Jump to:

Need to speak with an expert?

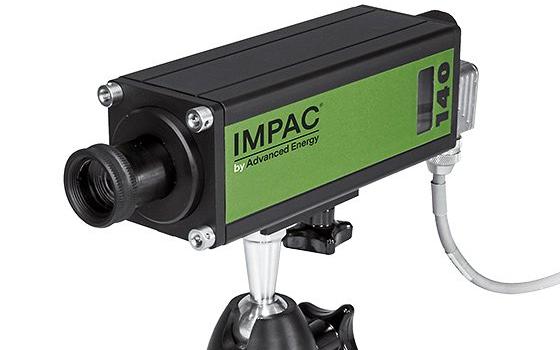

Pyrometers

When looking for a pyrometer, quality and accuracy should be at the forefront of your requirements. Lumasense’s pyrometer range has been built up over years of research and customer contact to support engineers on almost any application, with the ability to customise solutions for challenging applications.

Specific to the glass industry’s specific requirements, Lumasense offers a range of non-contact pyrometers. Whether you need a pyrometer for flat glass, solar glass, container glassware, utility glassware, or technical glass, their products deliver extremely fast and highly accurate temperature readings.

In steel-making processes, the demand for more accurate and consistent temperature control is increasing due to quality standards and higher energy costs. Their pyrometers for metal applications provide best-in-class technology, ease of use, and reliability.

For production monitoring within industrial markets, accurate temperature measurement is critical as it's important to keep costs down and product quality high. Lumasense’s solutions provide cutting-edge technology that meets challenging design requirements.

Their petrochemical sensors provide highly accurate infrared temperature data, with refineries, gas plants, and petrochemical companies choosing Lumasense for their offering. Delivering superior performance, cost savings, and proven experience, their petrochemical sensors have over 1,700 installations worldwide.

Lumasense’s optical fibre thermometers are field-proven and deliver real-time measurement that optimises process control through in-situ probes.

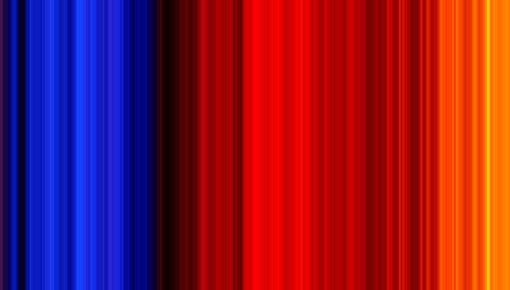

Thermal imagers and systems

Lumasense’s thermal imagers and systems use highly dependable infrared technology to accurately measure temperatures and temperature distribution of small and fast-moving objects.

Using special mid-wave infrared detectors, the BoilerSpection MB can see through flames and provides stable and extremely clear through-flame images in boilers, furnaces, kilns, or incinerators.

The BoilerSpection SD is the ideal turnkey solution for continuous infrared imaging inside boilers and furnaces. By providing clear, informative through-flame imaging, you can proactively manage your boilers and significantly improve uptime.

Suitable for applications with multiple flare tips, Lumasense’s FlareSpection system provides pilot flame monitoring, with remote flare operation to enable you to detect differences in flare stack heat signatures.

The FurnaceSpection delivers real-time continuous temperature measurement to detect process abnormalities inside high-temperature furnaces in refining, metals, and glass production processes. Inside natural gas-fired furnaces, it measures the temperature of the product, refractory, and heat transfer surfaces.

Ideal for a broad range of demanding real-time imaging applications, the Mikron MC320 series is cost-efficient, offers superior performance, and is a non-contact infrared imager.

Operating between -40 and 1600°C, the Mikron MCL 640 is suitable for demanding industrial and manufacturing applications due to its unparalleled accuracy, with its stand-out features being advanced, maintenance-free electronics, and industrial protective packaging.

Lumasense’s Mikron MCS 640 measures temperature between 600 and 3000°C. These offer shortwave infrared thermal imaging with internal digital signal processing, suitable for graphite, ceramics, and metallic-surface applications.

Featuring remote fault detection and alarm generation, and immediate analysis of dynamic conditions, the ThermalSpection 724 is a complete turn-key system for automated, continuous thermal imaging for substations and industrial sites.

Using non-contact thermal imaging, the ThermalSpection CVM offers a turn-key solution for monitoring critical vessels. Its main features include early fault detection, continuous, automated monitoring, and easy integration into existing plant DCS and data historian.

Calibration sources

Lumasense’s blackbodies accurately verify the output signals of your pyrometers, thermal imaging systems, heat-flux measurement systems, and spectrographic analysis systems.

Mikron® calibration sources ensure high quality and dependability through use tests, burn-in times, and pyrometric calibrations. Their low-temperature blackbody solutions are compliant with national standards.

These Mikron® calibration sources help to support the accuracy and reliability of your thermal products and systems. Featuring superior emissivity values, fast heat-up times, and temperature stability.

Rapidly verify output signals of your thermal products and systems with Mikron® calibration sources. These high-temperature blackbodies feature superior emissivity values, fast heat-up times, and high-temperature stability.

Technical news and insights

Access industry news and Acal BFi articles, white papers and brochures

Enquire

Submit your enquiry directly to one of our Technical Sales Specialists.

Alternatively call our Sales Team.

Mandatory fields*

Our approach

When it comes to developing custom solutions for tomorrow's technologies, we trust our approach to deliver the best possible outcome.

Our engineers will skilfully guide you through each stage of your project, working with you to understand and identify a solution that meets your technical and commercial needs before designing and integrating your solution.

Belgium

Belgium