency and save you time and money such as stocking of manufactured goods, packing, labelling and delivery services.

The benefits of our unique custom fibre manufacturing service include:

- Improved system performance - optical fibre cable assembly is optimised both mechanically and optically to your system needs.

- Wide range of fibre types - to suit data and telecom, industrial, high bandwidth, medical, aerospace, defence, transport and applications in harsh environments.

- Wide range of connector systems available - from crimp-and-cleave, through industry-standard connection systems such as Amphenol, to fibre metalisation and ferrules.

- Shorter development cycles - first article samples are generally available within 4-6 weeks.

- Total cost of ownership reduced - cable is supplied complete, tested and ready to install.

- State-of-the-art logistics - including just-in-time, Kanban, ship-to-line, and buffer-stocking to agreed levels support your inventory and cash flow.

- Delivery anywhere in the world - supporting delivery of cable assemblies directly to the required point of use.

- Reliability - all designs are manufactured to exacting standards in our own or our partners production facilities under ISO9001 quality control up to military standards.

Ruggedised fibre assemblies for harsh environments

We specialise in fibre and connector cable assemblies for harsh environments, and can incorporate a range of technologies such as multi-mode, single-mode, expanded beam technology and physical contact/butt joint technology to produce anything from a standard ruggedised cable to a hybrid, ruggedised solution incorporating fibre, copper and coax which is able to carry data, signal and power in one cable.

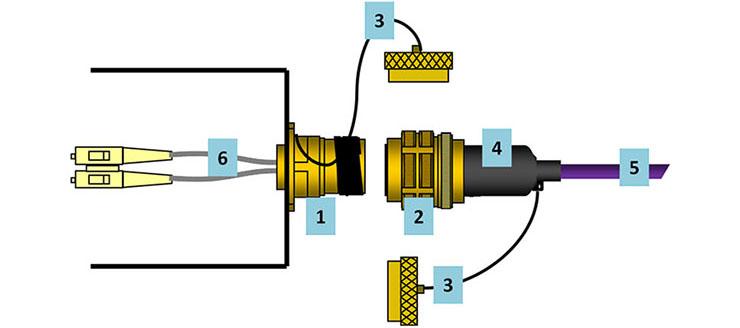

Typical ruggedised/harsh environment assembly list:

- 1. Receptacle - box/panel mount complete with fibre termini

- 4. Backshell and adhesive lined heat shrink boot shape

- 2. Plug shell complete with fibre termini

- 5. Tactical cable (Mil/SWA/industrial) and conduit as required

- 3. Protection cap complete with lanyard

- 6. ZIP cord to commercial connector (LC, SC, ST, FC/PC, SMA, MTRJ)

Plating materials:

- Nickel Aluminium Bronze - high salt spray resistance

- Black Zinc Anodised

- Black Zinc Nickel

- Stainless Steel

- ARCAP for corrosion resistance

- Electroless Nickel

- Olive Drab Cadmium

- Olive Drab Zinc Cobalt

Whatever the application, we have a solution

Our team of dedicated fibre specialist has considerable experience across a wide range of industry sectors, and we are able to solve your design challenges in any application. Whatever your industry or application, we can provide a custom fibre optic cable and connector assembly to meet your needs. We have provided solutions for applications in:

- Military and aerospace

- Security and CATV

- Commercial

- Industrial

- Communications

- Outside broadcast

- Mining

- Datacentres

- Telecommunications

- Transport (including road and rail)

- Marine and offshore systems

- Geographical survey

- Medical

- Oil, gas and energy

- Sensing

Strategic partners at the forefront of fibre optic technology

We have long-established relationships with the world’s leading fibre technology specialists and are a stocking assembly distributor for Amphenol connectors with a 50-year history. Other specialist suppliers include companies such as OFS who design and manufacture fibre optic cable, connectivity, FTTX and speciality optical fibre solutions for harsh and challenging environments.

Our experience and supplier contacts mean we can offer you a wide choice of fibre cables, including:

- ST,LC, LC Duplex, SC, SC Duplex

- SMA and MTRJ connectors, adaptors, pigtails, patch leads

- OFS GiHCS® industrial fibre cable

- HCS® optical fibre and cable

- Erbium-doped fibre

- Polarisation-maintaining fibre

- PYROCOAT® polyimide fibre

- Carbon-coated fibre

- HCXtreme™ fibre

- Geosil™ fibre

From our Fibre Optic Technology Centre we offer test and repair with a same-day assessment and 24-hour repair service. Our experienced technicians will quickly identify the problem and carry out repairs, then test the fibre to ensure cable and connector integrity and compliance.

Our facility is equipped with the latest technology including laser inspection and OTDR fault-finding, and we have polishing equipment with imaging for detailed inspection before final testing.

We offer both in-house and on-site test and repair services depending on the circumstances and have carried out repairs as far away as China and on a remote oil rig in Norway.

Working with Acal BFi gives you complete peace of mind, along with access to leading technology and manufacture, putting your project in safe hands.

If you have a project that requires a custom fibre solution, contact our sales team today for a no-obligation consultation.

The Fibre Optics Technology Centre is the driving force behind our ability to develop solutions requiring custom fibre capabilities.

When standard components don’t suit your requirements, we will support the design and development of custom software or hardware to fit your unique needs. The facility is also experienced in running diagnostic testing, fault finding and modification of components.

So, whether you need to analyse the performance of your optical components or understand your current power levels, our highly trained team of engineers are on hand.

Sweden

Sweden