Levering van hoogwaardige ijzerpoederkernen voor de elektronica-industrie

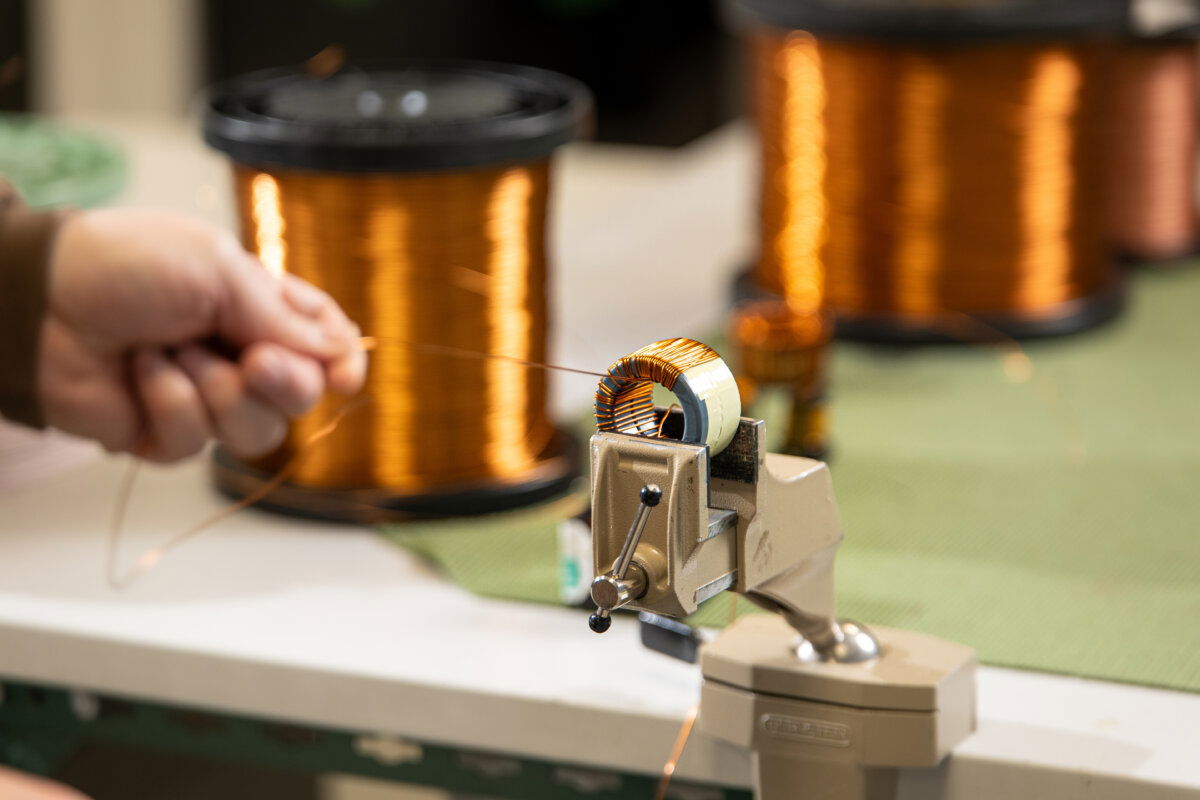

Micrometals levert hoogwaardige ijzerpoederkernen die voldoen aan de eisen van de elektronica-industrie. Micrometals is een technisch georiënteerde organisatie die poederkernoplossingen biedt met een zeer ruime keuze aan materialen, afmetingen en vormen, evenals op maat gemaakte materialen

Over Micrometals:

Met drie wereldwijde vestigingen met een totale oppervlakte van meer dan 22.300 m² is Micrometals de grootste fabrikant van gedistribueerde poederkernen. Het bedrijf formuleert zijn eigen poeders om hoge kwaliteits- en prestatienormen te garanderen en levert consistente producten aan klanten over de hele wereld. Alle vestigingen voldoen aan de hoogste ISO-normen of overtreffen deze zelfs.

Vandaag de dag ondersteunt Micrometals duizenden klanten wereldwijd in verschillende sectoren, waaronder automotive, industrie, communicatie, medische apparatuur, elektronica, huishoudelijke apparaten, defensie en lucht- en ruimtevaart, met producten die op grote schaal worden gebruikt in vermogensapplicaties en tier 1-productie

Belangrijkste feiten

- Bedrijf

- Micrometals

- Hoofdkantoor

- Verenigde Staten

- Acal BFi-partner sinds

- 2010

- Technologieën

- Poederkernen