L’approche de tout projet d’imagerie infrarouge commence par une écoute attentive afin de s’assurer que nous comprenons parfaitement vos besoins spécifiques.

Acal BFi – Infrared Technology Centre

Nous développons des solutions infrarouges personnalisées pour vos applications

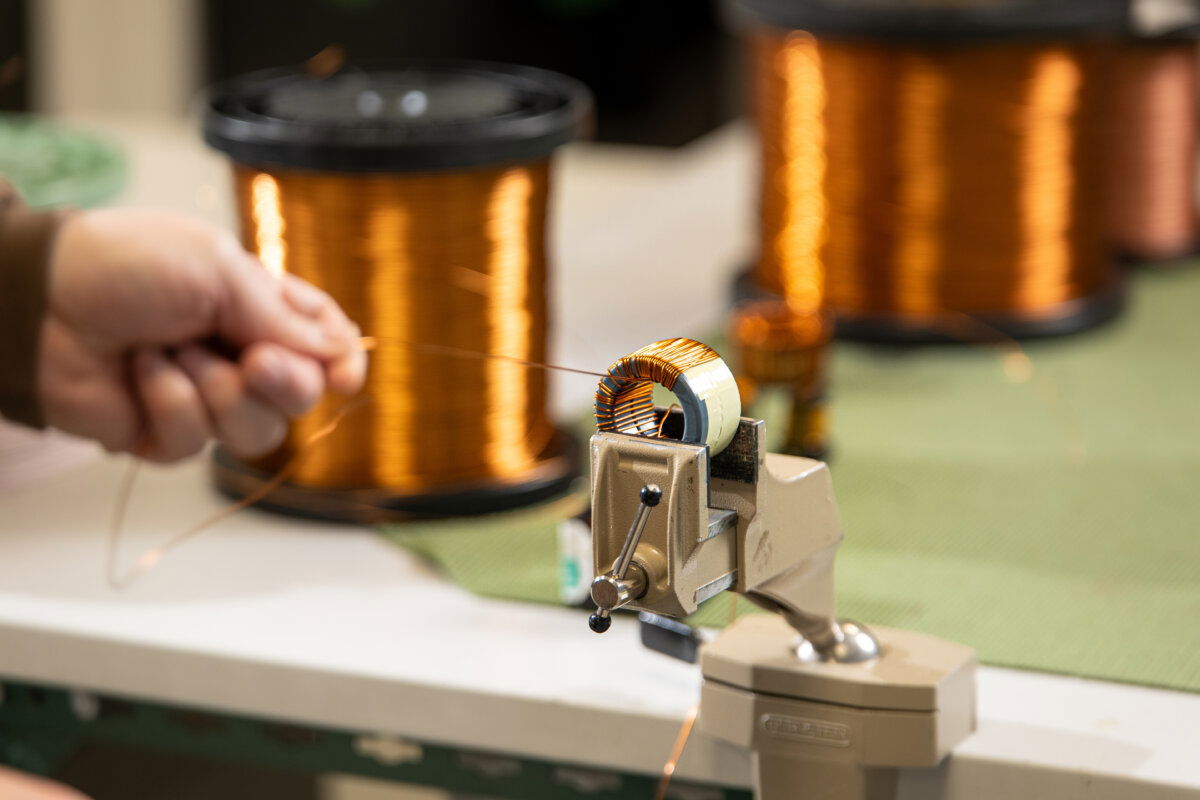

Au cours de nos quatre décennies sur le marché de l’imagerie thermique, les applications de l’imagerie infrarouge ont beaucoup changé. Elles continuent d’évoluer rapidement en raison des avantages qu’elles présentent par rapport à l’imagerie visible traditionnelle.

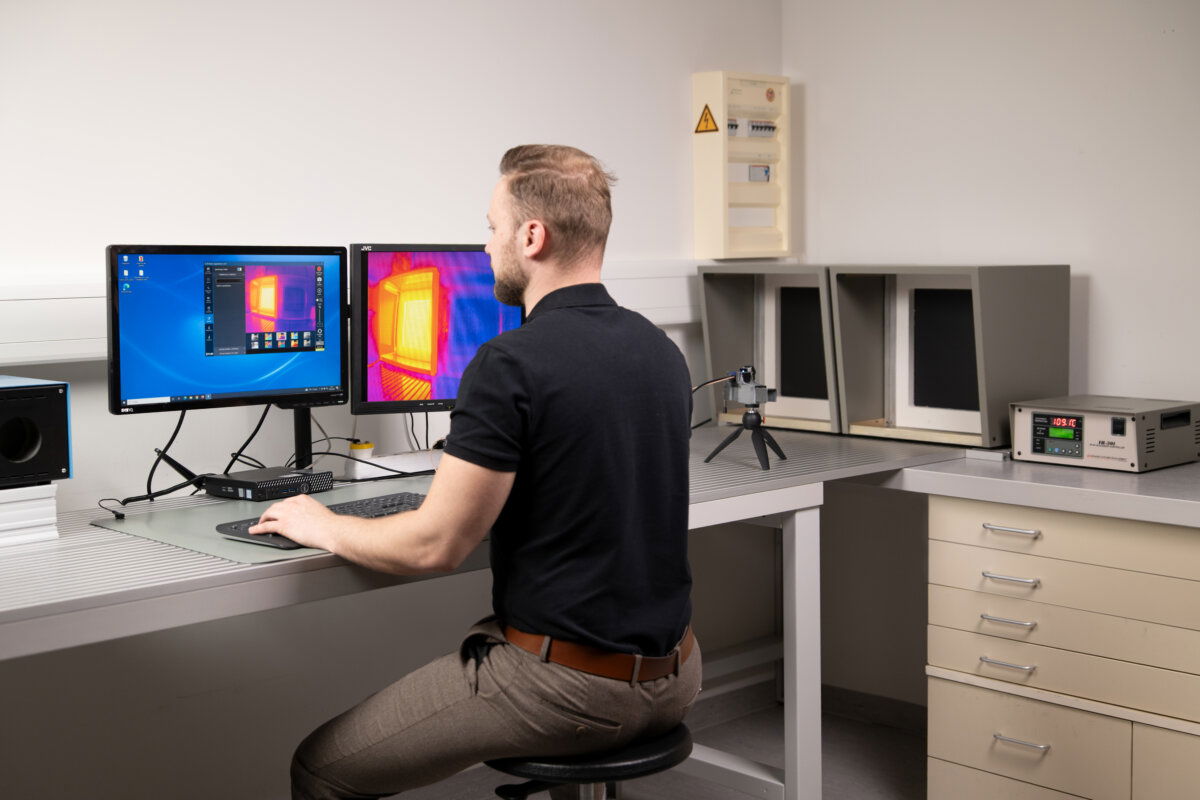

Avec une grande variété d’utilisations sur tous les marchés, de la détection précoce d’incendie dans une installation de combustible fossile ou dans une déchèterie à la vérification des températures corporelles et le contrôle de processus industriels dans l’industrie aéronautique, il est vital d’utiliser la bonne caméra. C’est là qu’intervient le Centre Technologique infrarouge.

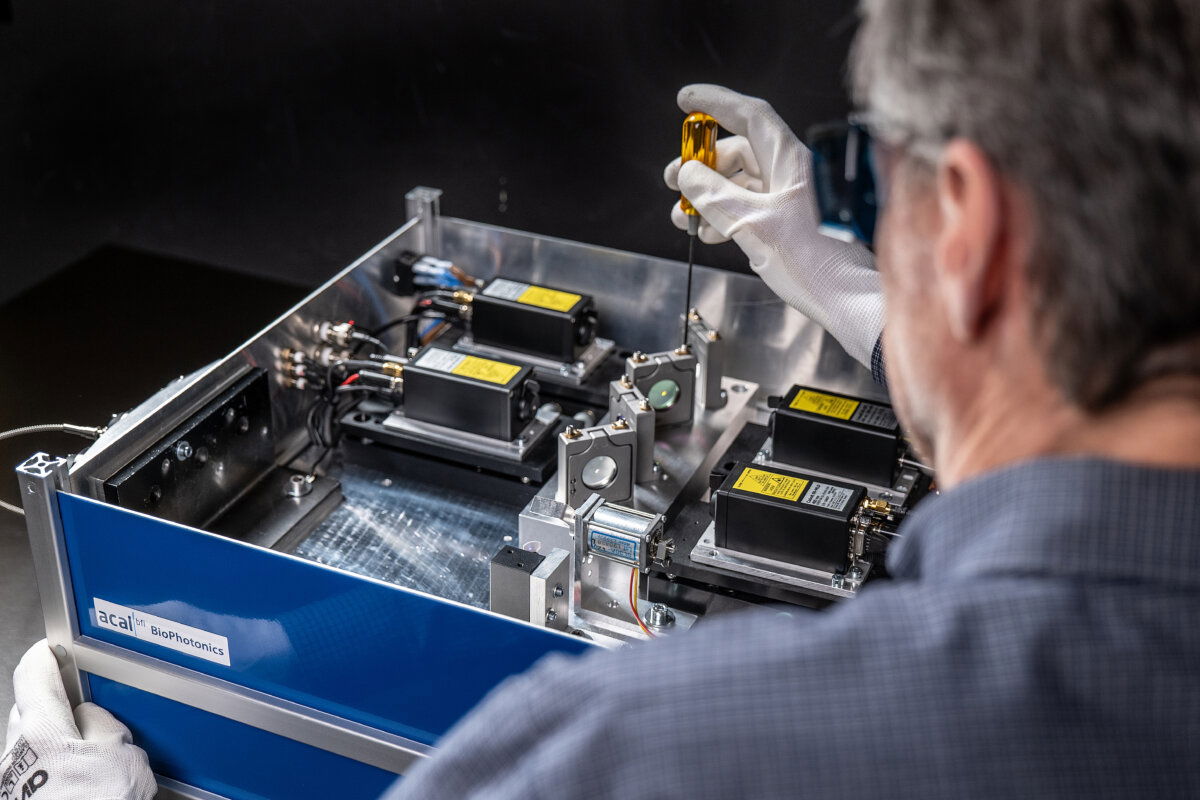

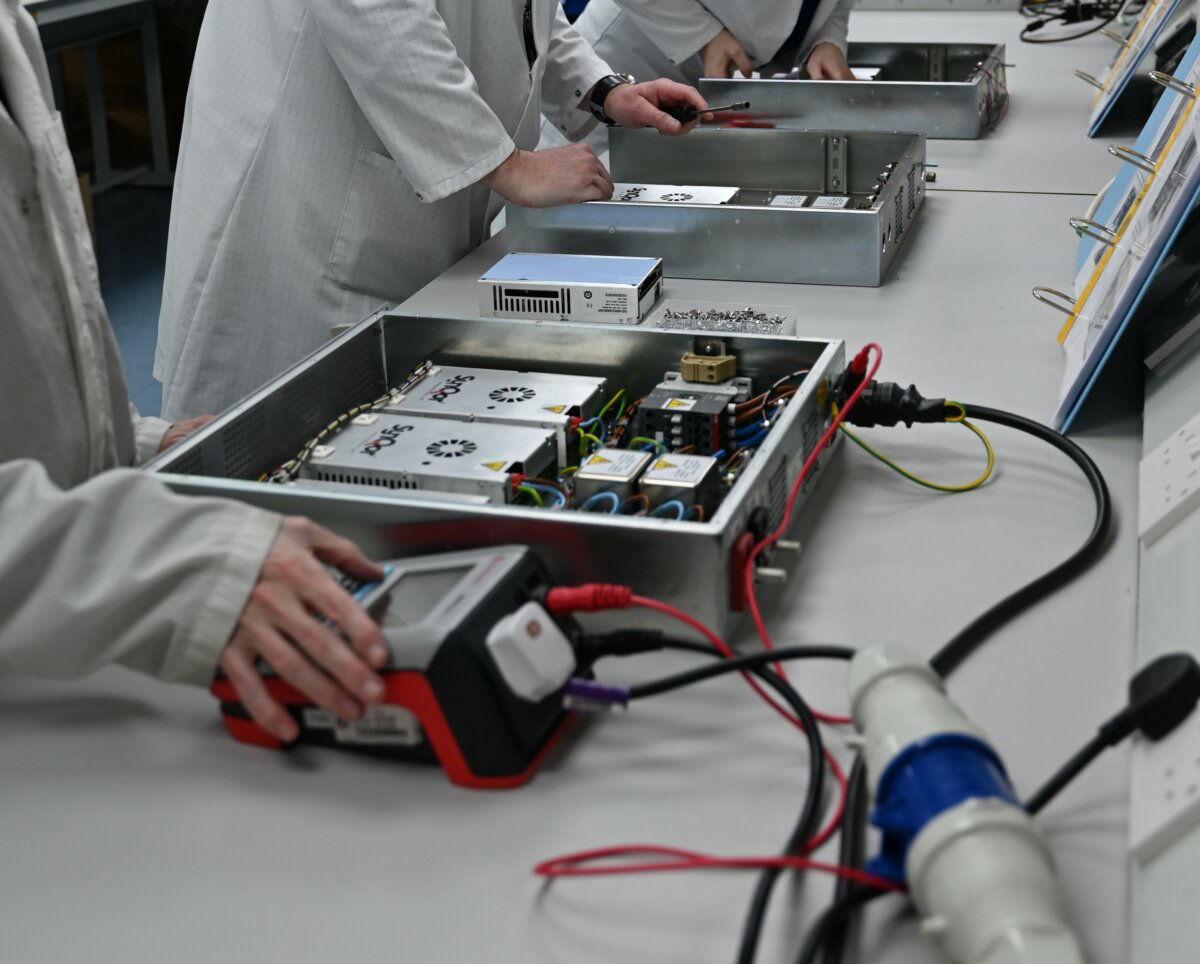

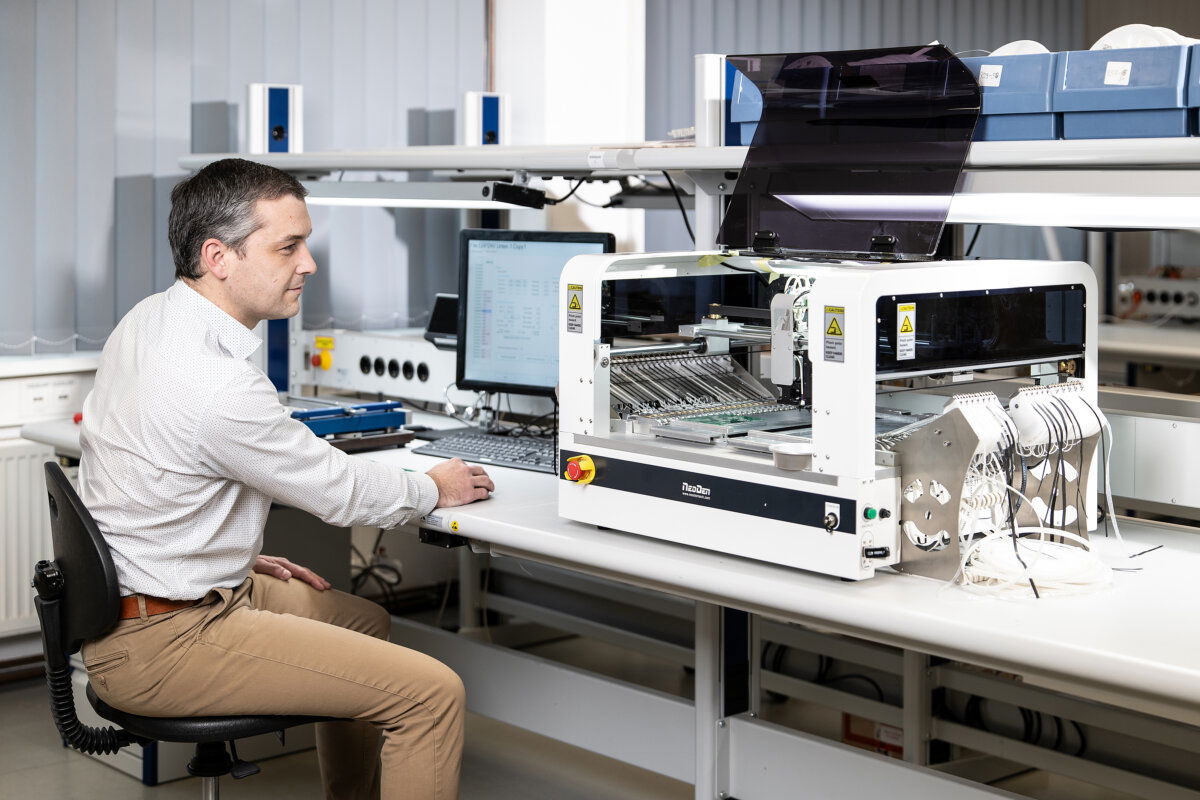

Notre équipe de spécialistes de l’infrarouge est disponible pour soutenir le développement de solutions adaptées à votre besoin, de la conception à la production, en veillant à ce que vous ayez tout ce dont vous avez besoin, quand vous en avez besoin.

L’approche de tout projet d’imagerie infrarouge commence par une écoute attentive afin de s’assurer que nous comprenons parfaitement vos besoins spécifiques. Ce n’est qu’alors que nous pouvons vous conseiller sur la technologie infrarouge la mieux adaptée – des modules thermiques et lentilles aux corps noirs et cartes de traitement – et vous aider à planifier le processus de conception, de fabrication et de test.

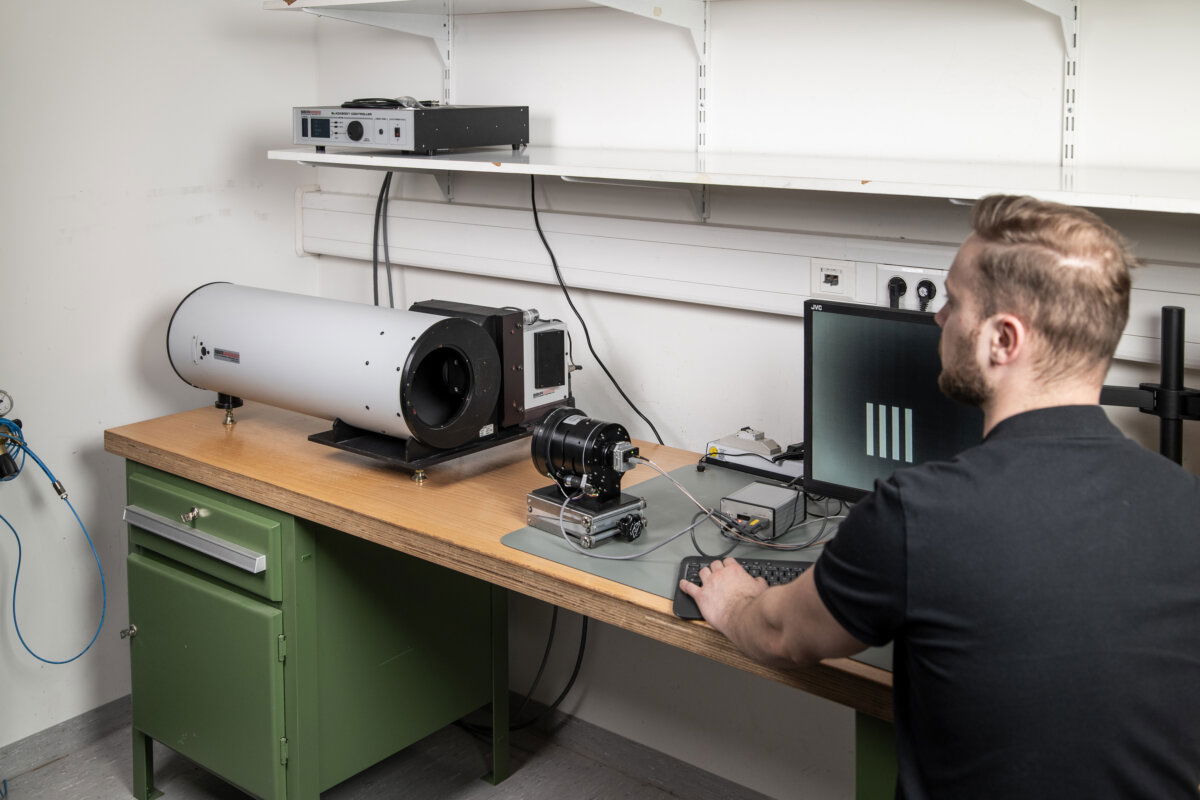

Le Centre Technologique infrarouge nous permet de fournir une assistance complète de bout en bout, et même de proposer des prêts d’équipement et des démonstrations sur le terrain afin de nous assurer que les recommandations que nous fournissons vous conviennent.

What we do at the Imaging Technology Centre?

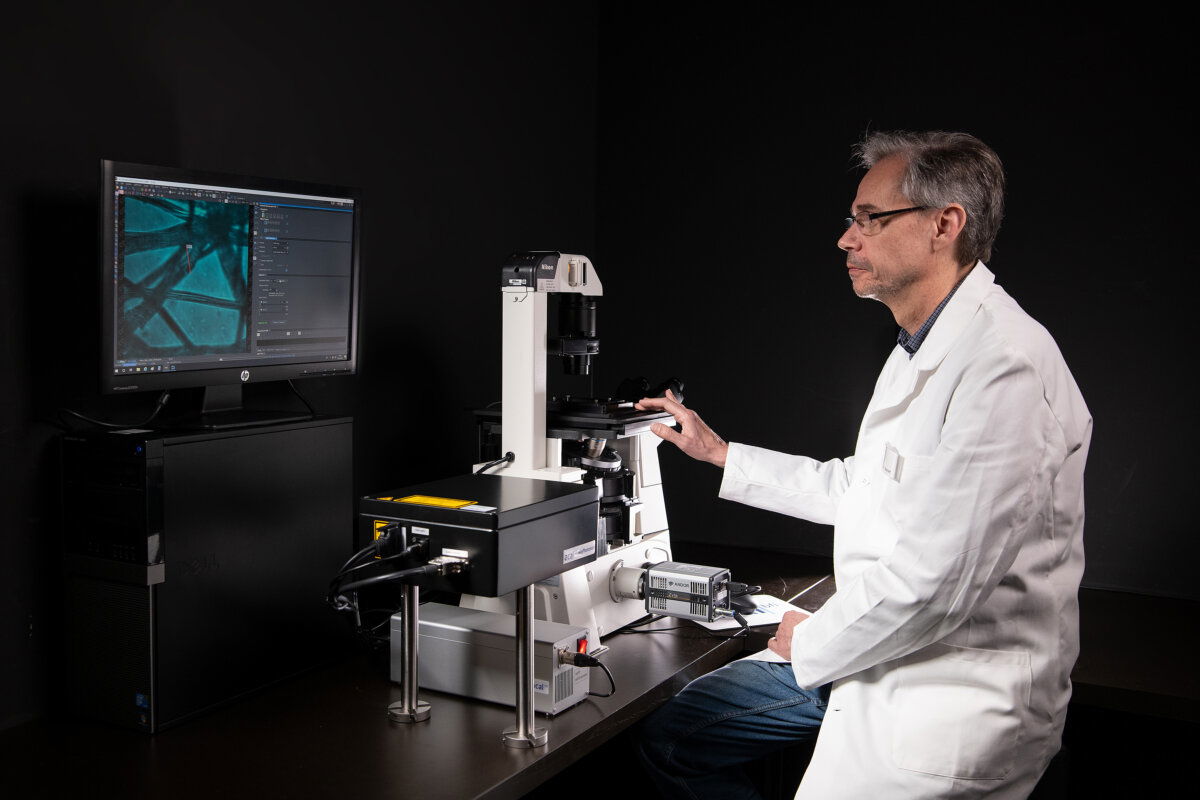

The Imaging Technology Centre focuses on delivering high-quality, application-specific infrared solutions that balance performance, accuracy, reliability, and cost.

Every project begins by listening carefully to fully understand your technical, environmental, and operational requirements. Only then can we advise on the most suitable infrared technologies, from detectors and cores to lenses, blackbodies, processing boards, and complete camera systems and help you plan the design, manufacture, and test process.

In practice, we help you to:

- Define infrared imaging requirements based on real-world operating conditions

- Select the most appropriate infrared technology for your application

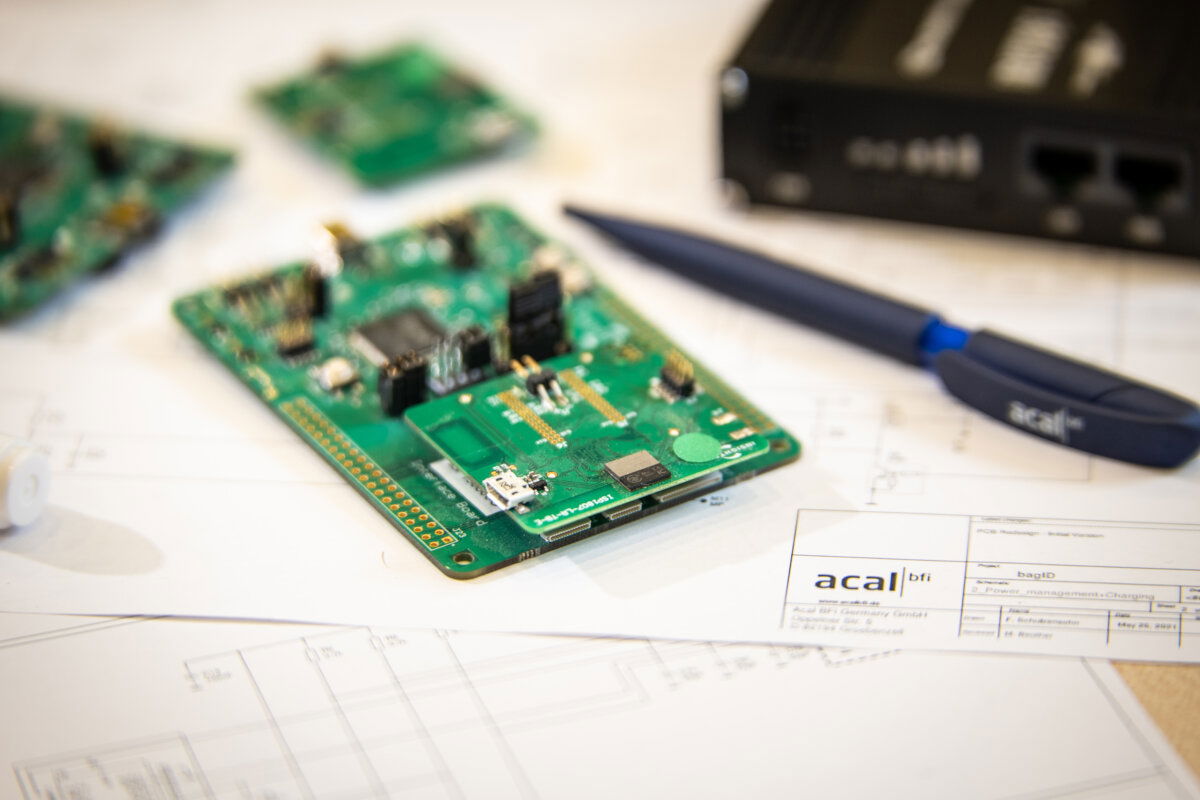

- Design and integrate custom or semi-custom infrared imaging systems

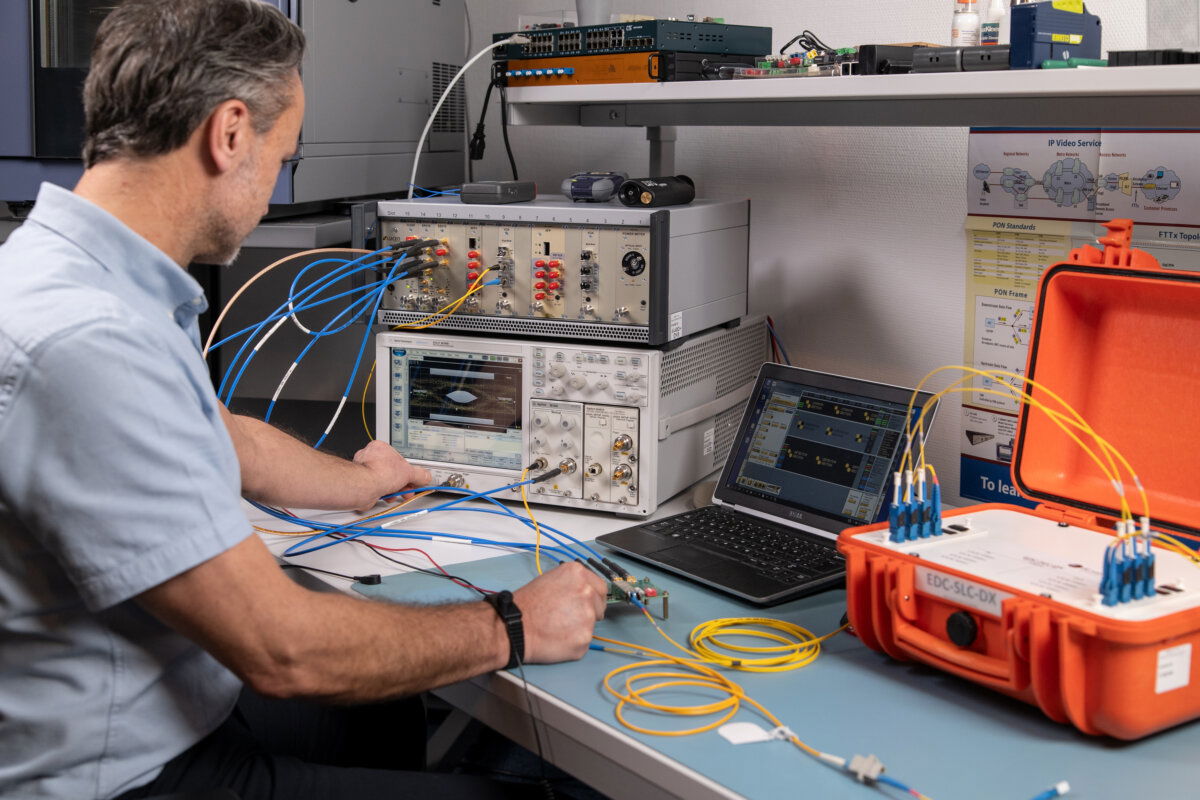

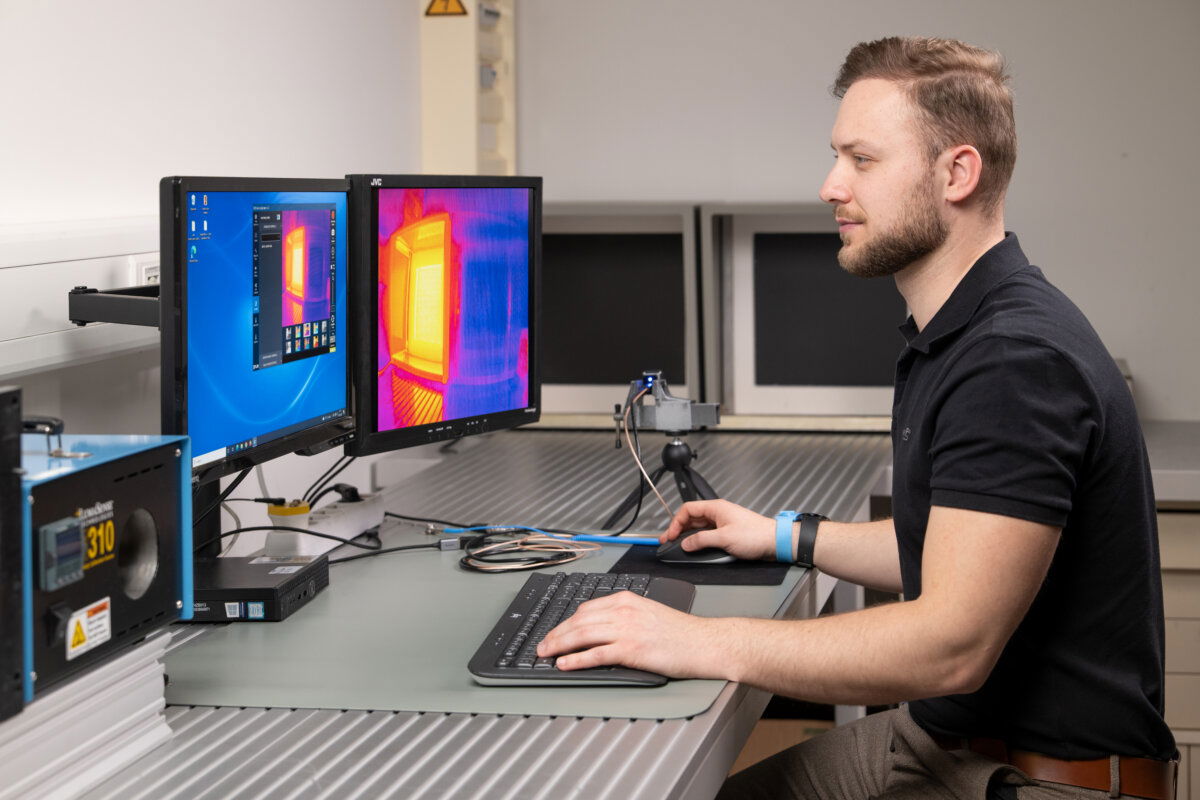

- Validate performance through specialist testing and calibration

- Reduce technical risk and accelerate time to deployment

Our role is to simplify complex infrared imaging challenges and help you deliver reliable, production-ready solutions with confidence.

Our expert team combines deep photonics and vision engineering knowledge with access to a broad portfolio of infrared cameras, sensors, optics, laser sources, illumination, and advanced imaging technologies. We help you select the right sensor architecture, optimise optical performance, overcome environmental and integration challenges, and navigate complex compliance requirements for industrial, medical, and defence applications.

Capacités infrarouges

Au sein du Centre Technologique infrarouge, nous pouvons offrir une gamme de services pour vous aider à créer vos solutions personnalisées de haute qualité.

Specialist Imaging Technology Centre capabilities

From configurable subsystems to fully bespoke imaging solutions – comprehensive support for your imaging requirements.

Navigating the complexities of imaging system design can be challenging. Whether you require a configurable camera module, a semi-custom optical adaptation, or a fully bespoke infrared or vision system engineered to your precise performance criteria, the Imaging Technology Centre provides a complete spectrum of specialist support.

From sensor selection and optical optimisation to processing architecture, calibration, testing, and environmental integration, we work alongside your engineering team to deliver imaging solutions that meet demanding technical, operational, and regulatory requirements.

Collaborative expertise across Acal BFi Technology Centres

The Imaging Technology Centre works closely with our other Technology Centres to deliver fully integrated system solutions. When additional specialist support is required, we can engage teams from the other Technology Centres to provide a complete, cross-technology offer. By leveraging a portfolio of advanced imaging, sensor, optics, wireless, and power technologies, we are able to deliver solutions that address the evolving challenges of modern industrial, defence, medical, and research applications.

Why work with the Imaging Technology Centre?

The Infrared Imaging Technology Centre is designed to support engineers and technical decision-makers at every stage of infrared system development, offering:

- Specialist infrared expertise backed by decades of experience

- Engineering-led support from concept through deployment

- Reduced technical and certification risk

- Access to specialist testing, calibration, and demonstration facilities

- A collaborative partner, not just a component supplier

Why Acal BFi? Your partner for imaging solutions

With decades of experience supporting advanced sensing and imaging technologies, Acal BFi combines deep technical expertise with access to a broad supplier ecosystem to deliver application-matched infrared solutions.

We provide:

- Hands-on engineering consultation

- Technology and component selection

- Custom and semi-custom infrared system design

- Testing, calibration, and compliance support

- Long-term lifecycle and supply chain management

Supported by centralised logistics and a pan-European engineering network, we help ensure reliable supply, technical continuity, and confidence throughout your product’s lifecycle.

Selection depends on factors including temperature range, sensitivity, resolution, environmental conditions, and regulatory requirements. Our specialists help define these parameters and recommend the most suitable technology.

Custom solutions are typically required when standard cameras cannot meet performance, form factor, environmental, or integration requirements, or when system-level optimisation is critical.

Yes. We offer specialist testing, equipment loans, and field demonstrations to validate performance in real-world conditions before final design or production decisions are made.

By supporting technology selection, system design, testing, and compliance early in the development process, we help minimise redesigns, certification delays, and performance issues later in the project.