Un fournisseur leader dans la technologie des ferrites

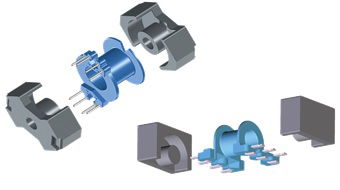

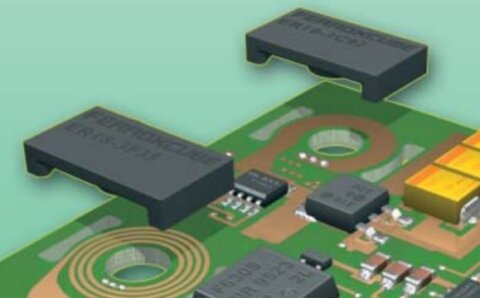

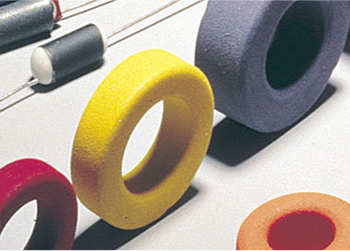

En tant que fournisseur leader dans la technologie des ferrites, Ferroxcube propose une large gamme de noyaux en ferrite tendre, d’accessoires et de produits de suppression EMI. Ils offrent également un support de conception étendu, y compris des informations d’application et des logiciels pour aider les concepteurs à optimiser leurs nouvelles conceptions.

À propos de Ferroxcube:

S’appuyant sur l’héritage de Philips Magnetic Components, Ferroxcube offre à ses clients le plus haut niveau de support dans le développement de leurs nouveaux designs innovants. En tant que principal fournisseur de technologies à base de ferrite-céramique, ils offrent une large gamme de noyaux de ferrite douce, d’accessoires et de produits de suppression EMI. Ils offrent également un soutien à l’intégration de conception, y compris des informations d’application et des logiciels pour aider les concepteurs à optimiser leurs nouveaux designs.

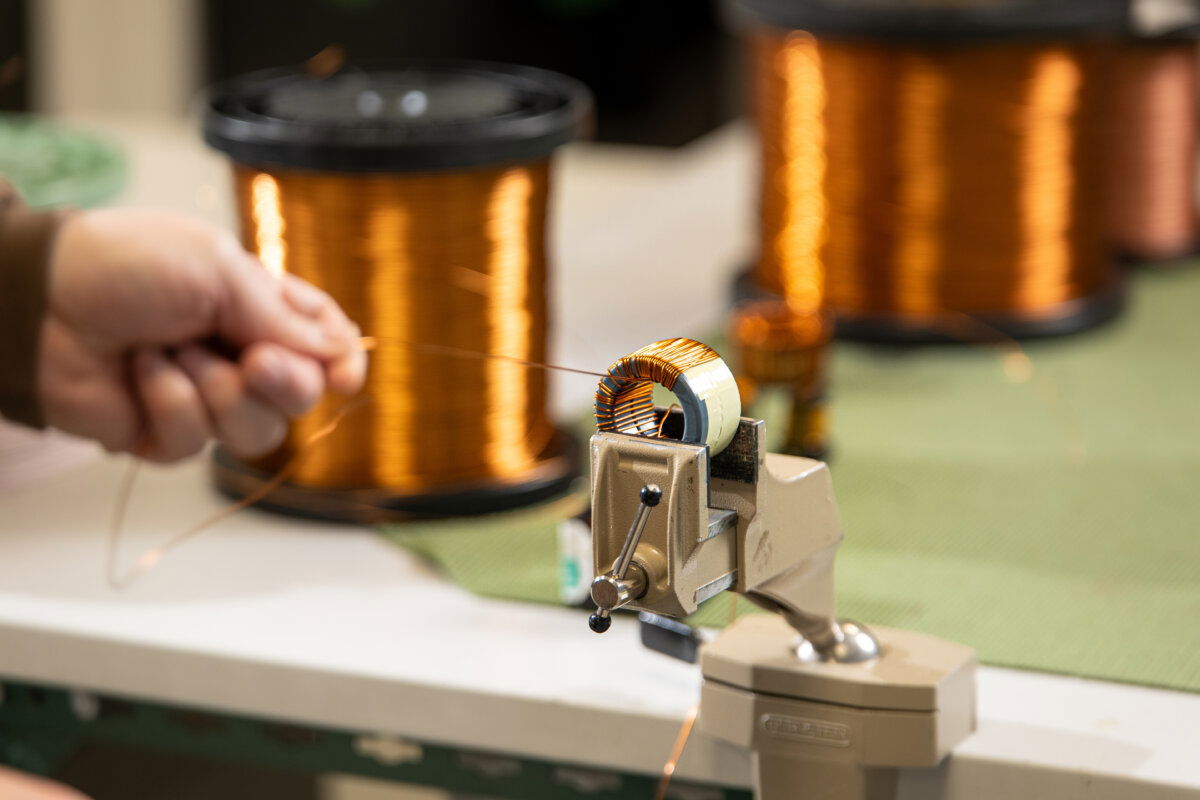

Leur solide équipe de R&D continue de développer des matériaux ayant des pertes de puissance plus faibles et des densités de flux magnétique de saturation plus élevées sur une large gamme de fréquences de fonctionnement. L’objectif de Ferroxcube est de soutenir les marchés actuels de l’électronique numérique avec des produits combinant miniaturisation et fonctionnalité toujours croissante, en utilisant leurs gammes de produits innovants et de haute qualité. Nous proposons également des services personnalisés allant de la conception à la production de composants magnétiques pour répondre à vos spécifications sur mesure.

Faits clés

- Entreprise

- Ferroxcube

- Quartier général

- Pologne

- Partenaire d'Acal BFi depuis

- ##À propos de Ferroxcube: S'appuyant sur l'héritage de Philips Magnetic Components, Ferroxcube offre aux clients le plus haut niveau de soutien dans le développement de leurs nouvelles conceptions innovantes. En tant que fournisseur leader dans la technologie céramique-ferrite, ils offrent une large gamme de noyaux en ferrite tendre, d'accessoires et de produits de suppression EMI. Ils offrent également un support de conception étendu, y compris des informations d'application et des logiciels pour aider les concepteurs à optimiser leurs nouvelles conceptions. Leur équipe de R&D solide continue de développer des matériaux ayant des pertes de puissance plus faibles et des densités de flux magnétique de saturation plus élevées sur une large gamme de fréquences de fonctionnement. L'objectif de Ferroxcube est de soutenir les marchés de l'électronique numérique d'aujourd'hui avec des produits combinant miniaturisation et fonctionnalité accrue, en utilisant leur gamme de produits innovants et de haute qualité. Nous offrons également des services personnalisés allant de la conception à la production de composants magnétiques pour répondre à vos spécifications sur mesure.

- Technologies

- Noyaux en ferrite